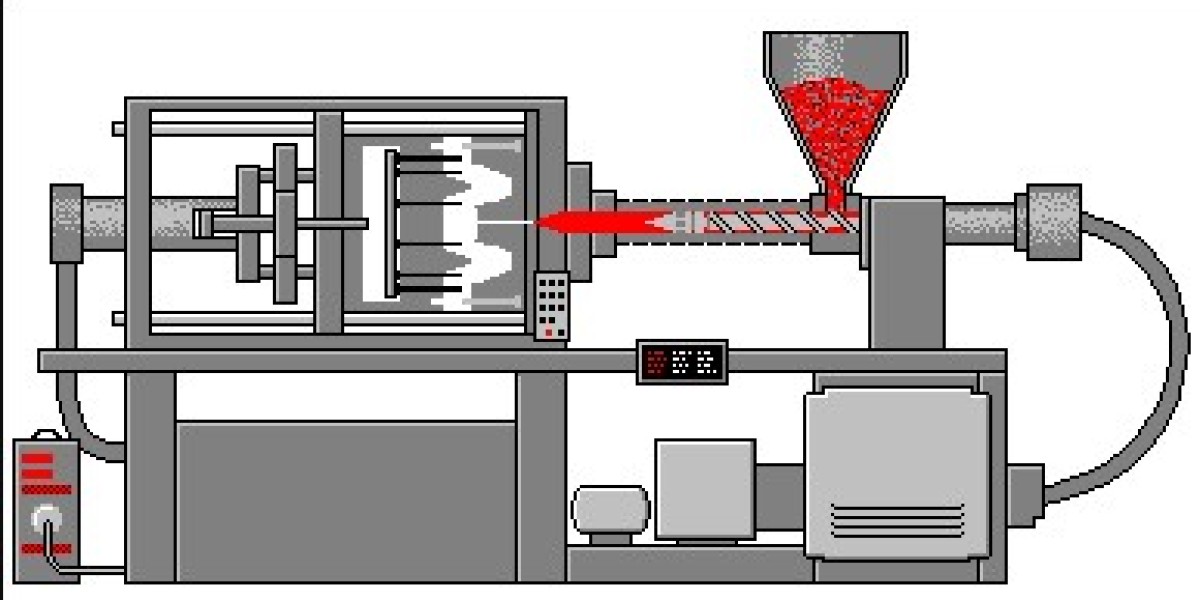

When it comes to custom manufacturing solutions, plastic injection molding services offer a versatile and cost-effective option for producing a wide range of plastic parts and products. This process involves injecting molten plastic material into a mold cavity, allowing it to cool and harden into the desired shape. With the ability to create intricate and complex designs, plastic injection molding is widely used in various industries such as automotive, consumer goods, medical devices, and more.

One of the key advantages of plastic injection molding services is the ability to create custom-made parts with precision and consistency. By using computer-aided design (CAD) software and advanced machinery, manufacturers can produce high-quality plastic components that meet specific requirements and standards. This level of customization allows businesses to develop unique products that cater to their target market's needs and preferences.

Moreover, plastic injection molding services offer fast turnaround times, making it an efficient solution for mass production. Once the mold is created and the production process is set up, manufacturers can produce a large volume of parts in a relatively short period. This not only helps reduce lead times but also ensures a steady supply of products to meet market demand.

In addition to speed and accuracy, plastic injection molding services also offer cost-effective solutions for businesses. By using automated processes and advanced technologies, manufacturers can optimize production efficiency and minimize material waste. This results in lower production costs, which can translate to competitive pricing for the end products.

Furthermore, plastic injection molding services are environmentally friendly as they enable the recycling of plastic materials. By reusing and repurposing plastic materials, manufacturers can reduce their carbon footprint and contribute to a more sustainable manufacturing process. This eco-friendly approach is becoming increasingly important in today's business landscape, where sustainability and environmental responsibility are key priorities.

Another benefit of plastic injection molding services is the ability to create durable and long-lasting products. With the use of high-quality materials and advanced production techniques, manufacturers can produce plastic parts that are resistant to wear and tear, corrosion, and impact. This makes them ideal for use in demanding applications where strength and durability are essential.

When it comes to choosing a plastic injection molding service provider, it is essential to look for a reputable company with a proven track record of delivering high-quality products. By partnering with an experienced manufacturer, businesses can benefit from expertise, reliability, and superior customer service. Additionally, working with a trusted partner can ensure that the production process runs smoothly and efficiently, from design and prototyping to final product delivery.

Overall, plastic injection molding services offer a wide range of benefits for businesses looking to develop custom-manufactured products. With their precision, speed, cost-effectiveness, and sustainability, plastic injection molding services are a valuable solution for companies seeking to meet market demand and drive business growth. By leveraging the advantages of plastic injection molding, businesses can achieve success in today's competitive marketplace.