Introduction to Custom UV DTF Transfers

In the ever-evolving world of custom printing, custom UV DTF transfers have emerged as a game-changer. Whether you’re a business owner, hobbyist, or professional printer, understanding the potential of UV DTF transfers can open up new opportunities for high-quality, durable, and vibrant printing solutions.

This guide will take you through everything you need to know about custom UV DTF transfers, including their benefits, applications, and the process of creating them.

What Are Custom UV DTF Transfers?

Custom UV DTF (Direct to Film) transfers are an advanced printing technology that utilizes UV-curable inks to create highly detailed, durable, and vibrant designs that can be transferred onto various surfaces. Unlike traditional printing methods, UV DTF transfers do not require heat pressing, making them a convenient and efficient choice.

These transfers consist of two primary components:

UV-Cured Ink Layer: The printed design is cured instantly using ultraviolet (UV) light, resulting in a solid and durable print.

Adhesive Layer: This layer ensures the design adheres to the surface, providing strong bonding without additional heating or pressure.

Benefits of Custom UV DTF Transfers

1. Durability and Longevity

Custom UV DTF transfers offer superior durability compared to traditional heat transfers. They are resistant to water, chemicals, and UV exposure, ensuring that the designs do not fade or peel over time.

2. Vibrant and High-Quality Prints

The UV printing process enables the creation of vivid, high-resolution images with precise details and sharp edges. The colors remain bright and consistent for extended periods.

3. Versatile Application

UV DTF transfers can be applied to a wide range of materials, including plastic, glass, metal, ceramics, wood, and even leather. This versatility makes them ideal for customizing various products like phone cases, tumblers, signs, and promotional items.

4. No Heat Press Required

Unlike traditional DTF or heat transfer vinyl (HTV) methods, UV DTF transfers do not require a heat press. The process is simple, requiring only a peel-and-stick application, making it user-friendly for businesses and individuals alike.

5. Fast Production Time

The UV curing process ensures instant drying, reducing the waiting time and increasing productivity. Businesses can fulfill orders quickly and efficiently.

How to Create Custom UV DTF Transfers

Step 1: Designing the Artwork

Start with a high-resolution digital design. Software like Adobe Illustrator, Photoshop, or CorelDRAW can be used to create vector-based designs for crisp and clear prints.

Step 2: Printing the Design

A specialized UV printer is used to print the design onto a release film. The UV ink is instantly cured using ultraviolet light, creating a strong and durable print.

Step 3: Applying the Adhesive Layer

Once the design is printed, a pressure-sensitive adhesive layer is applied. This ensures the transfer sticks firmly to the intended surface without additional heat or pressure.

Step 4: Cutting and Peeling

The design is then cut into the desired shape, and the excess film is removed, leaving only the intended transfer.

Step 5: Applying the Transfer

Peel the design from the backing film and apply it directly onto the target surface. Press firmly to ensure complete adhesion, and then peel away the transfer film, leaving behind a stunning, high-quality print.

Applications of Custom UV DTF Transfers

1. Personalized Gifts

Create custom mugs, keychains, phone cases, and tumblers with unique designs for gifts and special occasions.

2. Business Branding

Businesses can use UV DTF transfers for branding purposes, such as customizing promotional products, signage, and packaging.

3. Home Decor

Decorate furniture, glassware, and wooden items with UV DTF transfers for a professional, long-lasting look.

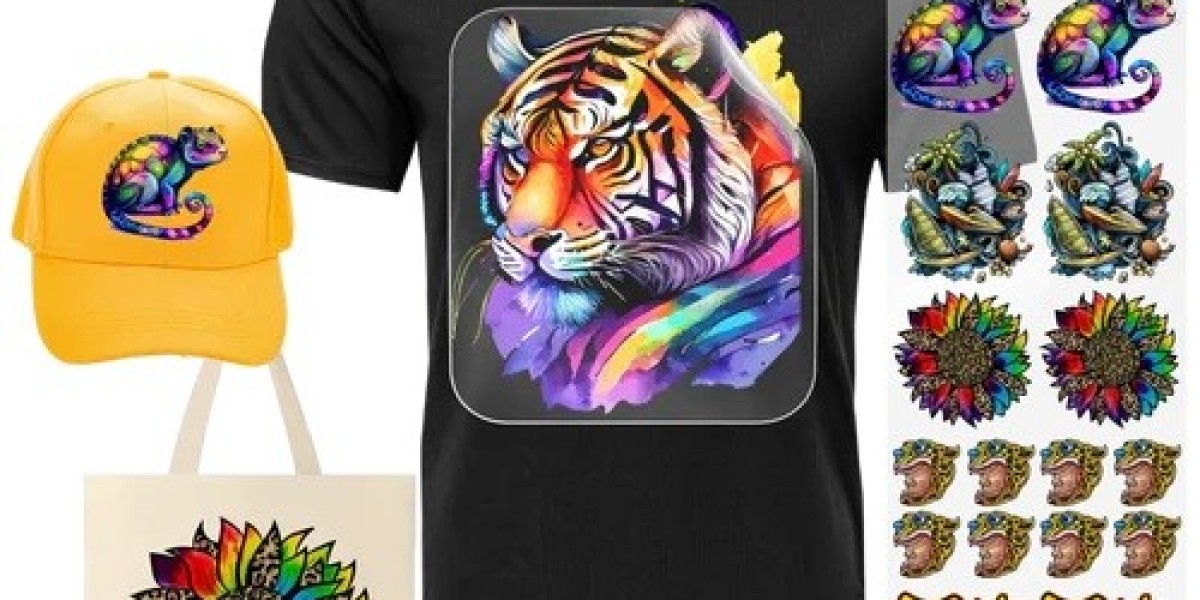

4. Apparel and Accessories

While not ideal for fabrics, UV DTF transfers can be used on items like leather bags, wallets, and shoes.

5. Electronics Customization

Personalize laptops, tablets, gaming consoles, and more with intricate UV DTF designs.

Tips for Achieving the Best Results

Use High-Quality UV Ink: The quality of the ink plays a significant role in durability and vibrancy.

Ensure Proper Surface Preparation: Clean the surface thoroughly before application to remove dust, oil, and debris.

Apply Even Pressure: Press the transfer evenly to avoid bubbles or uneven adhesion.

Store Transfers Properly: Keep them in a cool, dry place to maintain adhesive quality and prevent damage.

Why Choose Custom UV DTF Transfers Over Other Methods?

UV DTF vs. Traditional DTF

Unlike traditional DTF, UV DTF does not require heat pressing, making the process simpler and more efficient.

UV DTF vs. Screen Printing

Screen printing requires extensive setup and is cost-effective only for large-scale production, whereas UV DTF transfers are perfect for small-batch and custom orders.

UV DTF vs. Heat Transfer Vinyl (HTV)

HTV requires heat application and is mainly limited to fabric, whereas UV DTF transfers can be applied to multiple surfaces.

Conclusion

Custom UV DTF transfers are revolutionizing the printing industry with their durability, high quality, and versatile applications. Whether you’re a business looking to expand your product line or a creative individual exploring new customization options, UV DTF transfers offer an efficient and user-friendly solution.

By understanding the process, benefits, and best practices, you can leverage UV DTF technology to create stunning, long-lasting designs for personal or commercial use. Start exploring the possibilities today!

FAQs

1. Are UV DTF transfers waterproof?

Yes! They are highly resistant to water, making them perfect for outdoor and everyday use.

2. Can I apply UV DTF transfers to fabric?

No, UV DTF transfers are not suitable for fabrics. They work best on hard surfaces like glass, plastic, and metal.

3. How long do UV DTF transfers last?

With proper application, they can last for years without fading or peeling.

4. Do I need any special equipment to apply UV DTF transfers?

No, UV DTF transfers are peel-and-stick, eliminating the need for heat presses or special tools.

5. Where can I buy custom UV DTF transfers?

Many online vendors and local printing shops offer custom UV DTF transfer services. Be sure to choose a reputable provider for the best quality results.