The convenience of online shopping is undeniable, yet it comes with hidden dangers. Websites like ultimateshop.ru raise serious concerns because of their association with dumps and CVV2 shops. These platforms thrive in the underground digital economy, where stolen data becomes a product for sale.

Dumps are collections of stolen credit card data harvested from compromised systems, while CVV2 shops specialize in reselling sensitive card security codes. Sites like ultimateshop.ru bring these elements together, creating a hub for illegal trading disguised as ordinary online services. Shoppers unaware of these connections may unknowingly place themselves at risk.

The dangers are not abstract—they are personal and immediate. Victims of stolen financial data often face sudden unauthorized charges, drained accounts, and weeks of stress trying to recover funds. Even when banks refund money, the anxiety of knowing your data is out there is difficult to overcome.

Identity theft is another long-term consequence. With enough information, criminals can apply for credit, loans, or services under a victim’s name. The damage to one’s financial reputation can last years, requiring persistent effort to repair. For anyone considering ultimateshop.ru, the risks far exceed any perceived advantages.

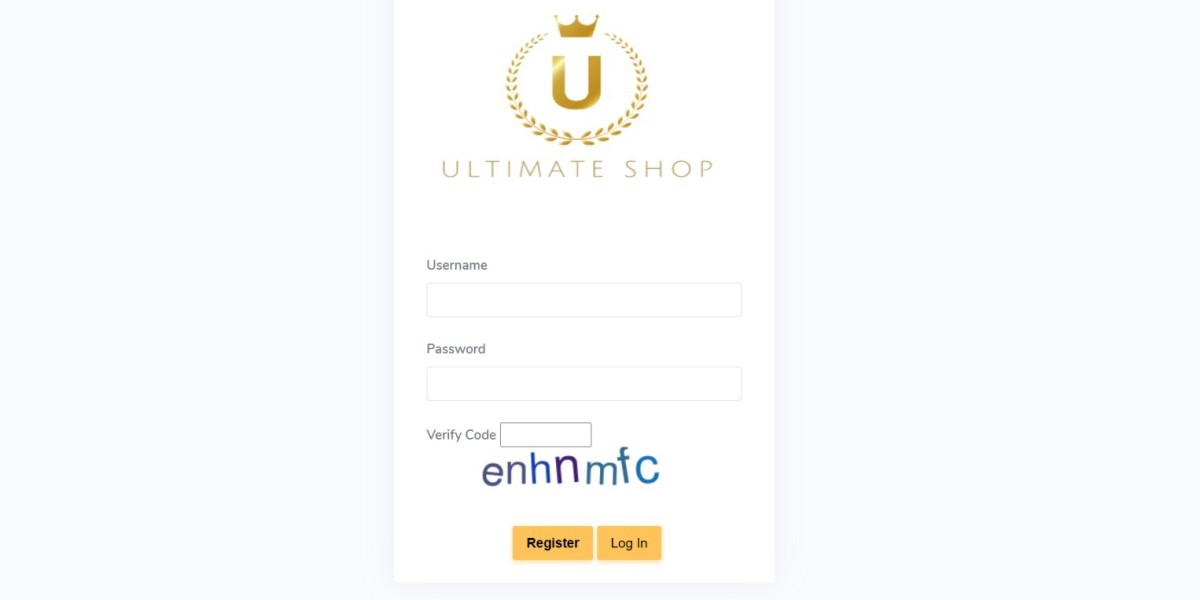

Malware is another weapon such sites use. Cybercriminals may embed malicious software within downloads or fake login prompts. Once a device is infected, attackers gain access to personal files, financial accounts, and even private communications. What begins as a simple visit can escalate into a serious breach of privacy.

Another crucial point is legality. Engaging with sites tied to dumps and CVV2 shops is not just unsafe—it is illegal. Authorities constantly monitor digital marketplaces for criminal activity. Even browsing such platforms can lead to suspicion, investigations, and consequences that no shopper wants to face.

Consumers can protect themselves by practicing safer online habits. Always verify the legitimacy of a website before making purchases. Stick to reputable online stores that use secure payment systems with encryption. Avoid entering sensitive card details on unfamiliar platforms and consider safer alternatives like virtual cards or digital wallets.

Regularly checking bank accounts and credit reports can also help detect fraud early. Additionally, keeping devices updated with the latest security software significantly lowers the risk of falling victim to malware. Education is the best tool—being aware of how sites like ultimateshop.ru operate gives individuals the power to avoid them.

Ultimately, ultimateshop.ru highlights the darker side of online shopping. Its links to dumps and CVV2 shops underline the risks of financial loss, identity theft, and legal trouble. In today’s world, awareness and caution are the best shields against cybercrime. Shoppers must prioritize safety, choosing trusted platforms over suspicious ones to protect their digital and financial wellbeing.