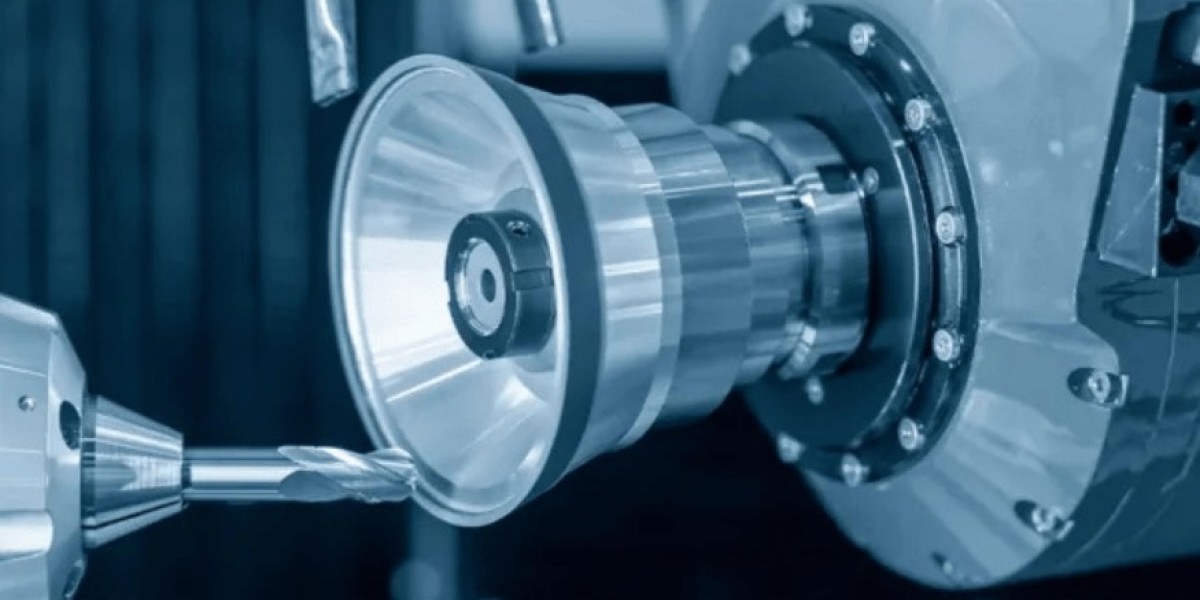

For industries seeking accuracy, repeatability, and high-quality production, CNC machining has become an essential part of modern manufacturing. At EliteMoldTech, we specialize in delivering exceptional results through our CNC Machining Service. From prototyping to full-scale production, our solutions are designed to meet the strictest engineering requirements for components used across sectors like automotive, aerospace, medical, and industrial equipment. This article will explore what CNC machining service entails, its advantages, key applications, and what to consider when choosing a service provider.

What Is CNC Machining Service?

CNC (Computer Numerical Control) machining is an automated manufacturing process that uses computer-controlled tools to remove material from a solid block (known as a blank or workpiece). These machines follow coded instructions to produce parts with high dimensional accuracy and consistency. CNC machining includes a range of techniques such as milling, turning, drilling, and grinding.

With the right setup, CNC machines can handle both simple and highly complex geometries, making them suitable for a wide range of applications across multiple industries.

Advantages of CNC Machining Service

Investing in a CNC machining service offers significant operational and commercial benefits. Here are some of the most important ones:

1. Superior Precision and Accuracy

CNC machines are capable of maintaining tight tolerances. This makes them ideal for parts where accuracy is non-negotiable, such as engine components, surgical devices, or high-performance industrial tools.

2. Repeatability

Once a design is programmed, the same part can be produced over and over again with minimal variation. This makes CNC machining extremely reliable for both low- and high-volume production.

3. Faster Production Timelines

Because CNC machining is automated, it significantly reduces production time compared to manual methods. Complex parts that might take hours to machine manually can be produced in minutes with CNC.

4. Material Versatility

CNC machines are compatible with a wide variety of materials including metals (aluminum, steel, titanium), plastics (ABS, PEEK), composites, and more. This flexibility makes the process suitable for a broad range of product requirements.

5. Cost-Effective for Short and Medium Runs

While CNC machining may require upfront costs for programming and setup, it becomes highly economical when producing batches or prototypes. There’s minimal material waste, and the automation reduces labor costs.

Common CNC Machining Techniques

To understand the scope of CNC machining services, it's important to know the common processes involved:

CNC Milling

In this method, rotating cutters remove material from a stationary workpiece. It’s used to produce complex 3D shapes and surfaces and is ideal for both flat and irregular geometries.

CNC Turning

CNC turning involves rotating the workpiece while a stationary cutting tool shapes it. This technique is typically used for cylindrical or conical parts such as shafts, bolts, and bushings.

CNC Drilling

This process is used for creating precise holes in the material. CNC drilling machines offer high accuracy and are frequently used alongside milling and turning for complex parts.

CNC Grinding

Grinding is applied when high surface finish or exact dimension control is needed. CNC grinding machines use abrasive wheels and are suitable for extremely hard materials or very fine finishing.

Industries That Rely on CNC Machining Service

Automotive

Precision components like pistons, gears, and engine housings are machined with high consistency and strength, enabling manufacturers to meet safety and performance standards.

Aerospace

Aircraft components demand ultra-tight tolerances and reliability. CNC machining is critical for producing airframe structures, turbine blades, and other flight-critical parts.

Medical

Surgical tools, implants, and diagnostic equipment require bio-safe materials and microscopic accuracy. CNC machining allows manufacturers to achieve the required finish and quality.

Industrial Machinery

Heavy equipment and custom tools are produced using CNC to ensure durability, alignment, and compatibility with demanding operational environments.

Electronics

With the rise in miniaturized components, CNC machining supports the production of heat sinks, enclosures, and connection elements with high accuracy.

CNC Machining Service Workflow

Here is a simplified breakdown of the CNC machining service process:

Design and Programming

The process begins with a CAD (Computer-Aided Design) model. This digital file is then translated into machine-readable instructions using CAM (Computer-Aided Manufacturing) software.

Material Selection and Preparation

Based on the design, appropriate raw materials are selected. The workpiece is then mounted onto the machine bed or spindle.

Machining Execution

CNC machines follow the programmed toolpath to cut, drill, or shape the part. Multi-axis machines may handle multiple operations in one cycle.

Inspection and Quality Control

Dimensional checks, surface finish evaluations, and other quality controls are conducted to ensure the part meets specifications.

Post-Processing and Delivery

Depending on the requirement, additional operations such as deburring, polishing, or coating may be performed before the parts are packed and shipped.

Choosing the Right CNC Machining Service Provider

When selecting a CNC machining partner, consider the following factors:

Technical Capabilities: Ensure the provider offers multi-axis machining, CAD/CAM support, and modern equipment.

Material Expertise: Look for experience in machining a variety of metals and plastics relevant to your product.

Quality Standards: Check for certifications like ISO 9001, as well as in-house quality assurance protocols.

Lead Time and Scalability: The provider should be able to deliver on time and scale production as needed.

Customer Support: A responsive service team can help you refine your designs, reduce costs, and ensure successful outcomes.

Why Choose EliteMoldTech for CNC Machining Service?

At EliteMoldTech, our CNC machining capabilities are designed to support high-precision, on-demand manufacturing. Our advanced multi-axis machines, coupled with experienced engineers and rigorous quality control, allow us to handle everything from rapid prototyping to high-volume production. We also provide guidance on material selection, cost optimization, and design improvements to maximize manufacturing success.

Whether you’re launching a new product, refining an existing design, or scaling production, EliteMoldTech offers the CNC machining service you can trust to deliver excellence.