Steel is the backbone of modern construction, playing a critical role in the strength and stability of buildings, bridges, industrial facilities, and infrastructure projects. The accuracy of steel fabrication and erection depends significantly on steel detailing services, which provide detailed drawings and plans for steel components. These services ensure that every steel structure is designed and built with precision, reducing errors, minimizing material waste, and optimizing project timelines.

The Role of Steel Detailing in Construction

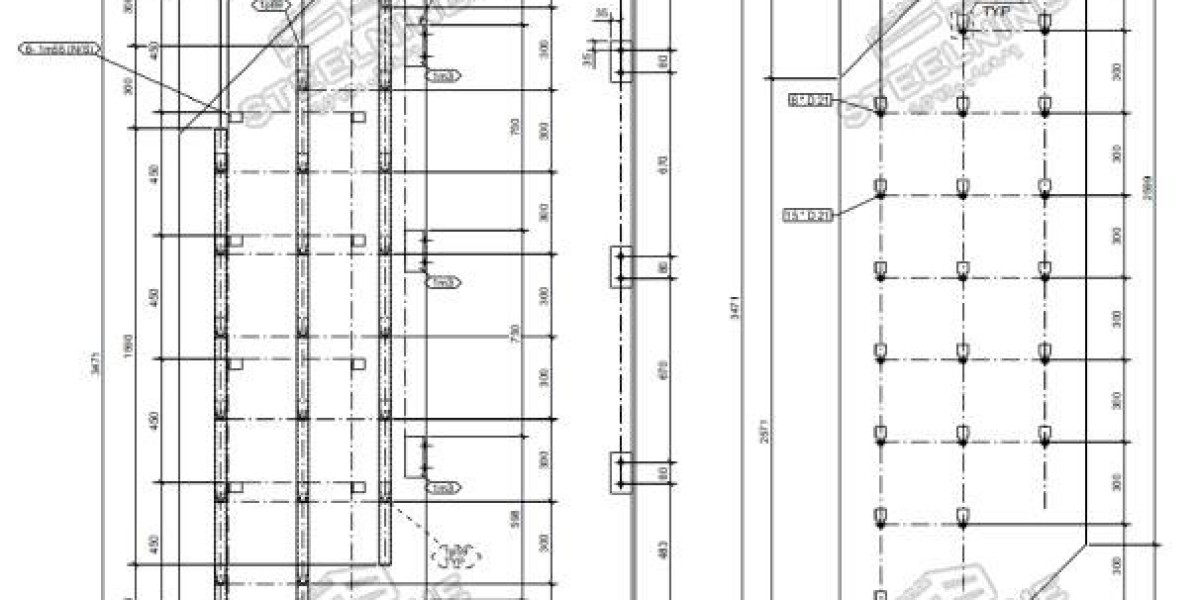

Steel detailing serves as the link between engineering design and actual construction. It involves the creation of detailed drawings, models, and reports that guide fabricators and erectors in assembling steel structures. These drawings include key information such as material specifications, dimensions, welding details, and bolt placements. Modern steel detailing relies heavily on advanced software like Tekla Structures, AutoCAD, and SDS/2, which enable 3D modeling and automated clash detection, ensuring seamless coordination between architects, engineers, and fabricators.

Why Steel Detailing Services Are Essential

With the growing demand for complex and large-scale construction projects, the importance of steel detailing services cannot be overstated. These services offer a range of benefits that contribute to the success of a project:

Accuracy and Precision: Detailed shop drawings and erection plans eliminate discrepancies, reducing costly rework and construction delays.

Cost Efficiency: Proper detailing minimizes material waste, optimizes fabrication, and enhances project budgeting.

Enhanced Collaboration: Clear communication between stakeholders, including architects, engineers, and contractors, is facilitated through well-prepared steel detailing documentation.

Improved Structural Integrity: Accurate detailing ensures that steel structures comply with safety and design standards, reducing the risk of structural failures.

Faster Project Completion: Streamlined fabrication and erection processes help in meeting tight construction deadlines.

The Process of Steel Detailing

The steel detailing process involves several key steps that ensure seamless execution from design to construction:

Understanding Project Requirements: The steel detailing team reviews structural and architectural plans to understand design specifications.

Modeling and Drafting: Using 3D modeling software, detailed shop drawings and erection plans are created.

Clash Detection and Coordination: Advanced tools identify potential conflicts before construction begins, allowing for corrections in the design phase.

Approval and Revisions: Drawings are reviewed and approved by engineers before they are sent to fabricators.

Fabrication and Erection Support: Once approved, fabricators use these drawings to cut, weld, and assemble steel components, ensuring accuracy during construction.

Technologies Used in Steel Detailing

Steel detailing has evolved significantly with technological advancements. Some of the most commonly used software tools include:

Tekla Structures: Widely used for 3D modeling and generating highly accurate steel detailing drawings.

AutoCAD: Helps create precise 2D and 3D detailing plans for structural projects.

SDS/2: Used for automated steel detailing and connection design.

Revit: Supports BIM integration, ensuring seamless collaboration between various project stakeholders.

Common Applications of Steel Detailing Services

Steel detailing services are crucial in various sectors, including:

Commercial Buildings: High-rise office buildings, shopping centers, and mixed-use developments rely on precise detailing for structural stability.

Industrial Facilities: Manufacturing plants, warehouses, and processing units require detailed steel frameworks to support heavy machinery.

Infrastructure Projects: Bridges, tunnels, and railway stations need robust steel detailing for longevity and durability.

Residential Structures: Modern residential buildings incorporate steel framing to enhance design flexibility and strength.

Challenges in Steel Detailing and How to Overcome Them

Despite its benefits, steel detailing presents several challenges:

Complexity in Design: Large-scale projects involve intricate designs, making detailing challenging. Solution: Advanced 3D modeling tools help streamline the detailing process.

Coordination Issues: Multiple teams working on a project can lead to miscommunication. Solution: BIM integration ensures real-time collaboration among stakeholders.

Tight Deadlines: Fast-paced construction schedules put pressure on steel detailing teams. Solution: Automated detailing software accelerates the drafting process, improving efficiency.

Choosing the Right Steel Detailing Partner

Selecting a reliable steel detailing service provider is crucial for the success of your project. Key factors to consider include:

Expertise and Experience: Look for a provider with a strong portfolio in structural detailing.

Technology Adoption: Ensure they use the latest software and tools for precise detailing.

Compliance with Industry Standards: The provider should adhere to AISC, NISD, and other relevant industry codes.

Timely Delivery: A reliable team should meet project deadlines without compromising quality.

Conclusion

Steel detailing services are a fundamental aspect of modern construction, ensuring accuracy, efficiency, and cost-effectiveness in steel fabrication and erection. With advancements in technology and software, steel detailing continues to evolve, offering greater precision and collaboration across construction projects. Whether for commercial buildings, infrastructure, or industrial facilities, investing in professional steel detailing services enhances project success and structural integrity.