Introduction:

As leading Fly Ash Bricks Making Machine Manufacturers in Madhya pradesh, we are excited to share the transformative potential of these bricks in modern construction. This article explores the incredible advantages of using fly ash bricks and why they represent the future of construction.

What Are Fly Ash Bricks?

Fly ash bricks are an innovative building material made from the byproduct of coal combustion in thermal power plants. These bricks comprise fly ash, cement, sand, and water, mixed and molded into sturdy, uniform bricks. Unlike traditional clay bricks, fly ash bricks do not require kiln firing, making them an environmentally friendly alternative.

The Incredible Advantages of Fly Ash Bricks

Eco-Friendly Marvels

Fly ash bricks are a green building marvel. By utilizing fly ash, which is a waste product, these bricks significantly reduce environmental pollution. Their production process emits far less carbon dioxide compared to traditional clay brick manufacturing, contributing to a cleaner, greener planet.

Cost-Effective Construction

The production of fly ash bricks is highly economical as it utilizes industrial waste products. This cost-efficiency extends to construction, where the use of these bricks can significantly lower overall building costs due to their durability and minimal maintenance requirements.

Unmatched Strength and Durability

Fly ash bricks are celebrated for their high compressive strength and durability. They offer superior load-bearing capacity compared to traditional clay bricks, making them ideal for constructing high-rise buildings. As Fly Ash Bricks Making Machine Manufacturers in Ranchi, we are proud of the exceptional quality and longevity of our fly ash bricks.

Superior Thermal Insulation

Fly ash bricks provide excellent thermal insulation, enhancing energy efficiency in buildings. Structures built with these bricks maintain a cooler interior in summer and a warmer environment in winter, reducing the need for artificial heating and cooling.

Fly Ash Bricks vs. Traditional Clay Bricks

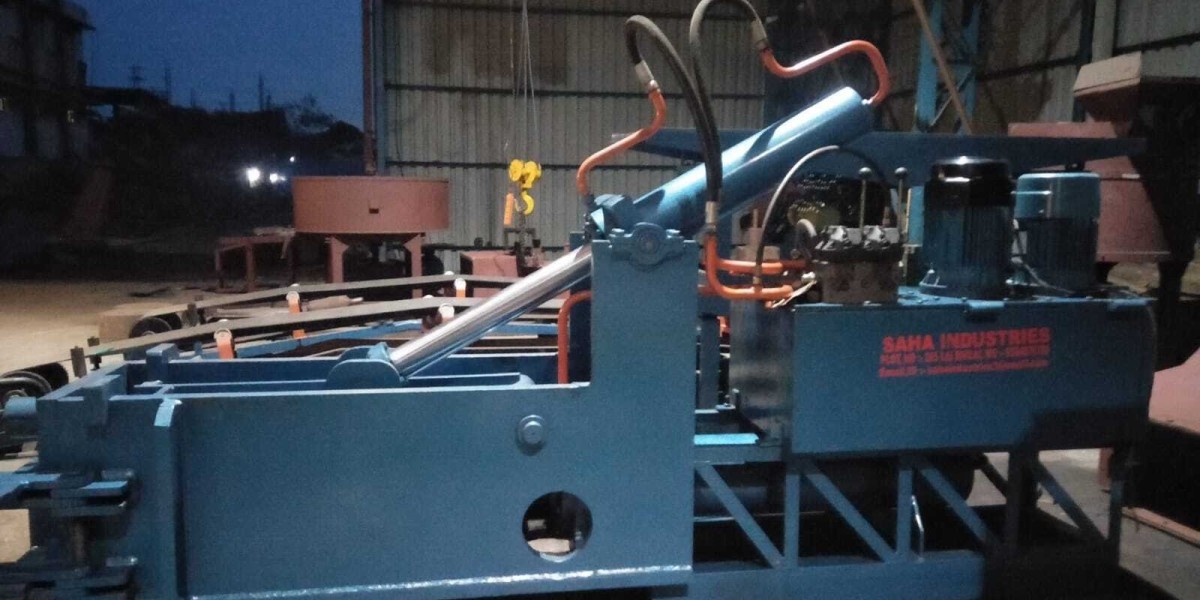

Advanced Manufacturing Process

The production of fly ash bricks involves advanced automatic machines that ensure uniformity and precision. This modern approach contrasts with the labor-intensive and energy-consuming process of traditional clay brick manufacturing.

Sustainability at Its Best

Fly ash bricks are a sustainable alternative as they recycle industrial waste and reduce the need for clay, thereby conserving topsoil. Traditional clay brick production depletes fertile soil and emits higher levels of greenhouse gases.

Efficiency in Construction

Thanks to their uniform shape and size, fly ash bricks require less mortar during construction, resulting in faster and more efficient building processes. Their lightweight nature also reduces the dead load on structures, enhancing seismic performance.

Versatile Applications of Fly Ash Bricks

Fly ash bricks are incredibly versatile and can be used in a variety of construction projects, including residential buildings, commercial complexes, and infrastructure developments. Their exceptional properties make them suitable for load-bearing and non-load-bearing walls, foundations, and other structural elements.

Conclusion

The future of construction is bright with the advent of sustainable and efficient materials like fly ash bricks. With their myriad benefits, including environmental friendliness, cost-effectiveness, and superior performance, fly ash bricks are set to become the cornerstone of tomorrow's buildings. As pioneers in the manufacturing of fly ash bricks and related machinery, we are thrilled to promote the adoption of these innovative materials in the construction industry.

By choosing fly ash bricks, builders and developers can contribute to a greener planet while ensuring the durability and efficiency of their projects. Embrace the future of construction with fly ash bricks and experience the incredible transformation they bring to the building landscape.