Welcome to our detailed analysis of the Production Cost of Aniline, a fundamental chemical compound with wide-ranging industrial applications. In this article, we'll delve into the intricacies of Aniline production, examining key factors that influence costs, raw materials, manufacturing processes, and market dynamics.

Definition:

Aniline, also known as aminobenzene or phenylamine, is an organic compound with the chemical formula C6H5NH2. It is a colorless to pale yellow liquid with a characteristic odor, and it is primarily used as a precursor in the production of various chemicals, including dyes, pharmaceuticals, rubber processing chemicals, and agricultural chemicals.

Request For Free Sample: https://www.procurementresource.com/production-cost-report-store/aniline/request-sample

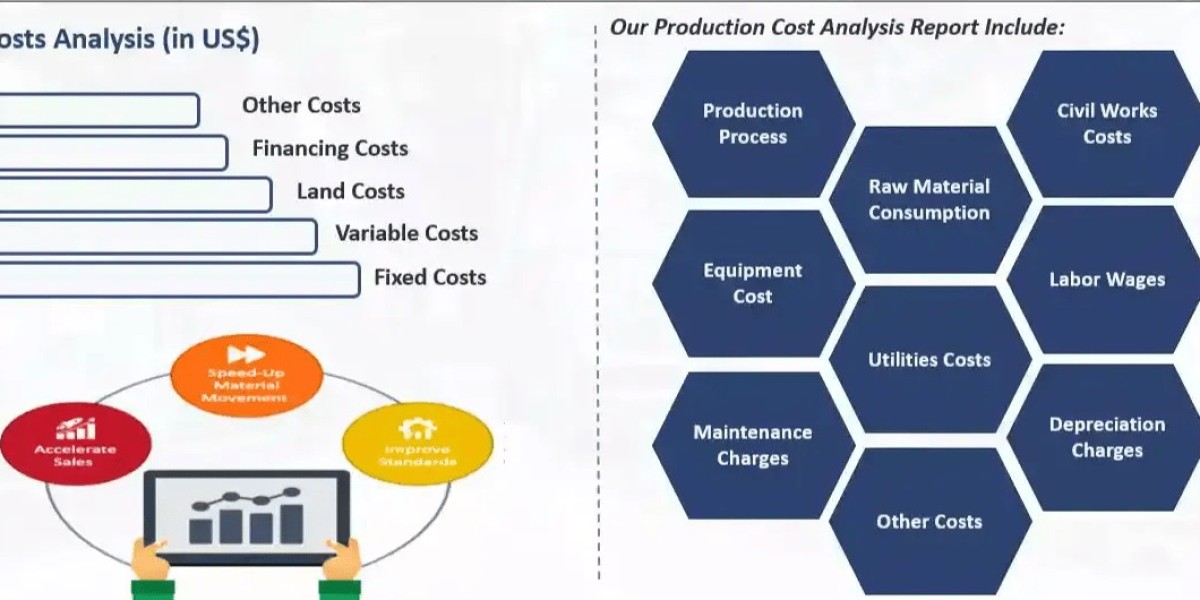

Key Details About Aniline Production Cost:

Raw Materials: The primary raw material for Aniline production is benzene, which is derived from petroleum refining or coal tar distillation. Benzene undergoes a catalytic hydrogenation process to produce cyclohexane, which is then oxidized using a metal catalyst to form nitrobenzene. Nitrobenzene is subsequently reduced to Aniline through a catalytic hydrogenation process.

Manufacturing Process: The production of Aniline involves several steps, including:

- Hydrogenation of benzene to cyclohexane

- Oxidation of cyclohexane to nitrobenzene

- Reduction of nitrobenzene to Aniline Each step requires specific catalysts, solvents, and process conditions to achieve high conversion rates and product yields.

Energy Consumption: Aniline production is energy-intensive, requiring significant amounts of heat and electricity for various unit operations, including heating, mixing, and distillation. Energy costs constitute a significant portion of the overall production cost and are influenced by factors such as energy efficiency, fuel prices, and process optimization.

Labor and Overhead Expenses: Labor costs associated with operating and maintaining production facilities, as well as overhead expenses such as administrative costs, utilities, and maintenance, contribute to the overall production cost of Aniline. Labor requirements may vary depending on the scale of production and level of automation.

Industrial Uses Impacting Aniline Production Cost:

The demand for Aniline is driven by its versatile applications across several industries, including:

- Dye Manufacturing: Aniline is a crucial raw material in the production of various dyes and pigments used in textiles, printing inks, and coatings.

- Pharmaceuticals: Aniline derivatives are used in the synthesis of pharmaceuticals, including analgesics, antibiotics, and anti-inflammatory drugs.

- Rubber Processing: Aniline-based chemicals are utilized as accelerators and antioxidants in the vulcanization of rubber.

- Agricultural Chemicals: Aniline derivatives are employed as intermediates in the production of herbicides, fungicides, and insecticides.

Key Players:

Several major chemical companies are involved in the production of Aniline, including:

- BASF SE

- Dow Chemical Company

- Covestro AG

- Huntsman Corporation

- Sumitomo Chemical Company Limited

These companies operate large-scale manufacturing facilities and leverage advanced technologies to produce Aniline efficiently and cost-effectively.

Conclusion:

In conclusion, the production cost of Aniline is influenced by various factors, including raw material prices, energy costs, market demand, and regulatory compliance. Understanding these factors is essential for producers and stakeholders in the chemical industry to optimize production processes, manage costs, and remain competitive in the market. As Aniline continues to be a vital component in the production of dyes, pharmaceuticals, rubber processing chemicals, and agricultural chemicals, insights into its production cost dynamics play a crucial role in strategic decision-making and business planning within the chemical sector.