The growth of electronics has led to the massive progress of telecom infrastructure. Manufacturers are using various types of electronic components to start a new generation of gadgets and devices. Among the millions of small, nano components used on these circuit boards are LEDs. Here we trace the evolution of Surface Mount LEDs and the use of LED panels in industries.

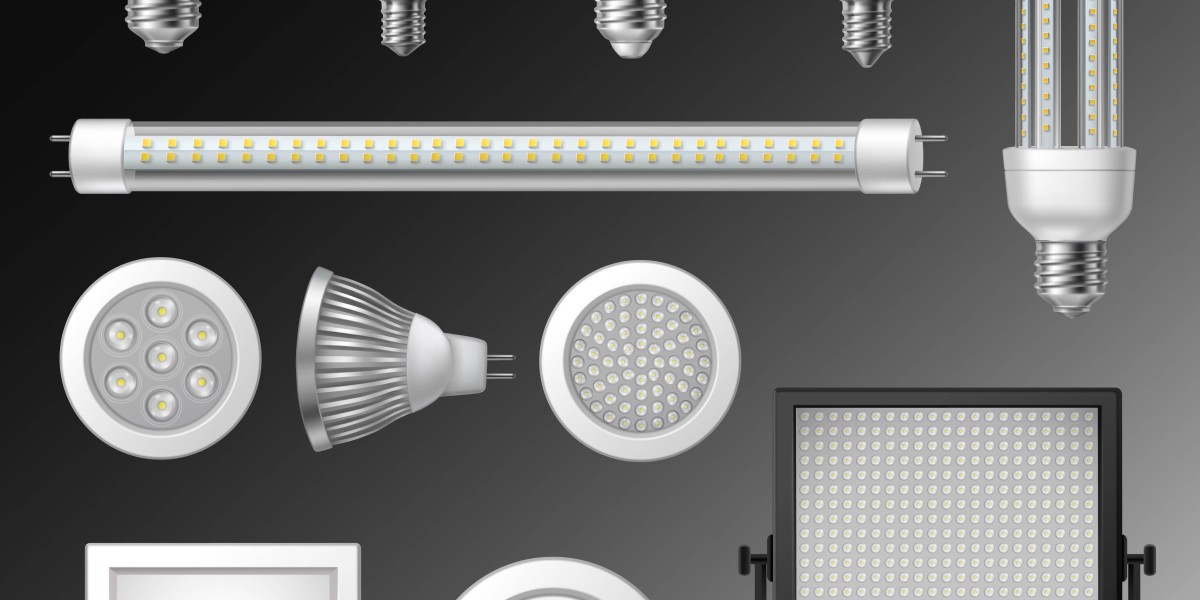

What are Surface Mount LEDs?

Surface Mount LEDs also called SMT LEDs are used extensively in many devices. Surface Mount is a process that places components onto the surface of a printed circuit board. The components are not hardwired but designed for mounting onto the circuit board. The SMT LEDs are smaller in size and have a longer life span.

Some of the most common advantages of surface mount LEDs are their low-cost and brightness.

But, what are LEDs? Light-Emitting diodes are solid-state devices that transform electric energy into light. They differ from electric bulbs by passing an electric current through a semiconducting material. Like a filament that glows when electricity is passed through regular bulbs, these LED bulbs emit photons. Electroluminescence occurs, and we see that as LED light.

LEDs are different from incandescent and CFL bulbs as well. These types of bulbs emit light from a vacuum or gas unlike LEDs that emit light from solid matter by using a semiconductor. The most commonly used material in LEDs is gallium arsenide.

What is an LED Panel?

An LED panel display consists of an array of LEDs as the light source. Hence, these components are used extensively in a range of electronic devices. The most common consumer electronics goods that use LED panels are televisions, monitors, and indoor/outdoor digital signage.

LED panels are sometimes called LED troffers as well. One of the primary reasons for LED panels being used extensively is because they are low-cost, sustainable alternatives. Lately, they are replacing more expensive fluorescent lighting to achieve higher energy-efficiency.

The advantage of using LEDs is their flexible designs. They can be rectangular, curved, or flat and placed on the wall, ceiling, or door or recessed, surface mounted.

LED panels are typically aluminum frames with a high-end indoor lighting fixture. The light passes through the light guide plate with high transmittance to form a uniform plane luminous effect. For indoor lighting, they are used extensively in enclosure lights and cabinets.

LED panels offer energy efficiency, longer lifespan and high-quality output. They are durable and have very low UV emissions. Their eco-friendliness too have made them industry favorites. Besides, they ensure instant lighting and are unlikely to suffer from technical glitches or be impacted by bugs and moths. Thus, LED panels are very effective for large spaces: LED panels can deliver higher output with less energy consumption, which is especially effective for large spaces.

How did Surface Mount LEDs come to be used?

The evolution of surface mount technology from through-hole technology has been gradual. In its original avatar, called "planar mounting" was begun byIBM in 1960. By the mid-1980s, almost every manufacturer was using SMT, and by the late 1990s, it dominated high-tech electronic printed circuit assemblies. Thus SMT LEDs are used extensively as lighting alternatives to replace expensive lighting. It ensures long term lighting solutions that are sustainable for industries that consume expensive electricity. At the same time,

LED panels are used in many types of consumer electronics for brighter displays. In industries, LED panels are used to illuminate passages and productivity spaces. These are ideal as lighting panels for controlling electric lighting systems and contain controls, switches Their durability and low UV emissions have made them the most ecologically friendly. Instant lighting is another big advantage.