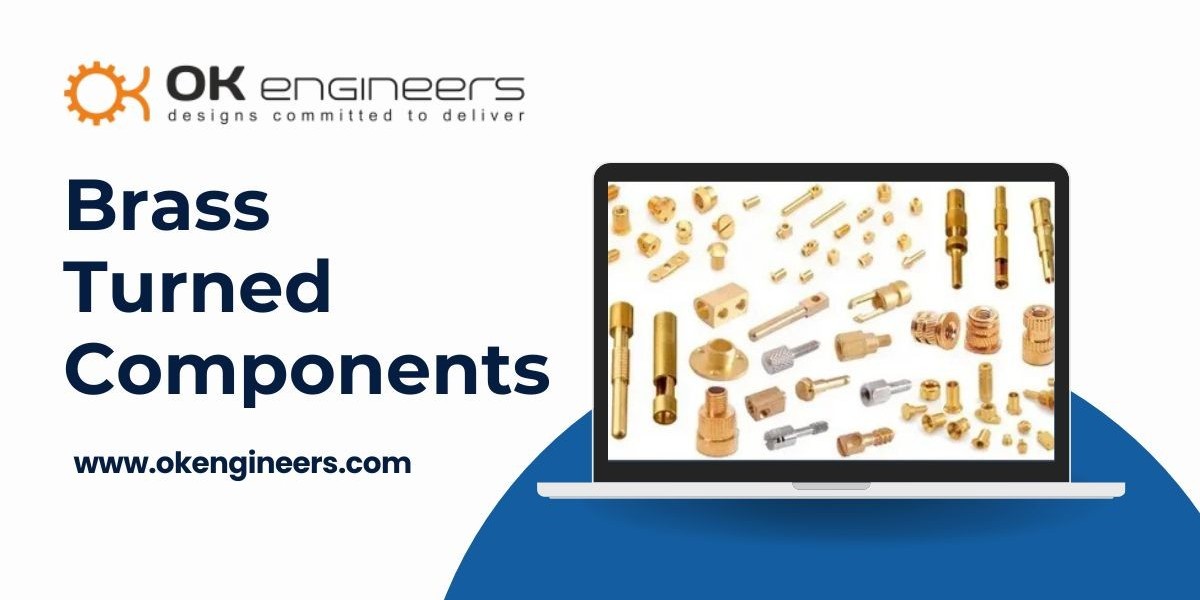

When we think of modern engineering, our minds often jump to giant machines, sleek cars, or advanced electronics. But hidden behind these marvels are tiny, precise parts that make them work flawlessly — Brass Turned Components. Manufactured with accuracy and skill, these components are the backbone of countless industries, and companies like OK Engineers are leading the way in delivering world-class solutions.

What Are Brass Turned Components?

Brass turned components are precision-engineered parts made from brass, shaped using advanced turning processes on CNC or automatic machines. They are known for their excellent strength, corrosion resistance, and ability to withstand high temperatures. Their uses range from electrical connectors to plumbing fittings, automotive parts, and instrumentation.

Why Brass is the Perfect Choice

Brass, an alloy of copper and zinc, is a favourite among engineers for several reasons:

Corrosion Resistance – Ideal for marine, plumbing, and outdoor applications.

Machinability – Easy to shape into complex designs without losing strength.

Durability – Handles wear and tear, making it perfect for long-term use.

Aesthetic Appeal – Its natural golden sheen is an added bonus for decorative uses.

Applications Across Industries

Brass Turned Components play a vital role in:

Automotive Industry – Used in engines, brake systems, and electrical assemblies.

Electrical & Electronics – Essential in connectors, terminals, and switches.

Plumbing & Sanitary – Reliable fittings for leak-proof performance.

Telecommunication – Precision connectors for seamless signal transmission.

Aerospace & Defence – High-precision parts where reliability is critical.

OK Engineers – Setting the Benchmark

When it comes to quality and innovation in Brass Turned Components, OK Engineers stands out as a trusted manufacturer. With state-of-the-art machinery, strict quality control, and a skilled workforce, they deliver components that meet global standards. Their expertise ensures every piece offers flawless performance, whether for small-scale projects or high-volume industrial needs.

Conclusion

Though they may be small in size, Brass Turned Components have a massive impact on modern engineering. From ensuring the safety of vehicles to powering advanced electronics, their role is indispensable. With industry leaders like OK Engineers, the future of precision engineering looks brighter — and more efficient — than ever.

FAQs

1. What makes brass ideal for turned components?

Its strength, corrosion resistance, and ease of machining make brass a top choice.

2. Can brass turned components be customized?

Yes, companies like OK Engineers offer fully customized solutions.

3. Are they suitable for high-pressure applications?

Absolutely, especially in plumbing and hydraulic systems.

4. Do brass components require maintenance?

Minimal — they are naturally corrosion-resistant and long-lasting.

5. Which industries rely most on brass turned parts?

Automotive, electrical, plumbing, and aerospace are key users.