Milling machines are indispensable tools in various industries, from manufacturing to prototyping. Understanding the different parts of a milling machine and their functions is crucial for operating the machine efficiently and achieving precise results. In this guide, we will explore the key milling machine parts and delve into their roles in the machining process.

Base: The base of a milling machine parts provides stability and support for all other components. Typically made of cast iron, the base is heavy and rigid to minimize vibrations during operation. It is essential for maintaining accuracy in machining.

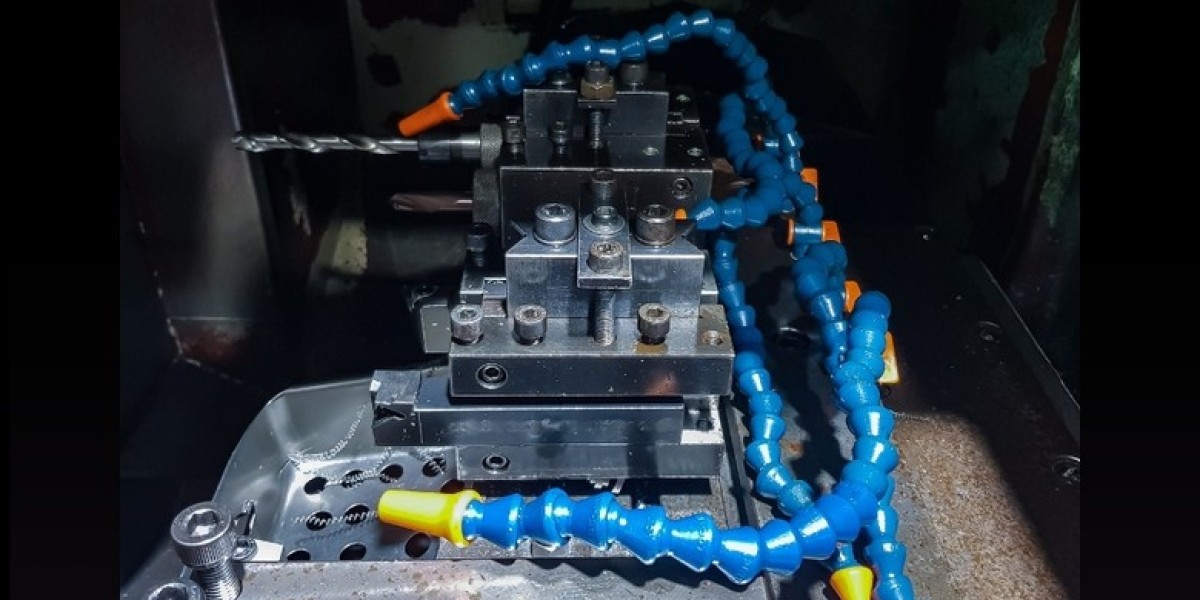

Column: Mounted on the base, the column houses the spindle assembly and other moving parts of the milling machine parts. It provides vertical support and allows for height adjustment of the spindle. The column is often equipped with dovetail or box ways for smooth movement of the saddle and table.

Spindle: The spindle is the heart of the milling machine parts, responsible for rotating the cutting tool. It can be driven by various means, such as belts, gears, or direct drive motors. The spindle speed and direction can be controlled to accommodate different materials and cutting operations.

Saddle: The saddle is mounted on the column and can move along the length of the bed, providing horizontal movement to the workpiece. It supports the table and allows for precise positioning of the workpiece under the cutting tool.

Table: The table is where the workpiece is secured during machining. It can move in both longitudinal (X-axis) and transverse (Y-axis) directions, as well as vertically (Z-axis) in some machines. The table may have T-slots for attaching workholding devices such as vises and clamps.

Knee: The knee is a vertically adjustable component located between the saddle and the table. It allows for fine adjustment of the vertical position of the workpiece and cutting tool. The knee is especially useful for making depth adjustments during milling operations.

Quill: Some milling machines feature a quill, which is a vertical spindle extension attached to the spindle housing. The quill can be lowered or raised independently of the spindle to perform drilling or boring operations. It adds versatility to the milling machine by enabling both milling and drilling in one setup.

Feed Mechanism: The feed mechanism controls the movement of the table and saddle during machining. It may consist of handwheels, power feeds, or CNC controls, depending on the type of milling machine. Accurate feed control is essential for achieving precise cuts and surface finishes.

Coolant System: Many milling machines are equipped with a coolant system to lubricate and cool the cutting tool and workpiece during machining. Coolant helps prolong tool life, improve surface finish, and evacuate chips from the cutting zone, enhancing overall efficiency and quality of machining.

Conclusion: Mastering the various milling machine parts is fundamental for anyone involved in machining operations. Each component plays a crucial role in the milling process, contributing to the machine's accuracy, versatility, and efficiency. By understanding how these parts work together, operators can harness the full potential of milling machines to produce high-quality machined parts.