Concrete forms the backbone of countless construction projects, from residential driveways to massive bridges and skyscrapers. When it comes to reinforcement, steel fiber reinforced concrete vs rebar is a critical choice for any builder or project manager. Understanding the composition, benefits, and potential drawbacks of each method helps you make an informed decision. In this article, we’ll explore both options in depth, looking at their strength, durability, cost considerations, and environmental impact. Whether you’re planning a small-scale renovation or a large commercial development, this guide will shed light on which reinforcement method suits your project best.

Understanding Steel Fiber Reinforced Concrete

Composition and Key Benefits

Steel fiber reinforced concrete (SFRC) is created by uniformly mixing discrete steel fibers into the concrete matrix. These steel fibers can range in shape—such as hooked, crimped, or straight—and typically measure between 25 to 60 millimeters in length. The fibers distribute throughout the concrete, forming a network that helps control cracking and increases tensile strength.

Key Benefits

- Enhanced Crack Resistance: The interconnected steel fibers help reduce crack propagation and improve ductility.

- Even Stress Distribution: Compared to isolated reinforcement bars, fibers disperse stress throughout the concrete matrix.

- Reduced Need for Additional Reinforcement: In some applications, SFRC may eliminate or reduce the need for secondary rebar.

- Faster Construction: Because fibers are mixed in during batching, there’s no separate step for placing and tying rebar.

A 2020 report by the American Concrete Institute (ACI) mentions that steel fiber reinforcement can improve the post-cracking strength of concrete by up to 40% in certain applications, highlighting its potential for superior performance in specific scenarios.

Real-World Applications

SFRC is used extensively in industrial floors, airport pavements, tunneling, and precast concrete elements. These environments benefit from SFRC’s ability to resist heavy impacts and dynamic loads.

- Industrial Floors: Distributing steel fibers within the concrete slab helps withstand point loads from machinery or forklift traffic.

- Tunnels and Mining: The reduced crack width and enhanced toughness make SFRC a strong candidate for lining tunnels.

- Precast Components: Adding steel fibers can lower the need for rebar cages in some precast concrete products, speeding up manufacturing.

Rebar Basics

Composition and Key Benefits

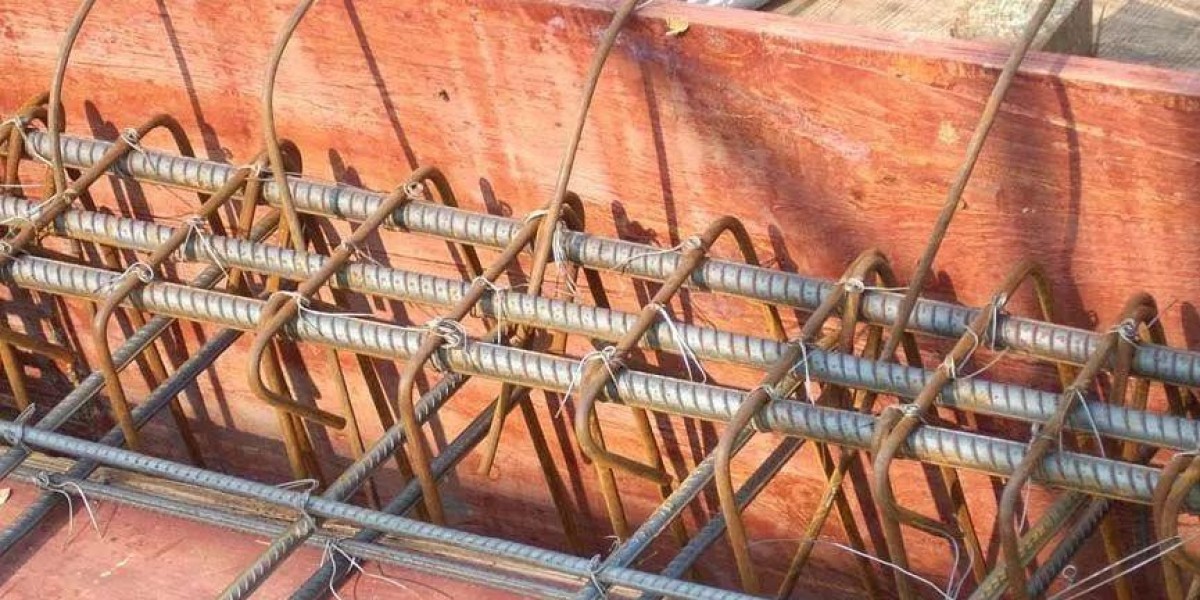

Rebar, short for “reinforcing bar,” is typically made of carbon steel. These bars are embedded within concrete to provide tensile strength where the material would otherwise be weakest. Rebar has ridges or deformations on its surface to form a better bond with the concrete.

Key Benefits

- Proven Track Record: Rebar has been used for decades and is familiar to engineers, contractors, and inspectors.

- High Tensile Strength: Steel bars significantly bolster concrete’s load-bearing capacity, particularly in bending and tension.

- Easily Customized: Rebar can be cut, shaped, and welded to fit design specifications, ensuring targeted reinforcement where needed.

Typical Use Cases

Rebar remains the default choice for a wide range of construction projects.

- Foundations and Footings: Rebar is crucial for withstanding compressive loads from the structure above.

- Columns and Beams: Reinforcing bars provide the tensile reinforcement necessary to handle bending moments.

- Roadways and Bridges: Large infrastructure projects require significant steel reinforcement to maintain structural integrity over time.

Comparing Strength and Durability

Tensile and Flexural Strength

- Steel Fiber Reinforced Concrete: The fibers enhance tensile and flexural strength by preventing cracks from widening. This can lead to better overall structural integrity under dynamic or impact loads.

- Rebar: Traditional steel bars excel at handling tensile forces, especially in flexural elements like beams and slabs. However, rebar reinforcement is localized to specific areas rather than being spread uniformly.

Longevity and Maintenance

- SFRC: By minimizing crack formation, SFRC can reduce the likelihood of water seepage, corrosion, and freeze-thaw damage. Still, quality control in mixing and fiber dosage is crucial for consistent performance.

- Rebar: Properly placed and protected rebar can last for decades. However, if water or chlorides reach the steel surface, corrosion may occur, leading to spalling or other structural issues. Routine inspections and timely repairs are recommended for long-term durability.

Construction and Cost Considerations

Material Costs

- Steel Fiber Reinforced Concrete: Upfront costs may be higher due to the price of steel fibers, which can vary depending on quality and type. However, the reduced need for additional reinforcement and faster installation could offset these expenses.

- Rebar: Conventional rebar is more affordable on a per-pound basis, but larger or complex rebar arrangements can drive up labor costs.

Installation and Labor

- SFRC: Mixing fibers into concrete requires precision. Once the correct proportions are determined, the placement is often quicker because you don’t need separate reinforcement layers.

- Rebar: Installation involves cutting, bending, tying, or welding bars, which can be time-consuming. On complex projects, rebar detailing and placement become more complicated, potentially increasing labor expenses.

Environmental Impact

Sustainability Factors

- SFRC: Since steel fibers can be made from recycled materials, some builders consider SFRC a more sustainable choice. Fewer reinforcement bars also mean less steel consumption overall in certain projects.

- Rebar: Most steel reinforcing bars can contain recycled content, but the overall steel requirement may be higher compared to steel fiber solutions, depending on the project’s design.

Life Cycle Assessment

- Steel Fiber Reinforced Concrete: Enhanced crack resistance could extend a structure’s lifespan, reducing the need for future repairs and material usage.

- Rebar: Rebar-based construction often has a well-understood maintenance cycle. While corrosion protection methods have improved, repeated repairs or retrofits can add to the environmental burden over a building’s lifetime.

Conclusion

When comparing steel fiber reinforced concrete vs rebar, there’s no one-size-fits-all answer. SFRC offers enhanced crack control and faster installation, making it ideal for heavy-duty floors, pavements, or structures exposed to dynamic loads. On the other hand, rebar remains a proven, widely understood method with high tensile strength that’s well-suited for traditional beams, columns, and foundations.

Your best choice depends on factors like project size, budget, local building codes, and environmental conditions. If your application could benefit from uniform reinforcement and rapid placement, steel fibers are worth exploring. However, if you need precise reinforcement in key tension zones or are working with well-established structural designs, sticking with rebar may be the safer bet.

Call to Action

Have you tried steel fiber reinforced concrete in your projects, or do you prefer rebar? Share your experiences in the comments and subscribe to our newsletter for more in-depth construction insights. Your feedback could help others make the right choice for their next build!