Enhance Your PCB Assembly Process with Advanced Solutions

Efficient PCB Cleaning Machines: A Necessity for Quality Assurance

In the world of electronics manufacturing, maintaining the highest standards of cleanliness is crucial for ensuring the performance and longevity of printed circuit boards (PCBs). PCB cleaning machines play a pivotal role in this process. These machines are designed to remove contaminants such as flux residues, dust, and other impurities that can compromise the functionality of the boards. By investing in advanced PCB cleaning machines, manufacturers can significantly improve the quality and reliability of their products.

For those operating in India's capital, finding PCB cleaners in Delhi is essential for maintaining a smooth production line. Delhi is home to numerous suppliers and service providers who specialize in PCB cleaning solutions, offering state-of-the-art machines and expert maintenance services. Whether you're a small-scale manufacturer or a large enterprise, having access to reliable PCB cleaners in Delhi can make a significant difference in your operational efficiency.

The Importance of Conformal Coatings: Acrylic and PU Options

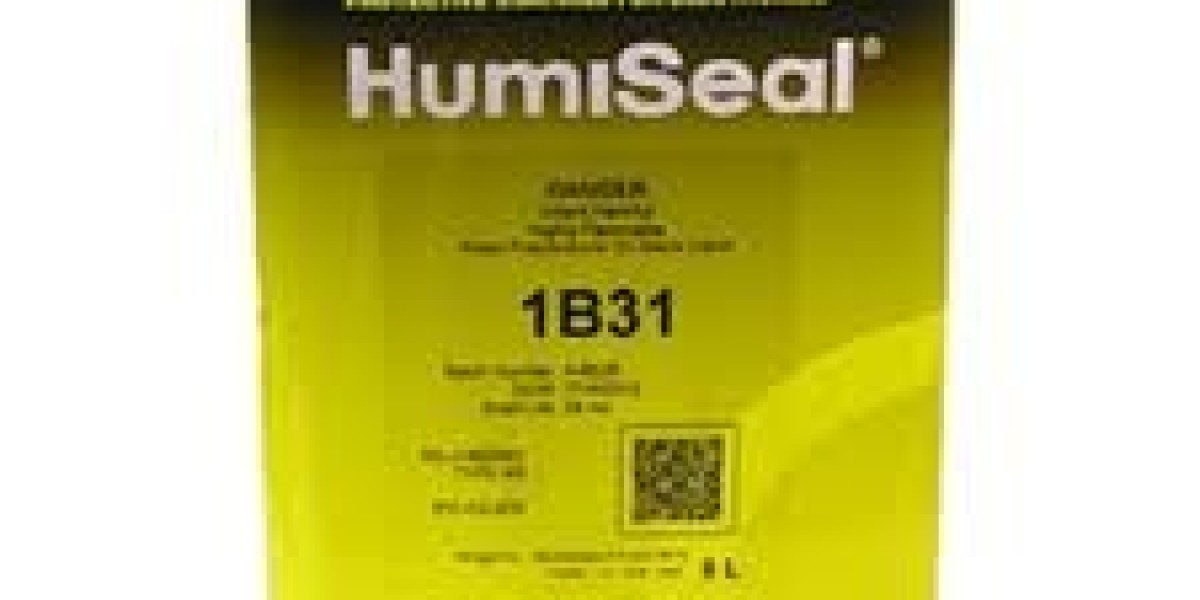

Conformal coatings are essential for protecting PCBs from environmental factors such as moisture, dust, and chemicals. Among the various types of coatings available, Acrylic conformal coating is highly regarded for its excellent dielectric properties and ease of application. This type of coating provides a transparent protective layer that can be easily inspected and repaired if necessary. Acrylic conformal coating is ideal for applications where flexibility and ease of removal are important.

Advanced Dispensing Solutions: Adhesive and Fluid Dispensing Systems

In the realm of electronics assembly, precise dispensing of adhesives and other fluids is critical for achieving optimal results. Adhesive dispensing systems are designed to accurately apply adhesives, sealants, and other materials to specific areas of the PCB. These systems ensure consistent application, reducing waste and improving the overall quality of the assembly process.

One of the most innovative solutions in this field is the robotic dispenser. These automated machines offer unparalleled precision and speed, making them ideal for high-volume production environments. Robotic dispensing machines can handle a wide range of materials and are programmable to meet the specific requirements of different applications. By incorporating robotic dispensers into your assembly line, you can achieve greater efficiency and accuracy in your dispensing processes.

In addition to adhesive dispensing, fluid dispensing systems are essential for applying various liquids, such as solder paste and lubricants, in a controlled manner. These systems include a variety of components, such as dispensing caps, which ensure that the fluid is delivered precisely where it's needed. By utilizing advanced fluid dispensing systems, manufacturers can improve the consistency and quality of their products, reducing the risk of defects and ensuring better performance.

Choosing the Best Electric Screwdrivers for Your Assembly Line

When it comes to assembling electronic components, the choice of tools can significantly impact productivity and quality. Best electric screwdrivers are essential for ensuring that screws are fastened securely and accurately. These tools are designed to provide consistent torque, reducing the risk of over-tightening or under-tightening screws, which can lead to damage or poor connections.

Investing in the best electric screwdriver can streamline your assembly process and improve the overall quality of your products. Look for features such as adjustable torque settings, ergonomic design, and long battery life to ensure that your electric screwdriver meets the demands of your production environment. By choosing high-quality electric screwdrivers, you can enhance the efficiency and reliability of your assembly operations, leading to better outcomes and higher customer satisfaction.

Conclusion

Incorporating advanced solutions such as PCB cleaning machines, Acrylic conformal coatings, PU conformal coatings, adhesive dispensing systems, robotic dispensers, and the best electric screwdrivers into your electronics assembly process can significantly improve the quality and reliability of your products. By staying ahead of the curve and investing in the latest technologies, you can ensure that your manufacturing operations remain efficient, precise, and competitive in the ever-evolving electronics industry. Whether you're sourcing PCB cleaners in Delhi or upgrading your dispensing systems, these advancements will help you achieve superior results and maintain a high standard of excellence. Visit here - https://mectronics.in/