Introduction to Stamping Die Parts

Stamping die parts may not be the most glamorous aspect of manufacturing, but they play a crucial role in ensuring product quality. From automotive components to household appliances, these small yet mighty parts are responsible for shaping and forming metal sheets into precise shapes and sizes. Without high-quality stamping die parts, manufacturers run the risk of producing subpar products that fall short in terms of accuracy, durability, and overall performance.

In this blog post, we will delve into the world of stamping die parts and explore their impact on product quality. We'll discuss why investing in reliable stamping die parts is essential for manufacturers, explore common types of dies and their functions, highlight factors affecting their quality, and shed light on the benefits that come with using top-notch stamping die components.

So buckle up as we take a deep dive into the fascinating realm of ADAQIAO Machinery - where precision meets perfection!

The Importance of High-Quality Stamping Die Parts in Manufacturing

In the world of manufacturing, precision and efficiency are paramount. Every single component that goes into a product plays a crucial role in its overall quality. One such component that often goes unnoticed but is absolutely essential is the stamping die part.

Stamping die parts serve as the backbone of many manufacturing processes. They are responsible for shaping and forming materials into desired shapes with accuracy and consistency. Without high-quality stamping die parts, manufacturers would face numerous challenges that could compromise their products' integrity.

Using low-quality stamping die parts can lead to inconsistencies in product dimensions and tolerances. This can result in misaligned or poorly fitting components, making it difficult to assemble finished products correctly. High-quality stamping dies ensure precise cuts, bends, and forms every time, ensuring uniformity throughout the production process.

Inferior stamping die parts may be more prone to wear and tear over time due to inadequate material strength or poor craftsmanship. This can lead to premature failure of the tools during operation, causing costly downtime for repairs or replacement.

Moreover, using subpar stamping dies increases the risk of defects in manufactured products. Any imperfections on stamped components can negatively impact their functionality or aesthetics – leading to customer dissatisfaction and potential recalls.

Furthermore, investing in high-quality stamping die parts also contributes directly to increased productivity on the factory floor. When operators have reliable tools at their disposal, they can work efficiently without interruptions caused by tool breakdowns or rework due to poor quality outputs.

Lastly but certainly not least important is safety – an aspect never overlooked when discussing product quality within manufacturing processes. Low-quality stamping dies could pose safety hazards if they fail unexpectedly during operation – potentially injuring workers or damaging other equipment nearby.

To ensure consistent output quality while maintaining operational efficiency and worker safety standards; adaqiao Machinery highly recommends utilizing only top-notch stamping die parts from reputable suppliers who prioritize precision engineering techniques combined with superior raw materials. By doing so, manufacturers can guarantee the highest level of product quality and

Common Types of Stamping Dies and Their Functions

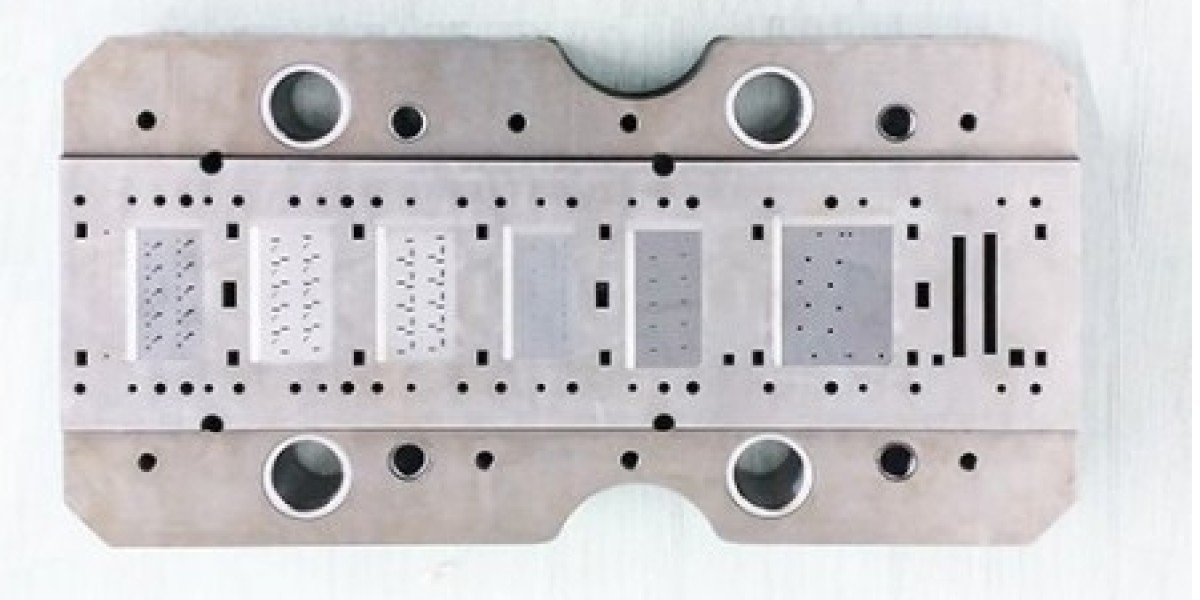

Stamping dies are essential tools used in the manufacturing industry to shape and form materials into desired shapes. There are various types of stamping dies, each designed for specific purposes. Let's explore some common types and their functions.

1. Blank die: This type of die is used to cut out the required shape from a metal sheet or strip, leaving behind the desired workpiece.

2. Piercing die: As the name suggests, this type of die is utilized to create holes or openings in the material by removing a portion of it.

3. Forming die: These dies have cavities that help bend or deform the material into different shapes according to product specifications.

4. Progressive die: This complex type of die performs multiple operations on a single sheet while it moves through various stations, resulting in efficient production processes.

5. Drawing die: Used primarily for creating cylindrical or cup-shaped components by pulling material through an opening using force applied from punch presses.

6. Bending die: With specialized tooling, these dies enable precise bending operations on materials such as metal sheets or tubes at predetermined angles.

7. Coining Die: Utilized for creating intricate designs or embossments on surfaces with high accuracy and precision.

Each type of stamping die plays a crucial role in achieving accurate dimensions, smooth finishes, and consistent quality throughout the manufacturing process.

Top Factors Affecting Stamping Die Part Quality

Precision is paramount in the manufacturing industry, and stamping die parts play a crucial role in achieving it. However, several factors can affect the quality of these essential components. Let's delve into some of the top factors that manufacturers need to consider for ensuring high-quality stamping die parts.

Material Selection: The choice of material greatly influences the performance and durability of stamping die parts. Opting for high-quality materials with excellent strength and wear resistance can significantly enhance their lifespan.

Design Complexity: The complexity of the design also plays a significant role in determining the quality of stamping die parts. Intricate designs require more precision during manufacturing, increasing the chances of errors or defects if not handled properly.

Manufacturing Process: The method employed to manufacture stamping die parts directly affects their quality. Utilizing advanced technologies such as CNC machining and computer-aided design (CAD) ensures greater accuracy and consistency throughout production.

Maintenance Practices: Regular maintenance is vital for preserving the functionality and extending the lifespan of stamping dies. Neglecting proper maintenance can lead to premature wear and tear, resulting in decreased product quality over time.

Quality Control Measures: Implementing stringent quality control measures at every stage of production helps identify any issues or defects early on. Thorough inspections, testing procedures, and adherence to industry standards are critical for maintaining high standards in stamped part manufacturing.

By taking these factors into account when sourcing or producing stamping die parts, manufacturers can ensure superior product quality while minimizing downtime caused by faulty components. Investing in reliable suppliers like adaqiao Machinery who prioritize precision engineering will undoubtedly yield better results in terms of both performance and longevity

Benefits of Using High-Quality Stamping Die Parts for Product Quality

Stamping die parts play a crucial role in ensuring the quality of manufactured products. Using high-quality stamping die parts can have numerous benefits for product quality.

First and foremost, high-quality stamping die parts are designed to provide precision and accuracy in shaping metal components. This ensures that the final products meet the required specifications and dimensions, resulting in consistent product quality.

Furthermore, using top-notch stamping die parts enhances the overall efficiency of the manufacturing process. These parts are built to withstand heavy usage and minimize wear and tear, leading to reduced downtime for maintenance or replacement. As a result, manufacturers can achieve higher productivity levels while maintaining consistent product quality.

In addition, high-quality stamping die parts offer superior durability and longevity. They are made from durable materials that can withstand repetitive use without compromising their structural integrity. This means that manufacturers can rely on these parts for extended periods without worrying about frequent replacements or repairs.

Moreover, using high-quality stamping die parts allows manufacturers to optimize their production processes. These parts often incorporate advanced features such as quick-change capabilities or automated functions, which streamline production workflows and reduce human error. By optimizing the manufacturing process, companies can enhance both efficiency and product quality simultaneously.

Investing in high-quality stamping die parts is essential for ensuring better product quality across various industries such as automotive manufacturing, electronics production, or appliance fabrication. The precision, durability, efficiency-boosting capabilities of these components contribute significantly to producing consistent products that meet customer expectations.

Conclusion: Investing in Quality Stamping Die Parts for Better Product Quality

Investing in quality stamping die parts is crucial for achieving better product quality. By using high-quality stamping dies, manufacturers can ensure precision, accuracy, and consistency in their production processes. These parts play a significant role in shaping various materials into desired forms, making them essential components of any manufacturing operation.

The importance of high-quality stamping die parts cannot be overstated. They directly impact the final product's overall quality by influencing factors such as dimensional accuracy, surface finish, strength, and durability. With well-designed and properly maintained stamping dies, manufacturers can produce products that meet or exceed customer expectations.

There are different types of stamping dies available for various applications. Each type serves a specific purpose and requires specific components to function optimally. Whether it's a blanking die used for cutting out flat pieces from sheet metal or a forming die used to shape material into three-dimensional objects, the quality of the die parts directly affects the performance and output.

Several factors affect the quality of stamping die parts. Material selection is critical as using low-quality materials can lead to premature wear and decreased performance. The design and construction of the dies also influence their longevity and performance capabilities. Regular maintenance and proper lubrication are necessary to ensure optimal functioning over time.

Using high-quality stamping die parts brings numerous benefits to manufacturers seeking superior product quality. It enables greater precision in shaping materials with tight tolerances consistently. This reduces scrap rates while improving efficiency and productivity on the production line.

Good-quality stamps help achieve excellent surface finishes on finished products by minimizing defects like burrs or rough edges during the forming process.

Furthermore, investing in reliable stamping dies ensures longer tool life due to increased durability against wear-and-tear caused by repetitive use or harsh operating conditions.

Lastly but certainly not least important—by utilizing top-notch stamped components—manufacturers enhance customer satisfaction through delivering consistent quality products that meet or exceed expectations every time.