In the world of modern manufacturing, various materials and processes play a crucial role in creating durable, high-quality, and functional products. Among these, TPU material, PET, CNC machining, plastic rivets, and overmolding are widely used in industries ranging from automotive and electronics to consumer goods and medical devices.

At FirstMold, we specialize in advanced manufacturing solutions, including precision molding and machining, ensuring our clients receive top-quality components tailored to their needs. In this article, we will explore these five important topics to help you understand their applications, benefits, and why they are essential in today's industrial world.

What is TPU Material?

TPU material (Thermoplastic Polyurethane) is a versatile polymer known for its flexibility, durability, and resistance to abrasion, oil, and chemicals. It is widely used in various industries, including footwear, automotive parts, medical devices, and consumer electronics.

Key Properties of TPU Material:

- Flexibility and Elasticity: Unlike rigid plastics, TPU material has excellent elasticity, making it ideal for flexible components such as phone cases, cables, and seals.

- High Impact Resistance: It absorbs shocks and resists tearing, making it perfect for protective covers and industrial applications.

- Chemical and Abrasion Resistance: TPU material withstands exposure to oils, greases, and harsh chemicals, ensuring long-lasting performance.

- Recyclability: It is a thermoplastic, meaning it can be melted and reshaped multiple times, making it an environmentally friendly option.

Applications of TPU Material:

- Footwear: Used in high-performance sports shoes for flexibility and durability.

- Automotive Parts: Common in seals, gaskets, and protective coatings.

- Medical Devices: Used in tubing, catheters, and protective coverings.

- Consumer Electronics: Found in phone cases, smartwatch bands, and flexible cables.

What is PET?

PET (Polyethylene Terephthalate) is a lightweight, strong, and recyclable plastic widely used in packaging, textiles, and manufacturing.

Key Properties of PET:

- High Strength and Durability: PET is resistant to impact and wear, making it a reliable material for various applications.

- Lightweight: It is commonly used in food and beverage packaging due to its lightness.

- Chemical Resistance: PET can withstand exposure to many chemicals, making it suitable for industrial and medical uses.

- Recyclability: One of the most recycled plastics globally, reducing environmental impact.

Applications of PET:

- Packaging: Used for water bottles, food containers, and cosmetic packaging.

- Textiles: Found in polyester fibers for clothing, carpets, and upholstery.

- Engineering Applications: Used in 3D printing and industrial components.

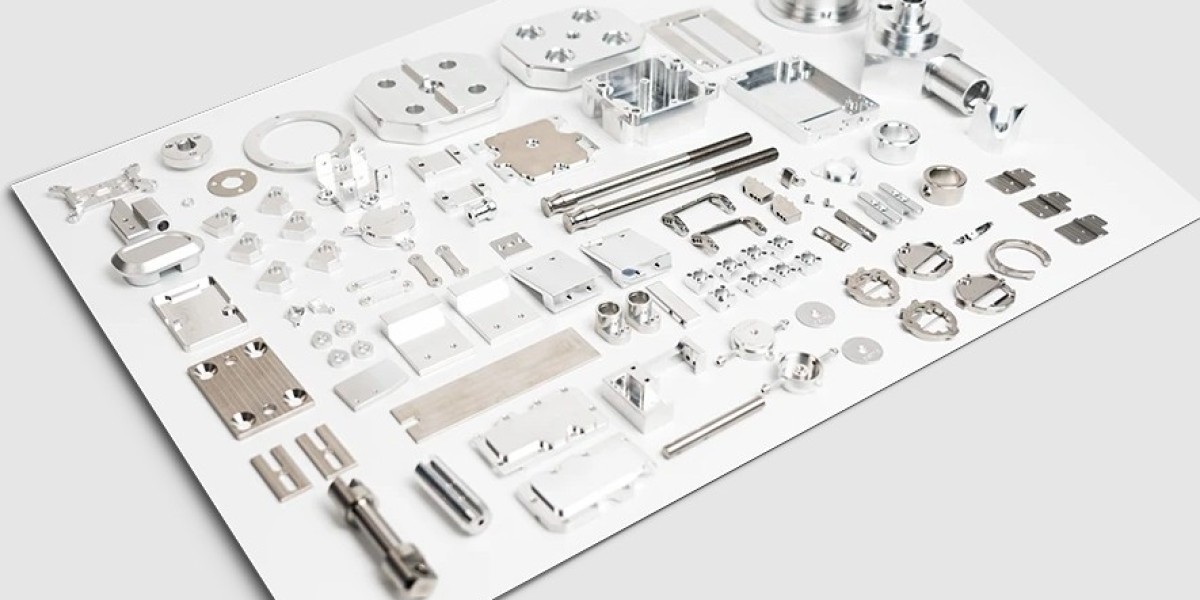

What is CNC Machining?

CNC machining (Computer Numerical Control machining) is a manufacturing process that uses computer-controlled machines to precisely cut, shape, and drill materials. This method is essential for producing high-quality, complex parts with minimal human intervention.

Benefits of CNC Machining:

- Precision and Accuracy: CNC machining ensures high-precision parts with tight tolerances.

- Efficiency and Speed: Automated operations reduce production time and improve efficiency.

- Material Versatility: CNC machining works with metals, plastics, composites, and more.

- Consistency: Produces identical parts with minimal variation, essential for mass production.

Applications of CNC Machining:

- Automotive Industry: Used for engine parts, transmission components, and custom prototypes.

- Aerospace Industry: Produces lightweight, high-strength components for aircraft.

- Medical Industry: Manufactures surgical instruments and implants with extreme precision.

- Electronics Industry: Creates circuit boards, connectors, and specialized casings.

At FirstMold, we specialize in CNC machining, offering high-quality, precision-machined parts tailored to our clients’ needs.

Plastic Rivets: A Secure and Versatile Fastening Solution

Plastic rivets are lightweight, durable fasteners used for assembling plastic components, electronics, and automotive parts. Unlike metal rivets, plastic rivets provide non-corrosive, non-conductive fastening solutions.

Advantages of Plastic Rivets:

- Lightweight: Ideal for applications where weight reduction is crucial.

- Corrosion-Resistant: Unlike metal rivets, plastic rivets do not rust.

- Non-Conductive: Suitable for electrical and electronic applications.

- Easy Installation: Snap-fit or push-in designs allow for quick assembly.

Common Applications of Plastic Rivets:

- Automotive Panels: Used to fasten interior and exterior components.

- Electronics Manufacturing: Securely fasten circuit boards and casings.

- Furniture Assembly: Found in modular furniture and lightweight fixtures.

- Consumer Goods: Used in toys, household appliances, and packaging.

What is Overmolding?

Overmolding is an advanced manufacturing process that involves molding one material over another to create a single, unified part. This technique enhances product durability, grip, and aesthetics.

Benefits of Overmolding:

- Enhanced Grip and Comfort: Used in tool handles and medical devices.

- Increased Durability: Provides extra protection against wear and tear.

- Aesthetic Appeal: Creates a seamless and visually appealing product.

- Vibration and Shock Absorption: Reduces noise and enhances performance in industrial applications.

Applications of Overmolding:

- Medical Devices: Soft-touch grips on surgical instruments.

- Power Tools: Rubberized handles for improved grip.

- Automotive Parts: Protective coatings for components exposed to wear.

- Electronics: Protective casings for smartphones and remote controls.

At FirstMold, we provide high-quality overmolding solutions to enhance product performance and durability.

Conclusion

Understanding TPU material, PET, CNC machining, plastic rivets, and overmolding is essential for making informed manufacturing decisions. These materials and processes play a crucial role in various industries, offering durability, flexibility, precision, and efficiency.

At FirstMold, we specialize in providing high-quality manufacturing solutions tailored to our clients' needs. Whether you need precision CNC machining, innovative overmolding, or durable plastic rivets, we are here to help you achieve the best results.

For expert guidance and high-quality manufacturing solutions, visit FirstMold today!

Contact Us

Location:88 Shagang W Rd, Gangkou Town, Zhongshan City 528447, Guangdong, China

Phone+86 13925326660

Email:sales@firstmold.com

Tag - overmolding