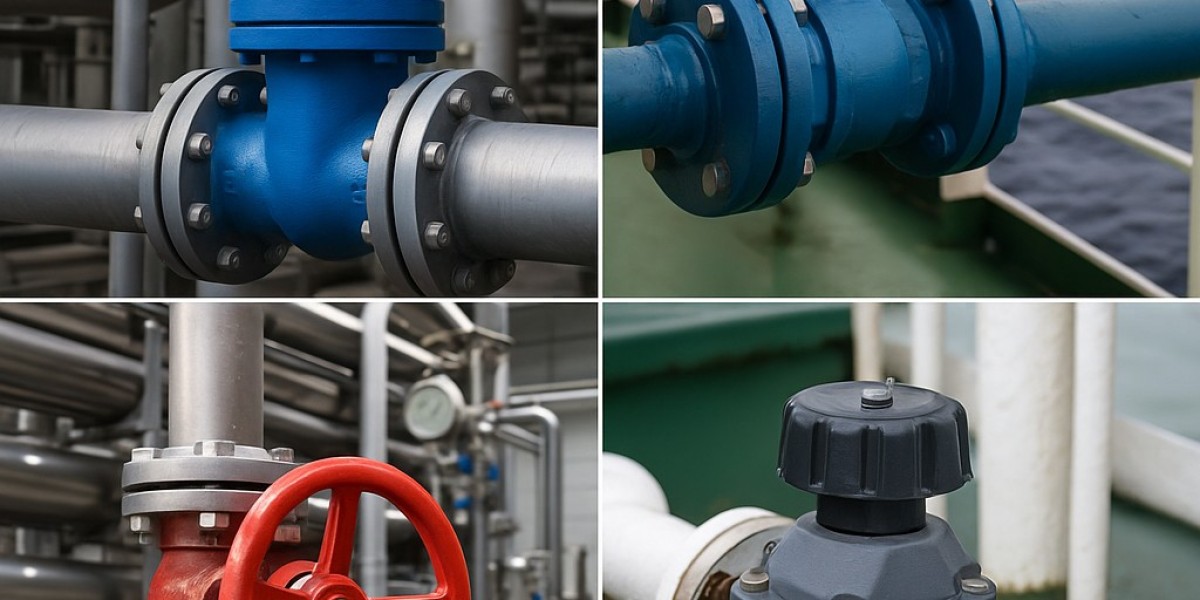

Control valves are essential in marine and industrial environments, where they manage the flow, pressure, and temperature of various fluids to ensure complex systems operate efficiently. As automation becomes increasingly prevalent in these sectors, the demand for precise and reliable control valves has never been greater.

SUN, a leader in automation solutions, provides a wide range of high-performance control valves designed for challenging marine and industrial conditions. This guide explores how control valves work, their types, and specific applications, helping professionals make informed decisions.

What Are Control Valves?

Control valves are devices that regulate the flow of fluids by varying the size of flow passages. They also control system pressure, fluid levels, and temperatures. Operated by actuators, these valves respond to signals from control systems, ensuring accuracy and reliability—especially critical in marine operations and industrial processes.

Types of Control Valves and Their Functions

1. Globe Valves

- Function: Ideal for throttling and flow regulation, globe valves provide precise control due to their internal design.

- Applications: Widely used in systems requiring accuracy, such as marine fuel oil circuits, steam lines, and industrial cooling systems.

2. No

- It was: Known for durability and tight sealing, ball valves excel in on/off control rather than modulation.

- Applications: With

3. Butterfly Valves

- It was: Cost-effective and compact, butterfly valves offer quick shutoff and are suited for space-limited areas.

- Applications: Used in ballast and cargo systems on ships, as well as in industrial HVAC and water treatment systems.

4. Diaphragm Valves

- Functionality: Their contamination-free operation makes them suitable for corrosive fluids and sensitive applications.

- Applications: Frequently found on ships for water treatment and in chemical industries handling aggressive substances.

5. Needle Valves

- Functionality: Designed for fine-tuned flow control, needle valves are ideal for low-flow applications.

- Applications: Used in marine fuel systems and industrial instruments requiring calibration and precision.

Key Application Areas

Marine Applications

- Fuel But: Ensures efficient combustion in engines and boilers by precisely controlling fuel flow.

- Wall: Manages the intake and discharge of ballast water to maintain vessel stability and buoyancy.

- Cooli: None

Industry

- Process Control: Used in sectors like chemical manufacturing to manage the flow of materials, ensuring accurate chemical reactions and consistent product quality.

- Water Treatment: Controls flow rates for chemical dosing and filtration processes, maintaining system performance and water quality.

Benefits of High-Quality Control Valves

- Increased Efficiency: Accurate flow regulation improves system performance and reduces energy consumption.

- Enhanced Safety: Reliable valves prevent overpressure, leaks, and equipment failure, minimizing operational hazards.

- Long-Term Durability: Investing in robust control valves reduces maintenance frequency and enhances system uptime.

Why choose RAM Automations for Control Valves?

At RAM Automations, we offer a comprehensive selection of control valves from trusted brands such as Siemens, ABB, and Bosch.

Conclusion

Control valves are vital for efficient and safe operations in both marine and industrial sectors. Understanding the various valve types and their respective applications allows businesses to enhance system performance and reliability.

RAM Automations is committed to providing top-tier control valves and expert guidance, ensuring that your systems run smoothly and meet the demands of today's evolving technologies.