From drainage systems and drainage pipes to chemical storage tanks and tunnels, concrete, despite its underlying strength, is exposed to the fall. This decline can manifest cracks, cleavage and even complete structural failure, leading to expensive repairs, environmental hazards and shutdowns. Go into the HDPE R-rib liner sheets a strong and easy solution designed to provide unique safety, significantly increases the service life and increases the performance of significant concrete infrastructure. These special sheets prepared from high density polyethylene provide a better barrier to rust, friction and chemical attacks, making them an indispensable property in modern design and rehabilitation projects.

The Genesis of Durability: Understanding HDPE

This material claims an impressive selection of properties that make it ideal for demanding applications. In addition, HDPE has a remarkable power force, which makes it flexible against physical damage and puncture. The low permeability ensures that aggressive substances cannot enter through the lining to reach the concrete substrate. It is important that HDPE is also mild, which makes it easy to handle and installed, and it is non-toxic, making it suitable for applications associated with drinking water and food products. These underlying properties of HDPE form the basis for excellent protective functions provided by HDPE T-RB lining.

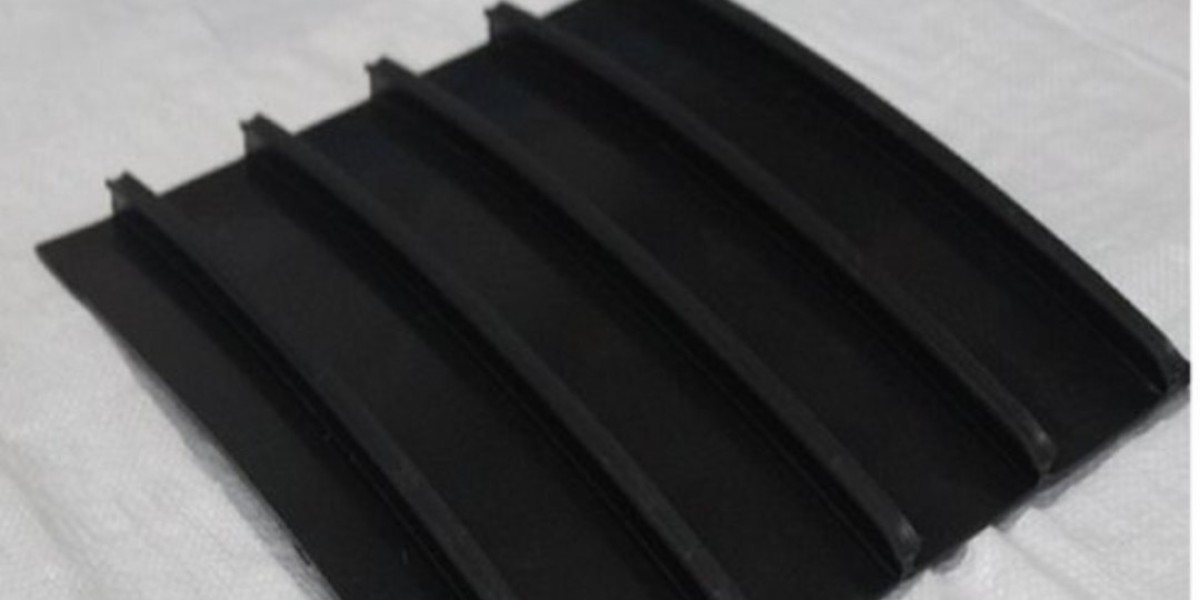

The Ingenious Design: T-Ribs for Enhanced Anchorage

In addition to the traditional lining material, what sets the HDPE t rib liner manufacturer is their unique profile. These ribs perform an important function: to provide a mechanical anchor in the concrete. During the concrete insert process, the wet concrete flows around and meets these ribs, causing an incredibly strong, unbroken bond between the lining and the concrete. This mechanical interlock ensures that the lining remains strong during considerable hydrostatic pressure, temperature races and downs. Unlike glue-based lining systems, which can delimitate due to failure of the bond over time, the T-rib design provides almost inseparable connections, and guarantees long-lasting integrity and performance. This strong meeting system is an important discrimination and provides better resistance to regeneration and ensuring long life.

Applications Across Industries

The versatility and better protective properties of the HDPE T-rib lining sheet make them suitable for a large selection of applications in many industries. In the wastewater sector, they are used to set up sewage collection systems, manhole, lifting stations and wastewater treatment tanks, safety against corrosive effects of hydrogen sulfide gas and protect against other aggressive chemicals in drains. For chemical processing plants, these lining provides invaluable protection for container structures, prevents hazardous chemical leaks and ensures compliance with environmental rules. Tunnels, culverts and other underground structures are also very favorable for HDPE T-rib lining, as they provide an impenetrable barrier to groundwater input and soil pollution. Printable water reservoirs and pipelines are another important application, where non-types of HDPE and low parameter nature ensure the purity of drinking water. Demand for a reliable HDPE T-rib liner producer has increased due to the increasing recognition of the benefits of these sheets.

Installation Methodology: A Seamless Process

The installation of MAHIRA POLYGLOBAL LLP is a well-established process, which, if performed correctly, ensures optimal performance. The sheets are usually pre -produced for specific dimensions and can easily be cut and welded on site to create a constant, impenetrable membrane. While inserting concrete, the ribbed side of the sheet is distributed to the shape work so that fresh concrete can surround the ribs. Welding of individual sheets is paid special attention, which uses extra welding or welding techniques for warm wall to make strong, leak -proof seams. This careful approach to installation, combined with the inherent properties of the material and unique T-rib design, ends in a very efficient and long-lasting solid safety system. The selection of a recognized HDPE T RIB supplier is important to ensure the quality of the material and the success of installation.

Conclusion

Their unique design creates a unique barrier to the most aggressive environment, combined with the underlying durability of HDPE t rib liner and chemical resistance. From reducing war in wastewater systems to protecting chemical control systems, this lining shows to be an indispensable property for engineers and project managers worldwide. Their installation, long service life and simple financial benefits strengthen their position because the preferred option to ensure life and integrity of the infrastructure into significant concrete. Investing in HDPE T-rib lining is not just an expense; This is a strategic investment in flexibility and stability in the future of our created environment.

Frequently Asked Questions

Question: How does HDPE T-rib lining stitching prevent chemical erosion of concrete?

A: HDPE T-RB Lining sheets are made of high density polyethylene, which is naturally resistant to a wide range of chemicals, including acids, alkalis and solvents. This chemical resistance prevents aggressive substances from coming into direct contact with concrete, protecting it from corrosion, dissolution and other forms of chemical attacks.

Question: What is the special life of HDPE T-rib lining?

A: HDPE T-rib lining has an exceptionally longer life, often more than 50 years, and in many cases can last longer than a century depending on specific applications and environmental conditions. Their strong mechanical anchor and underlying resistance to falls contribute to their remarkable durability and extended lifetime.

Question: Who is the largest manufacturer of HDPE T-Rib Liner Sheets?

A: While several companies manufacture HDPE T-Rib Liner Sheets, Mahira Polyglobal LLP is a prominent manufacturer of these sheets, known for their quality and a strong brand presence.