Are you looking for an efficient way to manufacture high-quality products at scale? Whether you're a small startup or a well-established company, injection molding services could be the game-changer you need. Think of it as baking a cake: you pour the batter into a mold, let it set, and out comes the perfect shape every time. The same principle applies here but with materials like plastic, rubber, or metal—and on a much grander scale.

1. What is Injection Molding?

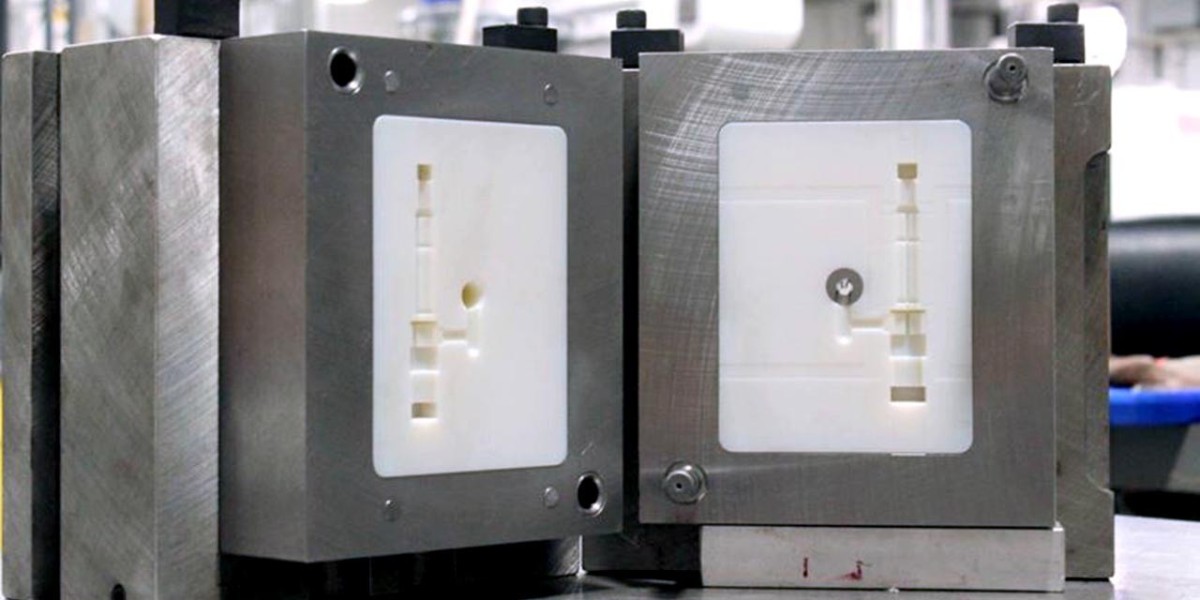

Injection molding is a manufacturing process used to produce parts in large quantities. It involves injecting molten material into a mold, which shapes the material as it cools. This method is widely used to create everything from small plastic parts to complex components in industries like automotive and healthcare.

2. How Does Injection Molding Work?

The process of injection molding is simple yet efficient. Here’s how it works:

Material Preparation: Raw materials like plastic pellets are melted into a liquid state.

Injection: The molten material is injected into a pre-designed mold at high pressure.

Cooling: The material cools and solidifies inside the mold.

Ejection: The finished product is ejected from the mold, ready for use or additional finishing.

3. Advantages of Injection Molding Services

Injection molding offers numerous benefits, making it a go-to solution for businesses looking to scale production efficiently. Let’s explore the key advantages.

4. Cost-Effectiveness of Injection Molding

Are you worried about manufacturing costs? Injection molding helps reduce expenses by minimizing material waste and optimizing production times. Once the mold is created, the cost per unit drops significantly, especially for high-volume production.

5. Precision and Consistency

One of the standout benefits of injection molding is its ability to produce parts with incredible accuracy. Whether it’s a tiny gear or a large housing, you can expect consistent results every time, ensuring product quality.

6. Fast Production with High Scalability

Need thousands of parts in a short time? Injection molding delivers. The process is designed for speed, making it ideal for businesses that need to scale production without compromising quality.

7. Versatility in Material Choices

Injection molding works with a wide range of materials, including plastics, metals, and elastomers. This versatility allows businesses to create products tailored to specific needs, whether it’s durability, flexibility, or aesthetics.

8. Environmental Benefits of Injection Molding

Contrary to popular belief, injection molding can be eco-friendly. Many manufacturers use recyclable materials, and the process itself generates minimal waste. Additionally, advancements in technology have made it more energy-efficient.

9. Applications of Injection Molding in Different Industries

Injection molding is used across various industries. Here are some examples:

Automotive: Dashboard components, engine parts

Medical: Syringes, surgical tools

Consumer Goods: Bottle caps, toys

Electronics: Housings for gadgets

10. Why Choose MechPower for Injection Molding Services?

At MechPower, we pride ourselves on delivering top-notch injection molding services. With state-of-the-art equipment and a team of experienced professionals, we ensure your products meet the highest standards. Plus, our commitment to sustainability sets us apart.

11. Tips for Choosing the Right Injection Molding Partner

Finding the right partner is crucial. Here are some tips:

Check their experience and expertise.

Evaluate their equipment and technology.

Ask for samples and client testimonials.

Ensure they align with your sustainability goals.

12. Common Misconceptions About Injection Molding

Let’s bust some myths:

Myth: It’s only for large companies. Fact: Businesses of all sizes can benefit from injection molding.

Myth: It’s expensive. Fact: While the initial investment might be high, the long-term cost savings are substantial.

13. FAQs

1. What materials can be used in injection molding?

Injection molding works with various materials, including plastics, metals, and elastomers. The choice depends on the product’s requirements.

2. Is injection molding suitable for small businesses?

Absolutely! Small businesses can use injection molding for small-batch production or prototype development.

3. How long does it take to create a mold?

The mold-making process can take anywhere from a few weeks to a couple of months, depending on complexity.

4. Can injection molding handle complex designs?

Yes, modern injection molding technology can produce intricate and detailed parts with high precision.

5. What are the environmental benefits of injection molding?

Injection molding generates minimal waste, uses recyclable materials, and has become more energy-efficient over the years.

Conclusion

Injection molding services offer businesses a reliable and cost-effective way to produce high-quality products at scale. From precision to versatility, the benefits are undeniable. If you’re ready to take your manufacturing to the next level, consider partnering with MechPower for all your injection molding needs. It’s time to mold your ideas into reality!