Fuel cells are a promising technology for generating clean and efficient energy. One of the key components of a fuel cell is the membrane electrode assembly (MEA), which plays a critical role in the electrochemical reactions that produce electricity. The MEA consists of a proton exchange membrane (PEM) sandwiched between two electrodes, typically made of platinum. Understanding the function and performance of the MEA is essential for optimizing fuel cell design and improving overall efficiency. In this article, we will explore the role of the MEA in fuel cells and its importance in the development of sustainable energy solutions.

What is Membrane Electrode Assembly (MEA)?

Membrane Electrode Assembly (MEA) is a critical component in fuel cell technology, acting as the core element that enables efficient energy conversion. It consists of three primary components: a proton exchange membrane (PEM), an anode electrode, and a cathode electrode.

The PEM serves as the central barrier between the anode and cathode compartments, allowing only charged ions to pass through while preventing gas crossover. This selective permeability ensures proper functioning of the fuel cell system.

The anode electrode facilitates the oxidation reaction by breaking down hydrogen molecules into protons and electrons. These protons then move through the PEM towards the cathode side.

On the other hand, at the cathode electrode, oxygen combines with these protons to produce water or other oxidization products depending on specific applications. The electrons released during this process travel externally via a circuit to generate electrical power before reuniting with protons at the cathode side.

Together, these components form a tightly integrated MEA structure that efficiently converts chemical energy into usable electricity without harmful emissions or byproducts. By optimizing each component's performance, researchers are constantly striving to enhance overall fuel cell efficiency and durability.

In short, MEA acts as both a physical separator and catalyst within fuel cells - enabling efficient ion transport while promoting electrochemical reactions necessary for generating clean energy. Understanding its role is crucial for advancing fuel cell technology towards widespread commercial deployment across various industries.

Components of MEA and their Functions

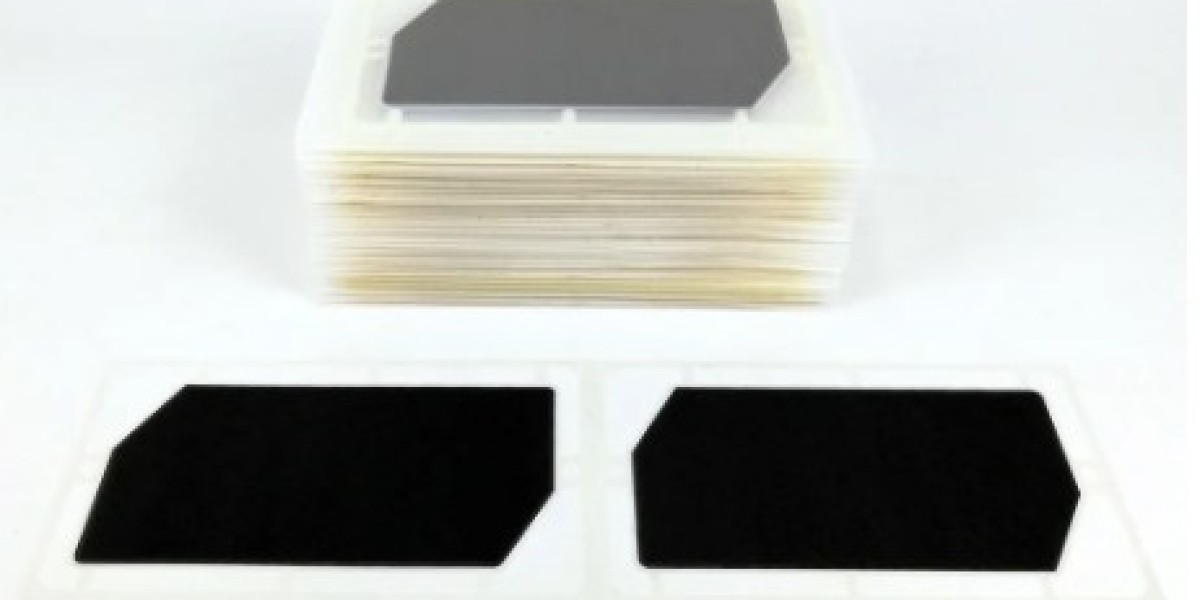

The Membrane Electrode Assembly (MEA) is a crucial component in fuel cells, responsible for converting the chemical energy stored in fuels into electrical energy. The MEA consists of three main components: the catalyst layers, the proton exchange membrane (PEM), and the gas diffusion layers.

The catalyst layers play a vital role in facilitating electrochemical reactions within the fuel cell. They are typically made up of platinum or other metal alloys that act as catalysts to speed up these reactions. These layers help separate hydrogen ions from electrons during oxidation and reduction processes.

The proton exchange membrane acts as a barrier between the anode and cathode compartments of the fuel cell. It allows protons to pass through while preventing electrons from flowing freely, thus creating an electric potential difference across it.

Gas diffusion layers provide structural support to the MEA and allow reactant gases, such as oxygen or hydrogen, to evenly distribute across its surface. They also assist in water management by allowing excess moisture produced during operation to escape.

Each component within the MEA works harmoniously together to ensure optimal performance of fuel cells. By facilitating efficient electrochemical reactions, enabling ion transport, and managing reactant distribution, they contribute significantly to overall fuel cell efficiency.

Understanding how each component functions within the MEA is essential for improving its design and enhancing fuel cell performance. Ongoing research aims at developing more cost-effective materials with higher catalytic activity while maintaining durability.

As we delve deeper into understanding these components' roles within MEMS assemblies, we uncover new possibilities for enhancing renewable energy solutions powered by fuel cells.

The Importance of MEAs in Fuel Cell Performance

Fuel cells have emerged as a promising alternative to traditional energy sources, offering clean and efficient power generation. At the heart of these fuel cells lies the Membrane Electrode Assembly (MEA), playing a crucial role in their performance.

The MEA consists of three key components: the proton exchange membrane (PEM), anode catalyst layer, and cathode catalyst layer. Each component has its own unique function that contributes to the overall functioning of the fuel cell.

The PEM acts as a barrier between the anode and cathode compartments, allowing only protons to pass through while blocking electrons. This selective permeability is vital for maintaining proper ion transport within the fuel cell.

Both the anode and cathode catalyst layers are responsible for facilitating electrochemical reactions. The anode catalyst oxidizes hydrogen fuel into protons and electrons, while at the cathode side, oxygen combines with protons and electrons to form water.

The efficiency and performance of these individual components directly impact overall fuel cell performance. Any degradation or inefficiencies within them can result in reduced power output or even failure of the entire system.

Therefore, optimizing MEA design plays a critical role in enhancing fuel cell efficiency and durability. Researchers are continuously exploring new materials and manufacturing techniques to improve catalytic activity, increase durability, reduce costs, and minimize environmental impacts.

Recognizing the significance of MEAs is essential when considering advancements in fuel cell technology. By understanding how each component functions together harmoniously within this assembly, we can unlock greater potential for cleaner energy solutions that contribute towards a sustainable future

Applications of MEA in Fuel Cells

Fuel cells are a promising technology that offers a clean and efficient way to generate electricity. One crucial component of fuel cells is the Membrane Electrode Assembly (MEA), which plays a vital role in their performance. The MEA consists of three main components: the proton exchange membrane, anode catalyst layer, and cathode catalyst layer.

One significant application of MEAs is in transportation. Fuel cell vehicles powered by hydrogen are gaining traction as an environmentally friendly alternative to traditional internal combustion engines. The MEA enables the conversion of hydrogen gas into electrical energy, powering the vehicle's motor and producing only water as a byproduct.

Another area where MEAs find applications is in portable power devices. From smartphones to laptops and even camping equipment, fuel cells offer a lightweight and long-lasting source of energy for various electronic devices. With advancements in MEA technology, these portable fuel cells can provide extended operation times without compromising on performance.

Furthermore, stationary power generation systems also benefit from using MEAs. These systems utilize fuel cell stacks with multiple interconnected MEAs to generate electricity for residential or commercial buildings. They provide reliable backup power during grid outages and contribute towards reducing greenhouse gas emissions.

In addition to these primary applications, researchers are exploring other potential uses for MEMs in areas such as aerospace, military operations, and remote sensing devices.

The versatility and efficiency offered by MEMs make them indispensable in various industries striving for cleaner energy solutions. As research continues to advance this technology further, we can expect more innovative applications emerging that harness the potential of MEMs for sustainable energy generation.

Conclusion

In this article, we have delved into the intricate world of fuel cells and explored the vital role played by Membrane Electrode Assembly (MEA) in their performance. MEA serves as the heart of a fuel cell, enabling efficient electrochemical reactions that convert chemical energy into electrical energy.

We have learned about the components of MEA, including the proton exchange membrane, catalyst layers, and gas diffusion layers. Each component plays a crucial role in facilitating the movement of ions and electrons within the fuel cell system.

Understanding how these components work together to form MEA is essential for optimizing fuel cell performance. By carefully selecting materials, designing optimal structures, and controlling manufacturing processes, researchers can enhance factors such as power density, efficiency, durability, and cost-effectiveness.

The applications for MEAs in various sectors are vast and promising. From transportation to portable electronics to stationary power generation systems – fuel cells equipped with high-performance MEAs offer an environmentally friendly alternative to traditional energy sources.

As technology continues to advance and research efforts progress further in this field, it is clear that membrane electrode assembly will continue to play a pivotal role in driving innovation towards more sustainable energy solutions.