Introduction to Flexible Printed Circuits in Foldable Phones

The advent of foldable phones has transformed the mobile industry, offering users a unique combination of compactness and functionality. At the heart of this innovation is the Flexible Printed Circuit (FPC), which allows for seamless folding while maintaining high performance. As the foldable phone market continues to grow, the role of flexible circuits becomes even more crucial. In this article, we will explore the importance of FPC in foldable phones, its design considerations, and the market potential in the Western world.

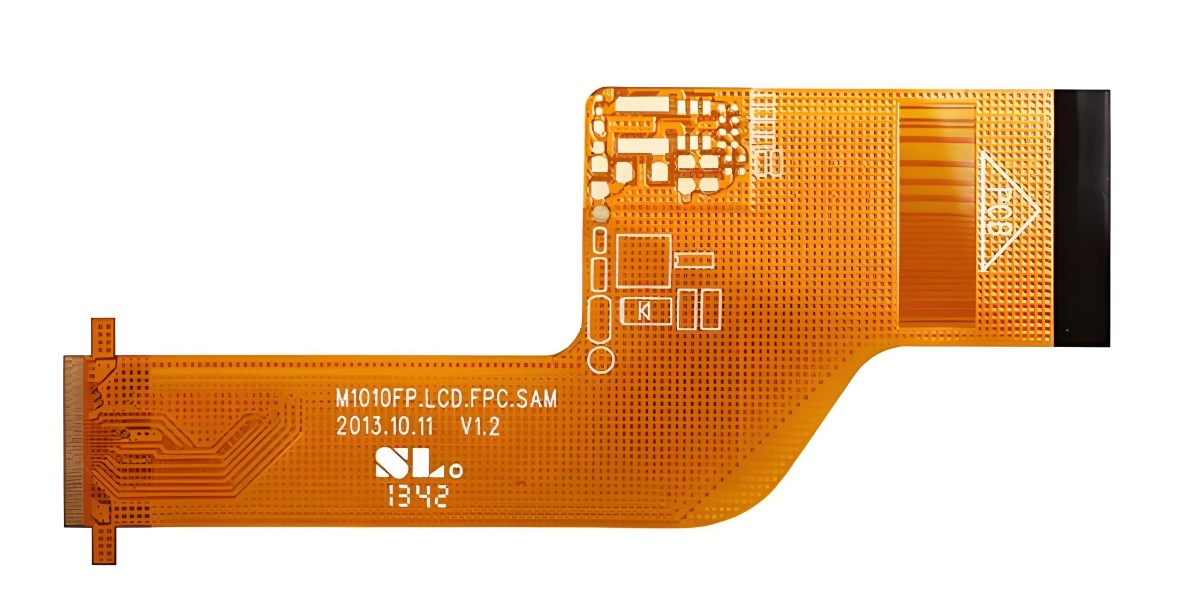

Key Features of FPC for Foldable Phones

Flexible Printed Circuits (FPC) are an integral component of foldable phones, thanks to their ability to endure repeated bending and folding without compromising electrical performance. These circuits are known for their lightweight structure, thin profile, and excellent flexibility, making them ideal for compact, foldable devices. In foldable phones, FPC provides the essential connectivity needed to bridge the phone's display and other components while allowing for continuous motion without wear and tear.

For foldable phones, the primary characteristics of an ideal FPC include:

· High Flexibility: To withstand continuous folding motions.

· Durability: Ensuring longevity, as these circuits must support at least 80,000 to 100,000 folding cycles.

· Lightweight Construction: Necessary to maintain the sleek design of foldable phones.

Why FPC is Essential for Foldable Phones

Foldable phones rely heavily on Flexible Printed Circuits for a smooth user experience. As foldable technology advances, the demands on FPC have increased significantly. The main reason FPC is crucial in foldable phones is that it provides uninterrupted electrical connectivity in areas that require frequent movement, such as the hinge.

The success of a foldable phone depends on the FPC's ability to handle constant folding and unfolding without breaking or degrading. Moreover, the FPC's flexibility is also essential for the phone’s overall durability, especially in the hinge area, where most of the folding action occurs.

A well-designed FPC for foldable phones ensures:

· Reliability: Prevents loss of signal or power, even after thousands of folds.

· Compactness: The flexible nature of FPC allows designers to create slimmer, more compact devices.

· Efficiency: FPC’s capability to integrate multiple layers ensures efficient use of space without sacrificing performance.

Design Considerations for FPC in Foldable Devices

Designing an FPC for foldable phones is a delicate process that requires careful attention to material selection and layout. To meet the unique needs of foldable devices, designers must ensure that FPCs have the right combination of flexibility, durability, and electrical performance.

Here are key considerations:

· Material Selection: Using rolled annealed (RA) copper ensures that the FPC can endure repeated bending without cracking. Thin substrates like 0.5 mil with a cover layer of similar thickness allow for better flexibility.

· Layering and Trace Design: The number of layers and trace width are critical for ensuring electrical performance without compromising flexibility. A two-layer design is typically ideal for foldable phones with a 40-pin connector, using 3-mil traces to handle sufficient current without overloading the circuit.

· Bending Area Optimization: FPC must be designed without vias in the bending area to avoid stress points. Copper traces added to the outer edges provide additional protection and ensure durability in high-stress regions.

The Growing Demand for FPC in the Western Market

The Western market for foldable phones has experienced rapid growth in recent years, with manufacturers like Samsung, Google, and Huawei leading the way. As more consumers in North America and Europe demand innovative mobile technology, the role of FPC in enabling the foldable phone revolution becomes more evident.

In the competitive landscape, Flexible Printed Circuits have become a key differentiator for brands looking to stand out. In the Western foldable phone market, FPCs offer immense value due to their ability to enhance device durability while maintaining sleekness and performance.

Moreover, FPC technology is evolving to meet the ever-increasing demands for higher flexibility, more compact designs, and better power management. As a result, many Western manufacturers are turning to experienced FPC providers, like Gekun, who have a deep understanding of the market and its technical requirements.

Conclusion: Gekun – Your Trusted FPC Manufacturer

In conclusion, Flexible Printed Circuits are indispensable for foldable phones, providing the essential flexibility, durability, and performance needed to support the innovative designs of modern devices. With the foldable phone market expanding rapidly, especially in North America and Europe, having a trusted FPC manufacturer is crucial to success.

Gekun has over 10 years of experience in FPC manufacturing and design, offering top-tier solutions for the electronics industry. Our strong R&D team and advanced technology ensure that we deliver high-quality, reliable FPC solutions for foldable phones and beyond. For more information on how Gekun can support your next project, visit our website. https://gekunflex.com