Imagine a vast network of pipelines carrying water, gas, oil, and other crucial materials across continents. These pipelines rely on silent partners to ensure their integrity and prevent leaks – pipe flanges. The pipe flanges market provides these essential components, and it's poised for steady growth driven by infrastructure development and the ever-present need for safe and reliable pipelines.

Current Landscape: Bolting Down Stability

While the exact market size for pipe flanges might be challenging to isolate due to their inclusion within the broader flange market, their significance is undeniable. Here's a breakdown of the current landscape:

- Types of Flanges: Pipe flanges come in various configurations based on pressure rating, material composition, and connection style. Common types include threaded flanges, welded flanges, and slip-on flanges, each suited for specific pipe applications and pressure requirements.

- Material Diversity: The choice of material for pipe flanges depends on factors like the fluid being transported, pressure rating, and operating temperature. Common materials include steel (carbon steel and stainless steel), but other options like plastic and exotic alloys exist for specialized applications.

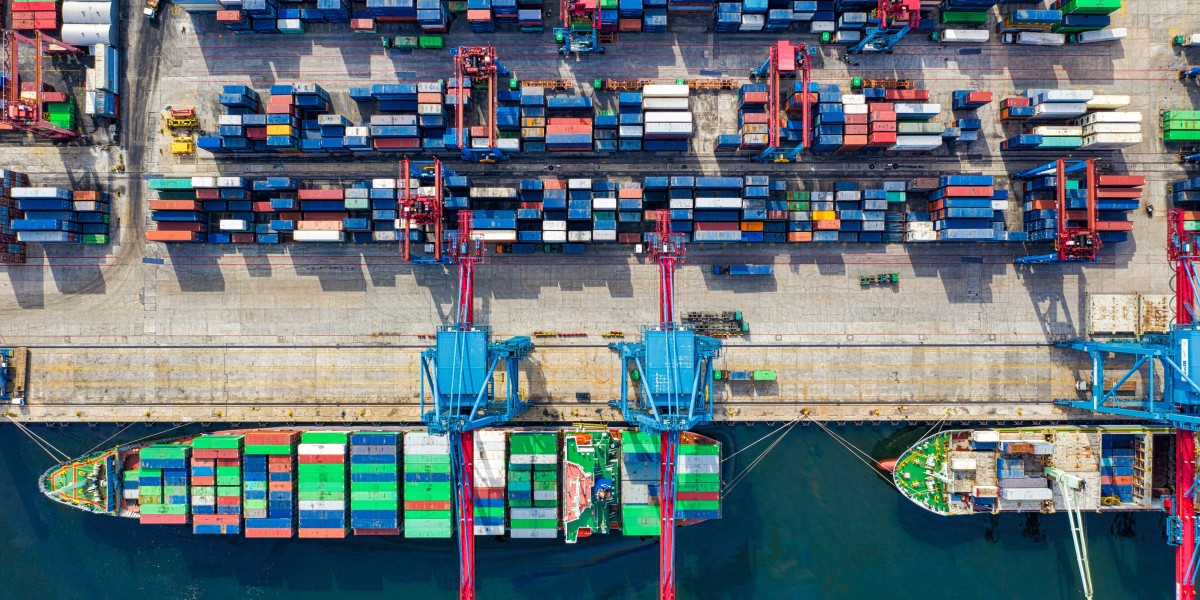

- Industry Applications: Pipe flanges are critical components across various industries that rely on pipelines. These include oil and gas, chemical processing, water and wastewater treatment, power generation, and even marine applications.

Get Exclusive Sample Copy of the Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-17600

Market Drivers: Fueling the Flow of Opportunity

Several key factors are propelling the pipe flanges market forward:

- Growing Demand for Energy: The increasing global demand for energy necessitates the expansion of oil and gas pipelines, which in turn drives the demand for pipe flanges.

- Rising Infrastructure Investment: Investments in infrastructure development, including water supply networks, sewage systems, and power grids, all require robust pipelines secured with reliable pipe flanges.

- Focus on Safety and Regulations: Stringent regulations regarding pipeline safety emphasize the use of high-quality, properly rated pipe flanges to minimize leakage risks.

- Expansion of Chemical Processing Industry: The growth of the chemical processing industry, with its reliance on pipelines for transporting various chemicals, creates a demand for specialized pipe flanges with corrosion resistance.

Market Trends: A Look Ahead

The pipe flanges market is constantly evolving, with several trends shaping the future:

- Focus on Advanced Materials: Developments in material science might lead to the use of stronger, lighter, and more corrosion-resistant materials for pipe flanges, catering to high-pressure and extreme temperature applications.

- Emphasis on Automation and Standardization: The growing adoption of automation in pipeline construction could lead to a demand for standardized pipe flanges that facilitate faster and more efficient installation.

- Focus on Leak Detection Technologies: Advancements in leak detection technologies might influence the design of pipe flanges to incorporate features that enable easier leak identification and quicker maintenance response.

- Sustainability Considerations: The growing focus on sustainability could lead to the development of pipe flanges with improved recyclability or the use of recycled materials in their production.

Opportunities for Manufacturers: Securing their Place in the Pipeline

Manufacturers in the pipe flanges market can capitalize on these trends by focusing on several key strategies:

- Product Innovation: Developing next-generation pipe flanges with improved material properties, innovative designs for easier installation, and potential leak detection functionalities can give manufacturers a competitive edge.

- Focus on Quality and Certifications: Maintaining high-quality standards and adhering to relevant industry certifications for pipe flanges is crucial for building trust and brand reputation.

- Global Market Expansion: Exploring opportunities in developing regions with growing infrastructure projects allows manufacturers to tap into new markets.

- Emphasis on After-Sales Support: Providing readily available spare parts, efficient technical support, and training programs for installers strengthens customer relationships and brand loyalty.

Read more info: https://www.futuremarketinsights.com/reports/pipe-flange-market