Defoaming Coating Additives Industry

Summary:

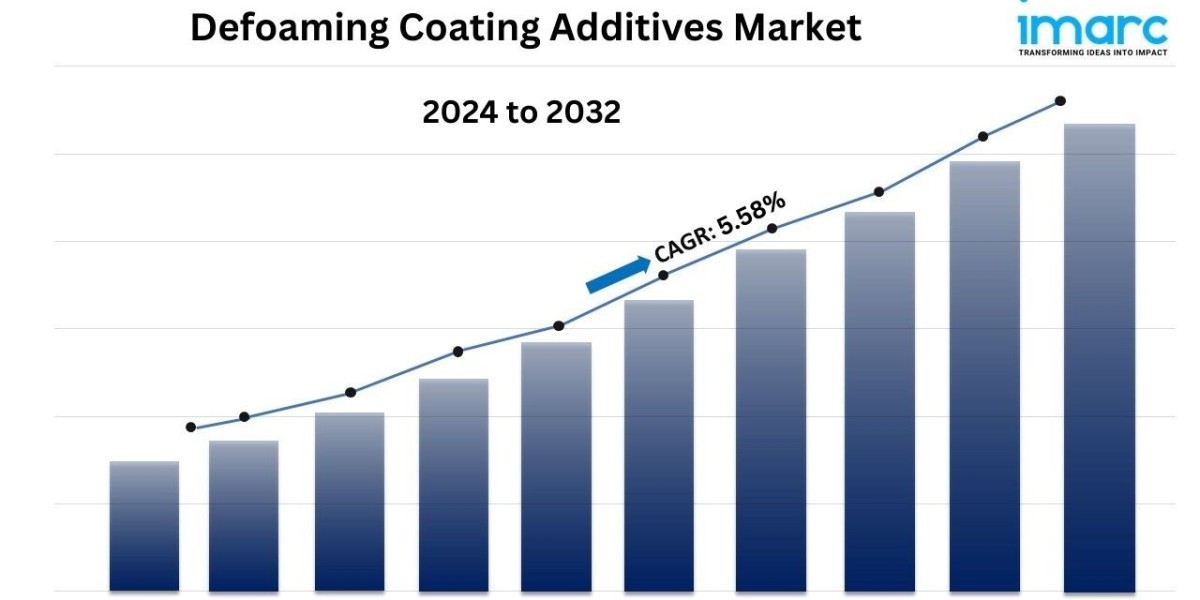

● The global defoaming coating additives market size reached USD 1.33 Billion in 2023.

● The market is expected to reach USD 2.16 Billion by 2032, exhibiting a growth rate (CAGR) of 5.58% during 2024-2032.

● Asia Pacific leads the market, accounting for the largest defoaming coating additives market share.

● Water-based systems, including silicone, account for the majority of the market share in the product type segment as they are highly effective in foam control, ensuring a smooth, defect-free finish in water-based coatings.

● Based on the function, the market has been segmented into foam breaking, foam suppressing, and deaerating.

● Automotive holds the largest share in the defoaming coating additives industry.

● The rising need for efficient additives in the paints and coatings sector is a primary driver of the defoaming coating additives market.

● The defoaming coating additives market growth and forecast highlight a significant rise due to innovation in formulation development and the growing emphasis on eco-friendly alternatives.

Industry Trends and Drivers:

● Growing demand from the paints and coatings industry:

The increasing demand in the paints and coatings industry is one of the major factors boosting the defoaming coating additives market share. These additives are vital in preventing foam formation during the production and application of paints, which can lead to surface defects and poor finish quality. As the construction and automotive industries continue to expand, particularly in emerging markets, the demand for high-quality paints and coatings is rising. Defoaming additives help ensure smoother applications and improve overall product performance by eliminating bubbles and enhancing the surface appearance. The ongoing urbanization and industrial development worldwide are further contributing to the growing demand for paints, directly influencing the market for defoaming additives.

● Rising need for high-performance industrial coatings:

The defoaming coating additives market trends indicate that the increasing demand for high-performance industrial coatings is contributing substantially to market growth. Industrial applications, such as machinery, pipelines, and heavy equipment, require durable coatings that can withstand harsh environments. The formation of foam during the coating process can compromise the integrity of the protective layer, making defoaming additives essential for maintaining coating quality. Consequently, industries are seeking more robust coatings to enhance corrosion resistance, improve durability, and reduce maintenance costs, boosting the defoaming coating additives demand. These additives help improve the performance of industrial coatings by ensuring a smooth, defect-free finish, contributing to the longevity and effectiveness of protective coatings in demanding environments.

● Technological advancements in coating formulations:

Technological advancements in coating formulations are significantly influencing the growth of the defoaming coating additives market. As manufacturers strive to improve the efficiency and effectiveness of coatings, the development of innovative defoaming additives has become essential. Modern defoamers are designed to be more compatible with various coating systems, offering improved stability, longer-lasting performance, and enhanced environmental friendliness. Moreover, the shift toward water-based coatings, driven by environmental regulations and the need for more sustainable solutions, has created new challenges in foam control. This is increasing the demand for specialized additives, thereby driving the defoaming coating additives market size. These advancements improve the overall quality of coatings and also help manufacturers meet regulatory requirements for various environmental standards, facilitating overall industry expansion.

For an in-depth analysis, you can request a sample copy of the report: https://www.imarcgroup.com/defoaming-coating-additives-market/requestsample

Defoaming Coating Additives Market Report Segmentation:

Breakup By Product Type:

● Water-based Systems

○ Silicone

○ Emulsion

○ Polymer

○ Powder

○ Others

● Solvent-based Systems

○ Polymer

○ Silicone

Water-based systems, including silicone, account for the majority of shares due to their eco-friendly nature, as they emit lower volatile organic compounds (VOCs) compared to solvent-based alternatives.

Breakup By Function:

● Foam Breaking

● Foam Suppressing

● Deaerating

Based on the function, the market has been segregated into foam breaking, foam suppressing, and deaerating.

Breakup By End Use Industry:

● Building and Construction

● Automotive

● Wood and Furniture

● Others

Automotive represents the majority of shares due to the need for smooth, blemish-free finishes on vehicles.

Breakup By Region:

● North America (United States, Canada)

● Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

● Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

● Latin America (Brazil, Mexico, Others)

● Middle East and Africa

Asia Pacific holds the leading position owing to a large market for defoaming coating additives driven by rapid industrialization, expanding construction activities, and a booming automotive sector in countries such as China and India.

Top Defoaming Coating Additives Market Leaders:

● Air Products and Chemicals Inc.

● Altana AG

● Arkema S.A.

● Ashland Global

● BASF SE

● Clariant AG

● Dow Inc.

● Elementis PLC

● Elkem ASA (China National Bluestar (Group) Co. Ltd.)

● Evonik Industries AG

● Kemira Oyj

● Momentive Performance Materials Inc.

● Solvay S.A.

● Wacker Chemie AG

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.