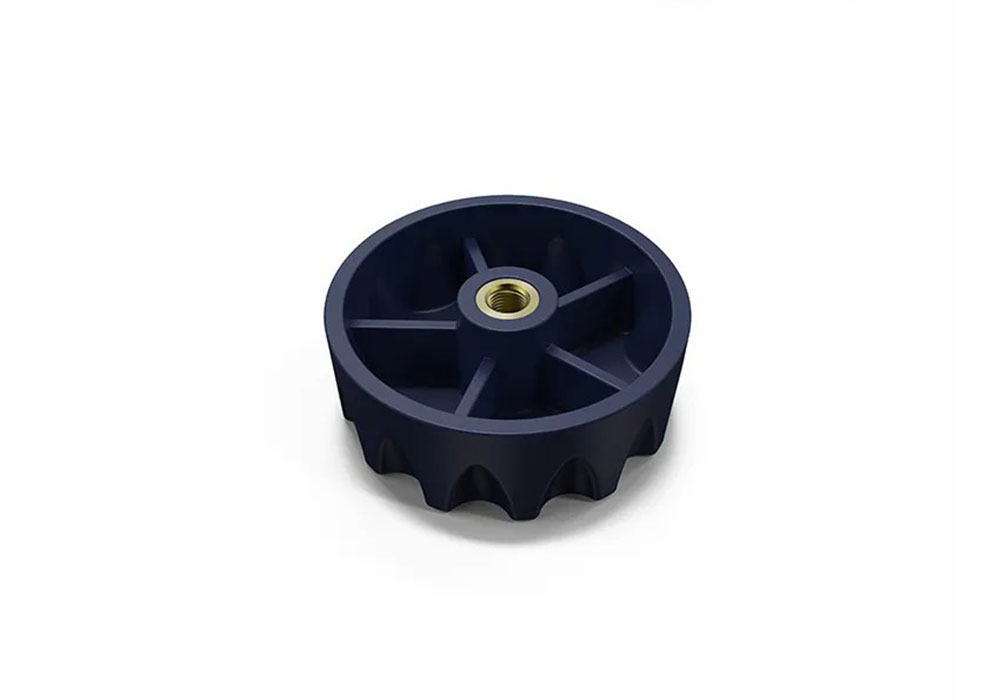

Insert molding is a process that involves the insertion of a metal, plastic, or other material into a mold before the plastic resin is injected, creating a finished product with the insert incorporated within it. This process is widely used in the manufacturing industry to produce products with enhanced functionality, durability, and aesthetics.

The Importance of Reliable Insert Molding

Reliable insert molding is crucial for achieving optimal product integration. By using precision custom insert molding services, manufacturers can ensure that the inserts are securely and accurately placed within the molded part, resulting in a seamless and integrated final product. This is especially important for products that require precise alignment, tight tolerances, and complex geometries.

Benefits of Custom Insert Molding Solutions

Custom insert molding solutions offer a range of benefits for advanced product design. One of the key advantages is the ability to combine multiple materials in a single part, enabling manufacturers to create products with unique properties and functionalities. By incorporating metal inserts into plastic parts, for example, manufacturers can achieve a balance of strength, conductivity, and weight that would be difficult to achieve with a single material.

Streamlining Production and Improving Durability

In addition, custom insert molding allows for the integration of features such as threads, fasteners, and connectors directly into the molded part, reducing the need for secondary operations and assembly processes. This not only streamlines production but also improves the overall durability and reliability of the final product.

Cost-Effective Solutions for Complex Designs

Another benefit of custom insert molding is the ability to achieve cost-effective solutions for complex designs. By combining multiple components into a single part, manufacturers can reduce the number of individual parts, assembly steps, and material waste, ultimately lowering production costs and lead times. This makes custom insert molding an attractive option for high-volume production runs and time-sensitive projects.

Design Flexibility and Versatility

Furthermore, custom insert molding offers design flexibility and versatility, allowing manufacturers to create products with intricate shapes, curves, and contours that would be difficult or impossible to achieve with traditional manufacturing methods. By using advanced molding techniques and materials, manufacturers can produce parts that meet the most demanding design requirements while maintaining the highest levels of quality and consistency.

Partnering with a Reputable Manufacturer

When seeking custom insert molding services for advanced product design, it is essential to partner with a reputable and experienced manufacturer that specializes in precision molding. By collaborating with a trusted partner, manufacturers can benefit from expertise in material selection, mold design, tooling, processing, and quality control, ensuring that every aspect of the molding process is optimized for the best results.

Conclusion

Overall, reliable insert molding is a critical component of advanced product design, offering custom solutions for optimal product integration. By leveraging the benefits of custom insert molding, manufacturers can create innovative products that not only meet but exceed the expectations of their customers in terms of functionality, aesthetics, and performance.