In modern web handling systems, equipment like Banana Rollers plays a crucial role in maintaining optimal material alignment and web tension. These specially curved rollers are vital in industries that process paper, plastic film, textiles, and nonwovens—especially where wrinkling or overlapping of material can disrupt production. With growing demands for efficiency and accuracy, manufacturers must incorporate technology that not only improves output but also minimizes waste and downtime.

One of the primary purposes of these curved rollers is to eliminate wrinkles and maintain proper tension across the entire web. Their unique bowed shape redistributes tension and stretches the web laterally, correcting uneven movements that typically occur during high-speed operations. Unlike flat rollers, which might allow web materials to gather or wrinkle, the arched design ensures even tension from edge to edge, providing a consistent and smooth path for the material.

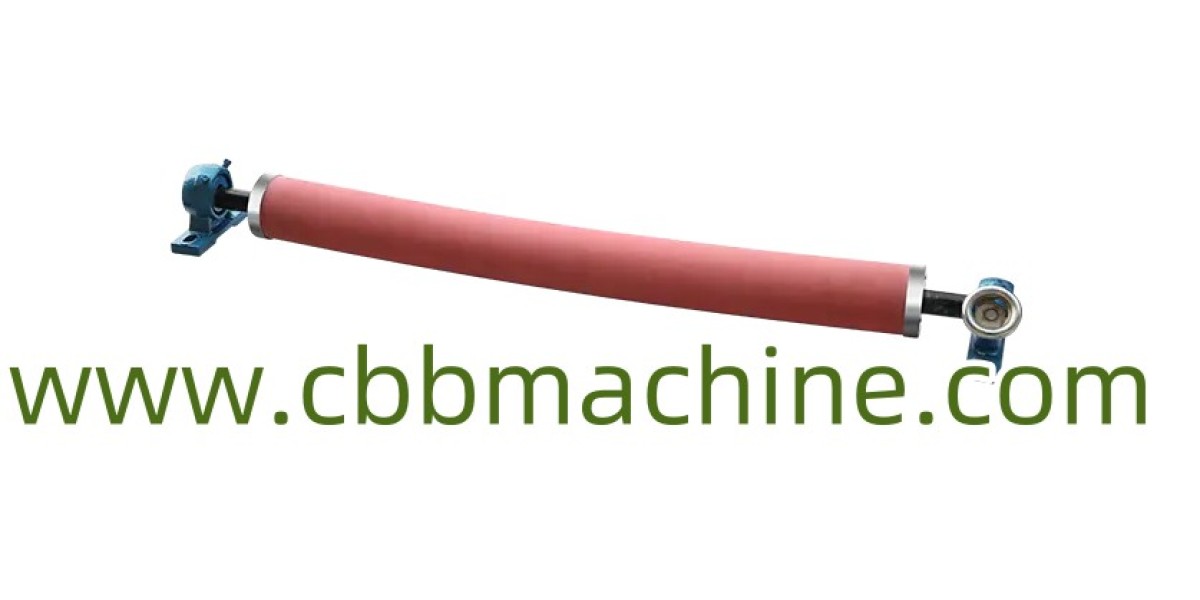

The structural design and materials used in these rollers are just as important as their function. Typically made from lightweight aluminum or stainless steel, these rollers are engineered for both durability and smooth rotation. The surface is often coated or anodized to prevent material sticking and wear over time. Some models include bearings or shafts designed for high-speed rotation, reducing vibration and noise while improving stability. In advanced production settings, they may also be integrated with sensors or tracking systems for more precise control.

Customization is a key benefit when sourcing these rollers from reputable manufacturers. The arc length, diameter, coating material, and installation method can all be tailored to suit different machine setups and application needs. For instance, printing lines might require smaller diameters for compact spaces, while film extrusion operations could need extended arc lengths to handle wider webs. Manufacturers like cbbmachine offer tailored roller solutions to ensure seamless integration with your existing systems.

Proper installation and maintenance are essential for maximizing the lifespan of these rollers. Incorrect setup can result in uneven spreading or even cause damage to the material. Technicians should carefully align the roller according to web direction and ensure it rotates freely without resistance. Periodic cleaning and inspection help prevent buildup that could alter the roller's performance. With correct usage, these rollers can last many years and provide consistent results throughout their service life.

What distinguishes modern rollers from earlier designs is the engineering precision behind their curvature. Advanced manufacturing techniques allow for exact bending of the core shaft, creating uniform tensioning performance throughout the roller's rotation. This reduces strain on the material, especially for sensitive or delicate substrates like ultra-thin plastic films, coated papers, or composite textiles. As a result, these rollers are not just accessories—they are vital components in maintaining quality control and increasing line productivity.

As industrial processes continue to evolve, the need for reliable, adaptable, and performance-driven components will only increase. Choosing the right tension control devices can drastically improve product quality and machine efficiency. By incorporating precision-engineered solutions such as these, manufacturers can reduce waste, optimize line speeds, and ensure high-quality output across every batch.

To explore customizable options and learn how these rollers can improve your operations, visit https://www.cbbmachine.com/product/banana-roller/customizable-banana-roller.html