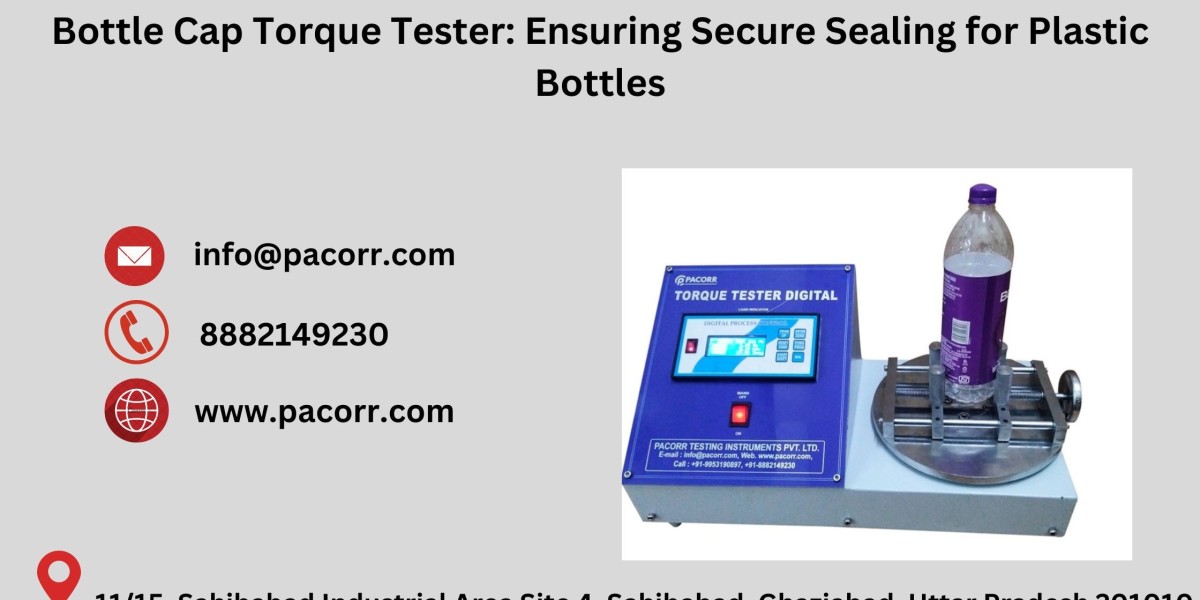

Bottle Cap Torque Tester: Ensuring Seal Integrity in the Packaging Industry

In today's packaging industry, ensuring the integrity of product seals is essential for maintaining product quality and preventing leaks or contamination. One crucial instrument used in this process is the Bottle Cap Torque Tester. This tool helps manufacturers accurately measure the torque required to open and close bottle caps, ensuring that the closure system is neither too tight nor too loose, which can lead to product failures.

Importance of Bottle Cap Torque Testing

Torque testing is essential for determining the optimal force required to secure a cap onto a bottle while ensuring it can still be easily removed by the consumer. If the torque is too high, it can result in consumers struggling to open the product, leading to frustration and potential damage to the cap or bottle. Conversely, if the torque is too low, the bottle may not seal properly, leading to leakage, contamination, or even the product spoiling.

By using a Bottle Cap Torque Tester Price, manufacturers can maintain consistency in the capping process, ensuring each product has a secure yet user-friendly seal. This consistency is crucial for maintaining brand reputation and reducing product returns due to faulty packaging.

Key Features of the Pacorr Bottle Cap Torque Tester

The Bottle Cap Torque Test from Pacorr is designed to provide accurate, repeatable, and reliable measurements. Here are some of the key features of this instrument:

- High Precision Measurements: The tester is capable of measuring both the application and removal torque with high precision, ensuring consistency in the capping process.

- Digital Display: Equipped with an easy-to-read digital display, the torque values are shown in real-time, allowing operators to make quick adjustments during production if needed.

- Adjustable Clamp: The adjustable clamp ensures that bottles of different shapes and sizes can be tested without any difficulty, making it a versatile tool for manufacturers working with a variety of products.

- Durable Build: The robust construction of the tester ensures long-term durability and reliability, making it a cost-effective investment for any production line.

- User-Friendly Interface: The simple and intuitive interface allows operators to set up tests quickly and efficiently, minimizing downtime and increasing productivity.

Applications of the Bottle Cap Torque Tester

The Bottle Cap Torque Teste is widely used in industries where the integrity of bottle seals is critical. These industries include:

- Food and Beverage: Ensuring that bottle caps are properly sealed to prevent leaks and maintain the freshness of products.

- Pharmaceuticals: Verifying that caps are securely fastened to prevent contamination or spillage of medicinal products.

- Cosmetics: Guaranteeing that cosmetic products, often contained in bottles or jars, remain sealed during transportation and storage.

- Chemical and Industrial: Testing caps on bottles containing chemicals to avoid leaks, which can be hazardous to consumers and the environment.

Benefits of Using Pacorr’s Bottle Cap Torque Tester

Using a high-quality torque tester from Pacorr offers several benefits:

- Improved Product Quality: Regular torque testing helps ensure that all products meet strict quality control standards, reducing the risk of leaks and packaging failures.

- Enhanced Consumer Satisfaction: By ensuring that bottle caps are easy to open but secure enough to prevent leaks, manufacturers can improve customer experience and satisfaction.

- Cost Efficiency: Identifying potential issues in the capping process early helps to avoid costly product recalls or returns due to packaging failures.

- Compliance with Industry Standards: Many industries have specific packaging standards, and consistent torque testing helps manufacturers meet these requirements, reducing the risk of non-compliance penalties.

Conclusion

The Bottle Cap Torque Testing plays a critical role in the packaging process, ensuring that bottles are sealed securely and that caps can be removed without excessive effort. By investing in a high-quality torque tester from Pacorr, manufacturers can improve their product quality, enhance customer satisfaction, and ensure compliance with industry standards. Whether you are in the food and beverage, pharmaceutical, or chemical industry, Pacorr’s Bottle Cap Torque Tester is an essential tool for ensuring your packaging meets the highest standards of quality and safety.