Industrial facilities, research laboratories, and even educational institutions frequently deal with waste that contains acidic components. Whether these acids come from chemical processes, laboratory experiments, or manufacturing byproducts, one fact remains clear: they cannot be discharged directly into municipal sewer systems without proper treatment.

Municipalities across North America, particularly in Canada and the United States, enforce strict regulations on wastewater discharge to protect public health, infrastructure, and the environment. The penalties for non-compliance can be severe—ranging from costly fines to mandatory shutdowns.

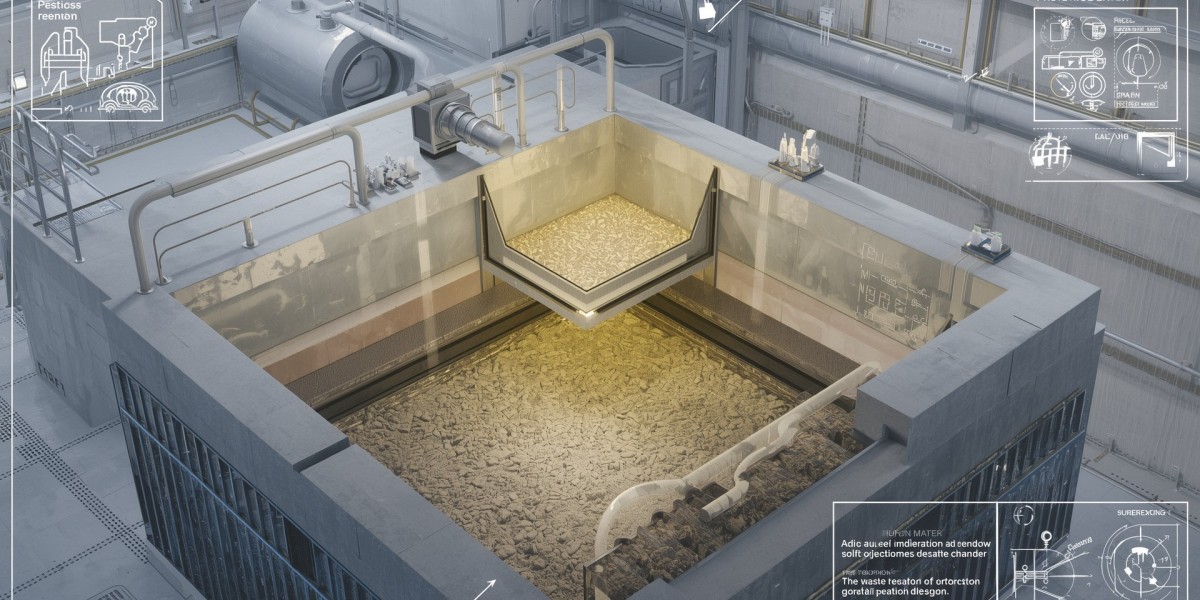

This is where neutralization pit design comes into play. By implementing a properly engineered acid neutralization system, facilities can ensure that waste is treated to acceptable pH levels before it enters the municipal network. Not only does this safeguard the environment, but it also prevents costly damage to pipes, drains, and other wastewater infrastructure.

The Role of Neutralization Pit Design in Wastewater Management

At its core, neutralization pit design is about creating a system that provides the right environment for acidic wastewater to react with alkaline agents (most often limestone) until it reaches a safe pH level. The design process involves several crucial considerations:

Gallons per Hour of Waste Flow

Accurately estimating the flow rate is essential for sizing the system. A typical recommendation is to assume one gallon per hour per fixture unit if exact numbers aren’t available.pH Levels of Incoming Waste

Stronger acids require longer contact times with the neutralizing agent. This is why understanding the waste’s initial pH is vital.Retention Time

A minimum of one hour of contact time is recommended, though some guidelines, like those from ASPE (American Society of Plumbing Engineers), suggest dwell times of 2½ to 3 hours for optimal results.

Tank Sizing

The capacity of the tank must be matched to the facility’s waste volume and operational needs. Undersized tanks risk allowing untreated waste to pass through; oversized tanks provide future expansion capacity.