In an increasingly automated world, industries are shifting toward smarter, more reliable systems that can adapt to changing demands. At the heart of this transformation lie Customized PLC Control Solutions—intelligent automation systems tailored to meet specific operational needs. Coupled with protective gear like the IP55 Electrical Enclosure, these systems offer powerful, flexible, and resilient control for a wide range of industrial applications.

What Are Customized PLC Control Solutions?

Programmable Logic Controllers (PLCs) are digital computers used for industrial automation, specifically to control machinery, processes, and factory assembly lines. While standard PLC systems serve general purposes, customized PLC control solutions are engineered to address unique workflows, equipment configurations, and environmental conditions.

These tailor-made systems integrate specialized logic programming, hardware interfaces, and modular design to ensure seamless functionality with your existing infrastructure. Whether managing a high-speed conveyor or coordinating a multi-axis robotic arm, custom PLC solutions give you precision, adaptability, and control.

Key Features of Customized PLC Control Solutions

Tailored Logic Programming

Customized PLCs use purpose-built software logic to execute specific sequences based on your unique operational requirements. This reduces cycle time and enhances performance.Advanced Communication Capabilities

Modern PLCs support protocols like Modbus, Ethernet/IP, and Profibus. Customized systems ensure compatibility with SCADA systems, HMIs, IoT sensors, and cloud-based platforms.Real-Time Monitoring and Diagnostics

Real-time data logging and remote monitoring features help in predictive maintenance, fault detection, and process optimization—driving efficiency and reducing downtime.Scalable Architecture

Customized PLC systems allow for future upgrades. You can easily add new modules, control more equipment, or integrate with advanced analytics platforms.Enhanced Safety and Compliance

Industry-specific safety features, such as emergency stop logic, interlock control, and fail-safe mechanisms, can be integrated to meet ISO, OSHA, or CE compliance standards.

Why IP55 Electrical Enclosures Are Essential

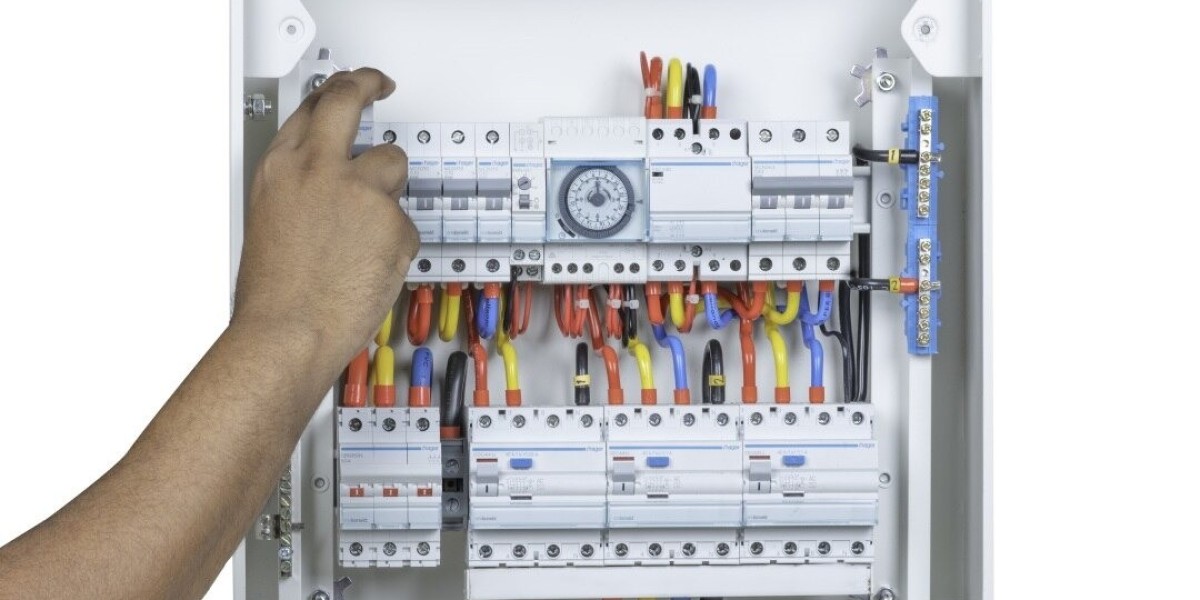

Custom PLC systems often operate in challenging environments—factories with dust, humidity, or liquid exposure. To protect these vital control units, the use of IP-rated enclosures is crucial. An IP55 Electrical Enclosure offers robust protection for sensitive electronic components.

What Does IP55 Mean?

The first digit "5" means limited protection against dust ingress.

The second digit "5" indicates protection against water jets from any direction.

Benefits of Using IP55 Electrical Enclosures:

Environmental Protection: Safeguards PLCs from moisture, dust, and debris.

Increased Longevity: Reduces the risk of component failure, extending the lifespan of the system.

Heat Management: Many enclosures support fans or ventilation systems for cooling.

Versatility: Available in wall-mounted, floor-standing, or compact designs for space optimization.

Applications Across Industries

Food and Beverage Processing

Hygiene and consistency are key. Custom PLC systems automate pasteurization, packaging, and cleaning-in-place (CIP) systems, all protected within IP55 enclosures for sanitary safety.Pharmaceutical Manufacturing

Precision in dosing, mixing, and packaging is vital. Customized PLCs handle these tasks while maintaining compliance with regulatory standards.Water and Wastewater Treatment

Custom logic controls pump stations, chemical dosing, and filtration units. IP55 enclosures ensure protection against wet and corrosive environments.Energy and Utilities

In energy plants, customized PLCs control generators, turbines, and switchgear. IP-rated enclosures protect controls in both indoor and outdoor installations.Automotive Assembly

Robotic arms, welding machines, and conveyors are synchronized using tailor-made PLC programs. Enclosures ensure reliable performance under heat and vibration.

Choosing the Right Partner for Customized PLC Solutions

To maximize your return on investment, it’s important to collaborate with an experienced automation provider. Look for these qualities:

Proven industry expertise

Capability to design, build, program, and test in-house

Integration support with your existing systems

Provision of IP55 (or higher) enclosure solutions

Post-installation service and support

Conclusion

Customized PLC control solutions are revolutionizing industrial automation by offering flexibility, performance, and resilience tailored to specific operations. When housed within an IP55 Electrical Enclosure, these systems become even more robust—ready to handle the rigors of real-world applications.

If you’re aiming for smarter automation, increased uptime, and greater control, investing in a custom PLC solution is a strategic move toward operational excellence.

Ready to future-proof your operations? Explore how customized PLC control systems combined with IP55-rated protection can transform your production capabilities.