1. Robotics in Casting Processes

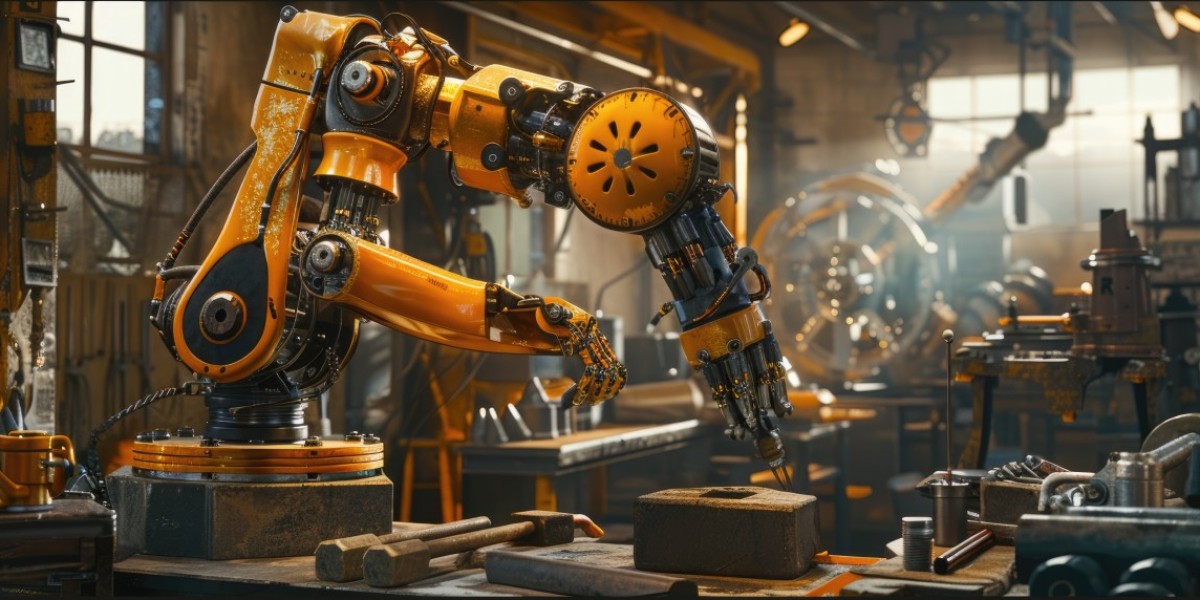

Robotic systems are optimizing critical casting tasks, including mold preparation, molten metal pouring, and product handling. These innovations ensure precision, consistency, and reduced operational risks.

Equipped with specialized tools, robotic arms perform intricate tasks such as molten metal pouring with exceptional accuracy, ensuring uniform product quality while minimizing worker exposure to extreme heat and hazardous conditions. Industry leaders like FANUC provide state-of-the-art robotic solutions designed for mold handling and metal pouring.

Additionally, automated monitoring systems integrated with robotics allow real-time adjustments, ensuring adherence to strict quality standards. Learn more about Leister Technologies' Projects in Foundry Automation and their role in optimizing casting operations.

2. Robotics in Material Handling

Efficient material transport is crucial in foundry operations, and robotics has significantly enhanced safety and workflow optimization. Traditional handling of heavy and hot materials posed substantial risks to workers, but robotic transport systems and autonomous guided vehicles (AGVs) have revolutionized this aspect of production.

Companies such as KUKA and ABB have engineered robotic transport solutions capable of withstanding extreme conditions, ensuring efficient material movement and reducing production downtime. Discover Leister Technologies' Innovations in Material Handling and how automation is streamlining foundry logistics.

3. Robotics in Quality Control and Inspection

Quality assurance is a critical component of foundry operations, and robotics is leading advancements in precision and efficiency. Automated inspection systems equipped with high-resolution imaging and sensor technology can detect defects faster and more accurately than manual methods.

For instance, Creaform’s robotic inspection solutions use non-destructive testing techniques to identify defects early in the production process, reducing waste and improving product consistency. Explore Leister Technologies' Approach to Automated Quality Control to see how robotics is enhancing quality assurance.

4. Improving Workplace Safety with Robotics

Robotics has significantly improved workplace safety in foundries by automating high-risk tasks. Manual handling of heavy materials and exposure to extreme temperatures present serious hazards, but robotic solutions effectively mitigate these dangers.

Modern robotic systems incorporate built-in safety features such as emergency stop functions and collision detection, ensuring a secure work environment. By reducing workplace injuries, companies can foster a safer and more productive workforce.

5. The Future of Robotics in Foundries

As robotics technology continues to evolve, foundry operations are becoming increasingly automated and intelligent. Advances in artificial intelligence (AI) and machine learning are enabling robots to adapt to dynamic conditions, further optimizing efficiency and flexibility.

AI-powered predictive maintenance allows robotic systems to receive proactive servicing, reducing downtime and improving operational reliability. Additionally, collaborative robots (cobots) are bridging the gap between human labor and full automation, fostering an efficient and adaptive workforce.

Conclusion

Robotics is revolutionizing the foundry industry by automating key processes, enhancing safety, and improving quality control. From casting to material handling, robotic solutions are paving the way for greater efficiency and productivity. As technology advances, robotics will continue unlocking new possibilities in foundry automation.

To explore how robotics is shaping the future of manufacturing, visit Leister Technologies and discover their cutting-edge projects and solutions.