In today’s fast-paced industrial world, the demand for cleaner, more efficient, and sustainable methods of metal surface cleaning is higher than ever. Enter the laser metal cleaner – a cutting-edge technology that promises to revolutionize metal cleaning with unparalleled precision and effectiveness. This innovative solution is a game-changer for industries seeking an eco-friendly, time-saving alternative to traditional cleaning methods.

What is a Laser Metal Cleaner?

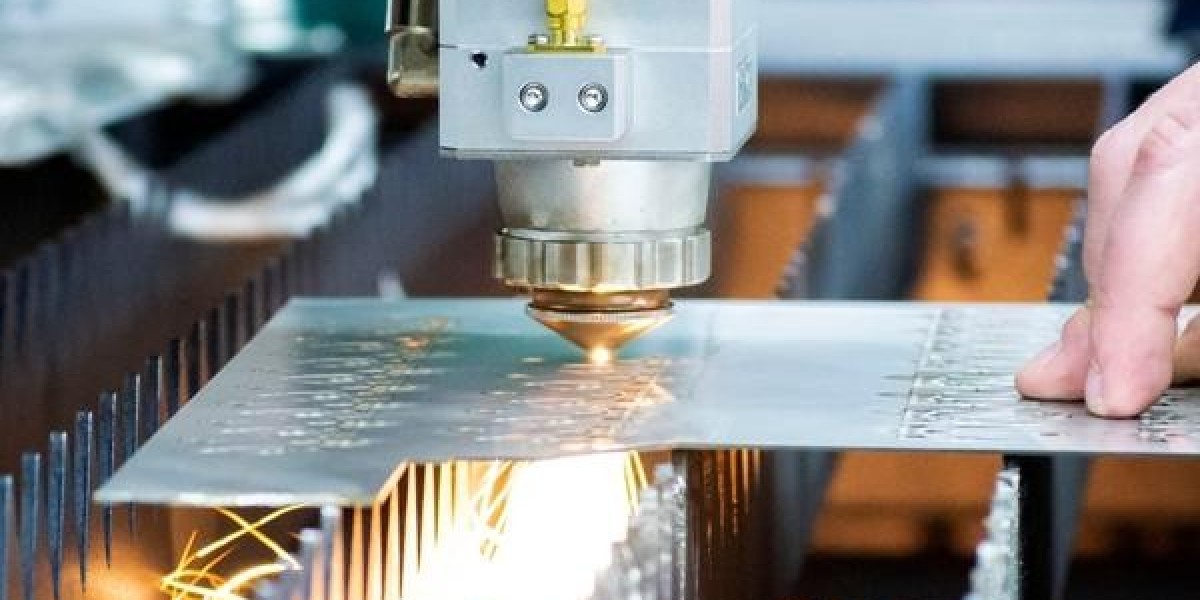

A Laser Metal Cleaner uses high-powered lasers to remove contaminants such as rust, dirt, oil, and paint from metal surfaces. Unlike traditional cleaning methods that involve harsh chemicals, abrasives, or water-based systems, laser cleaning is non-contact, environmentally friendly, and highly effective in achieving superior results. The laser beam, directed at the metal surface, creates high-intensity heat that vaporizes and removes unwanted material without damaging the base metal itself.

Why Choose Laser Metal Cleaning?

Eco-Friendly & Sustainable: Laser cleaning eliminates the need for harsh chemicals or abrasive materials, making it an environmentally safe alternative to traditional cleaning methods. No harmful waste or pollutants are produced, reducing your company’s carbon footprint.

Precision & Efficiency: Laser technology offers an unprecedented level of precision, allowing for meticulous removal of contaminants down to microscopic levels. Whether you're cleaning large machinery or intricate parts, laser cleaning guarantees excellent results with minimal effort.

Cost-Effective: While the initial investment in a laser metal cleaner may be higher compared to traditional methods, the long-term savings are substantial. With reduced maintenance costs, minimal waste production, and faster processing times, companies can recover their investment quickly.

No Need for Consumables: Traditional cleaning methods require regular purchase of consumables like chemicals, brushes, and abrasives. With laser cleaning, no consumables are needed, as the technology works by harnessing the power of light to remove debris. This drastically reduces operational costs and enhances productivity.

Versatility: Laser metal cleaning is highly versatile and can be applied to various materials, including steel, aluminum, copper, and more. Whether you’re cleaning industrial machinery, automotive parts, or delicate components, the laser cleaner adapts to your specific needs.

Applications of Laser Metal Cleaning

Laser metal cleaning technology has a wide range of applications across multiple industries. Some key use cases include:

- Automotive Industry: Removing rust, scale, and paint from components such as engine parts, chassis, and body panels.

- Manufacturing & Production: Cleaning large machinery, tools, and parts without the need for disassembly, reducing downtime.

- Aerospace & Defense: Precision cleaning of critical parts like turbine blades, ensuring optimal performance and safety.

- Art & Heritage Conservation: Gentle removal of corrosion or oxidation from metal artifacts and statues to preserve their original beauty.

How Does Laser Cleaning Work?

Laser metal cleaning works by directing a high-energy laser beam onto the contaminated metal surface. As the laser light strikes the surface, it heats the contaminants to a temperature where they vaporize or are ejected from the surface. The process is non-contact, meaning the laser does not physically touch the surface, reducing the risk of damage. Additionally, the laser can be adjusted to different intensity levels, allowing for tailored cleaning to suit different materials and levels of contamination.

The Future of Metal Cleaning

As industries move toward more sustainable practices and seek ways to improve productivity, the adoption of laser metal cleaner is expected to grow rapidly. This technology is not only an effective solution for cleaning but also offers a glimpse into a future where manufacturing processes are cleaner, faster, and more environmentally friendly.

Conclusion

Laser metal cleaning is transforming the way industries clean their metal surfaces. With its precision, efficiency, eco-friendly nature, and wide array of applications, it is fast becoming the go-to method for modern cleaning needs. Whether you're looking to enhance your company’s operations or take advantage of a cutting-edge technology, the laser metal cleaner offers a smart, sustainable solution for all your metal cleaning requirements.