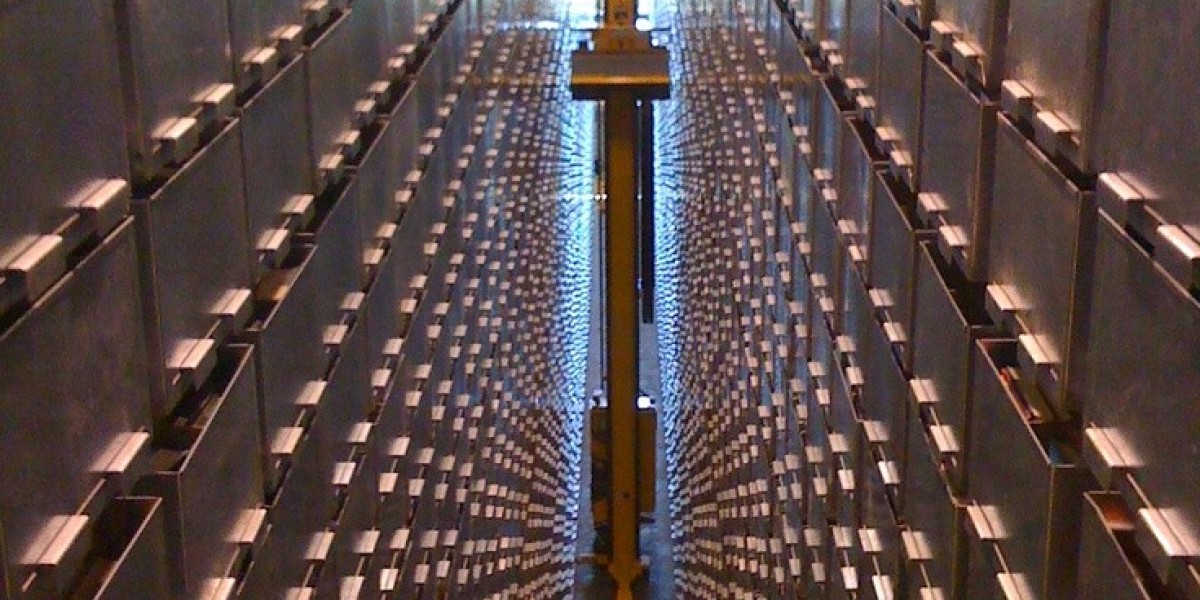

The global Automated Storage and Retrieval Systems Market is undergoing rapid transformation as businesses increasingly adopt automation to optimize warehouse operations, reduce costs, and enhance supply chain resilience. With e-commerce expansion, labor shortages, and the demand for faster order fulfillment, automated systems are becoming essential for companies seeking to stay competitive. Emerging technologies such as AI-driven robotics, IoT-enabled monitoring, and digital twin modeling are further accelerating adoption. This article explores the most significant trends shaping the market and their implications across industries.

1. Rising Adoption Across E-commerce and Retail

One of the most prominent drivers of ASRS growth is the surge in e-commerce. Online retailers face continuous pressure to provide faster delivery times while managing diverse product categories and fluctuating demand. Automated storage and retrieval systems allow them to optimize inventory placement, improve order picking accuracy, and reduce delivery lead times. In addition, omnichannel retailers are integrating ASRS to handle both bulk distribution to stores and direct-to-consumer shipments, ensuring seamless operations across multiple channels.

2. Integration of AI and Machine Learning

Artificial intelligence and machine learning are playing a vital role in making ASRS more intelligent and adaptive. AI-driven systems can analyze inventory patterns, forecast demand, and automatically adjust storage allocation for improved efficiency. Machine learning algorithms help predict peak demand periods, optimize space utilization, and even enable predictive maintenance of automated equipment. This trend not only reduces downtime but also significantly enhances throughput and cost efficiency in warehouses and manufacturing facilities.

3. Energy-Efficient and Sustainable Solutions

Sustainability has become a central focus for industries worldwide. Modern ASRS designs are increasingly incorporating energy-efficient components, regenerative braking systems, and lightweight construction materials to reduce environmental impact. Additionally, ASRS helps companies minimize their physical footprint by using vertical storage solutions, which conserve floor space and reduce the need for large warehouses. This shift towards green logistics not only aligns with corporate sustainability goals but also lowers operational expenses over the long term.

4. Growth in Cold Storage and Food Logistics

The food and beverage sector is witnessing rising demand for ASRS, particularly in cold storage environments. Automated systems ensure precise temperature control, minimize human exposure to extreme conditions, and reduce product spoilage. With global demand for frozen and packaged foods growing, companies are investing heavily in automated cold storage facilities. These solutions are also vital for the pharmaceutical industry, especially in maintaining the integrity of temperature-sensitive products like vaccines and biologics.

5. Increasing Role of IoT and Digital Twins

IoT-enabled ASRS solutions are gaining traction as businesses seek real-time visibility and control over operations. Sensors and connected devices monitor system performance, track inventory movement, and identify potential inefficiencies. Digital twin technology is also emerging as a key enabler, allowing companies to create virtual models of warehouse operations. This makes it possible to test various layouts, simulate peak demand scenarios, and optimize system performance without disrupting actual operations.

6. Modular and Scalable System Designs

Flexibility is becoming a major requirement for companies investing in automation. Many businesses now prefer modular ASRS designs that can be scaled up or reconfigured as their operations grow. Whether expanding storage capacity or adapting to new product lines, modular systems offer cost-effective and future-ready solutions. This trend is particularly beneficial for small and medium-sized enterprises (SMEs) that need automation but want to avoid the risk of over-investing in rigid, large-scale systems.

7. Labor Shortages Driving Automation

Global labor shortages, particularly in logistics and warehousing, are accelerating the adoption of ASRS. High turnover rates, increasing wages, and the difficulty of finding skilled workers make automation a practical solution. ASRS reduces reliance on manual labor for repetitive tasks while reallocating workers to value-added roles such as system oversight and customer service. By addressing workforce challenges, automation helps businesses maintain productivity and operational continuity.

8. Expanding Applications Beyond Warehousing

Although ASRS is most commonly associated with warehousing and distribution, its applications are expanding into sectors such as automotive, healthcare, aerospace, and electronics. Manufacturers are using ASRS for component storage, assembly line feeding, and just-in-time delivery of parts. Hospitals and laboratories employ ASRS for managing pharmaceuticals, medical supplies, and research samples, ensuring accuracy, traceability, and security. These diverse applications underscore the versatility and growing relevance of automated storage solutions.

Conclusion

The Automated Storage and Retrieval Systems market is being reshaped by a combination of technology-driven advancements, industry-specific requirements, and macroeconomic challenges such as labor shortages and sustainability goals. Companies across sectors are turning to ASRS to enhance operational efficiency, improve order fulfillment, and remain competitive in a fast-changing global economy. As AI, IoT, and modular designs continue to evolve, the market is poised for sustained growth, unlocking new opportunities in logistics, manufacturing, and beyond.