In the world of custom printing, innovation is key. One of the most advanced techniques taking over the industry is custom UV DTF transfers. Whether you're a business looking for high-quality branding solutions or a creative individual wanting to personalize products, UV DTF (Direct to Film) transfers offer unparalleled durability, color vibrancy, and versatility.

But what exactly are custom UV DTF transfers, and why are they becoming so popular? This article will cover everything you need to know, from their benefits to application methods, ensuring you make the most of this revolutionary printing technique.

What Are Custom UV DTF Transfers?

UV DTF (Ultra Violet Direct to Film) transfers are a specialized printing technology that allows users to apply high-quality, full-color designs onto a variety of surfaces, including:

- Glass

- Wood

- Metal

- Acrylic

- Plastic

- Leather

- Tumblers and more

Unlike traditional heat transfer vinyl or screen printing, UV DTF transfers do not require heat pressing. Instead, they use UV-cured ink and adhesive to create a peel-and-stick decal that adheres firmly to surfaces, making them an excellent choice for hard substrates.

How Do UV DTF Transfers Work?

The process of creating custom UV DTF transfers involves several steps to ensure precision and longevity. Here’s a breakdown:

1. Printing the Design

The design is printed onto a specialized film using UV-curable ink. These inks are cured instantly using UV light, ensuring they remain vibrant and durable.

2. Applying Adhesive

A clear adhesive layer is added over the printed design, which helps in transferring the artwork onto the desired surface.

3. Transfer and Application

Once printed and adhesive-backed, the transfer is peeled and placed onto the target surface, requiring only slight pressure for adherence. Unlike heat transfers, no heat press is required, making this method much more versatile.

4. Curing and Final Touches

After application, the UV-cured inks provide a scratch-resistant, waterproof, and long-lasting finish, ensuring that the design remains intact over time.

Why Choose Custom UV DTF Transfers?

1. No Heat Press Required

Unlike traditional heat transfer vinyl (HTV) or sublimation, UV DTF transfers work without heat. This makes them perfect for delicate materials that can’t withstand high temperatures.

2. Superior Durability

UV-cured inks are resistant to scratches, water, and environmental factors, making custom UV DTF transfers ideal for long-term use.

3. High-Resolution and Vibrant Colors

Since these transfers use UV-curable inks, they produce rich, vibrant, and high-resolution images with precise detailing. This ensures that designs look professional and eye-catching.

4. Works on Hard Surfaces

While most traditional transfer methods are limited to fabric, UV DTF transfers can be applied to hard and non-porous surfaces like glass, acrylic, wood, and plastic. This opens up endless possibilities for product customization.

5. Easy Application Process

The peel-and-stick nature of UV DTF transfers makes them extremely easy to apply. There’s no need for expensive machinery, making this method accessible to beginners and professionals alike.

6. No Weeding or Masking Required

Unlike vinyl decals that require tedious weeding and masking, custom UV DTF transfers come ready to apply, saving time and effort.

Applications of Custom UV DTF Transfers

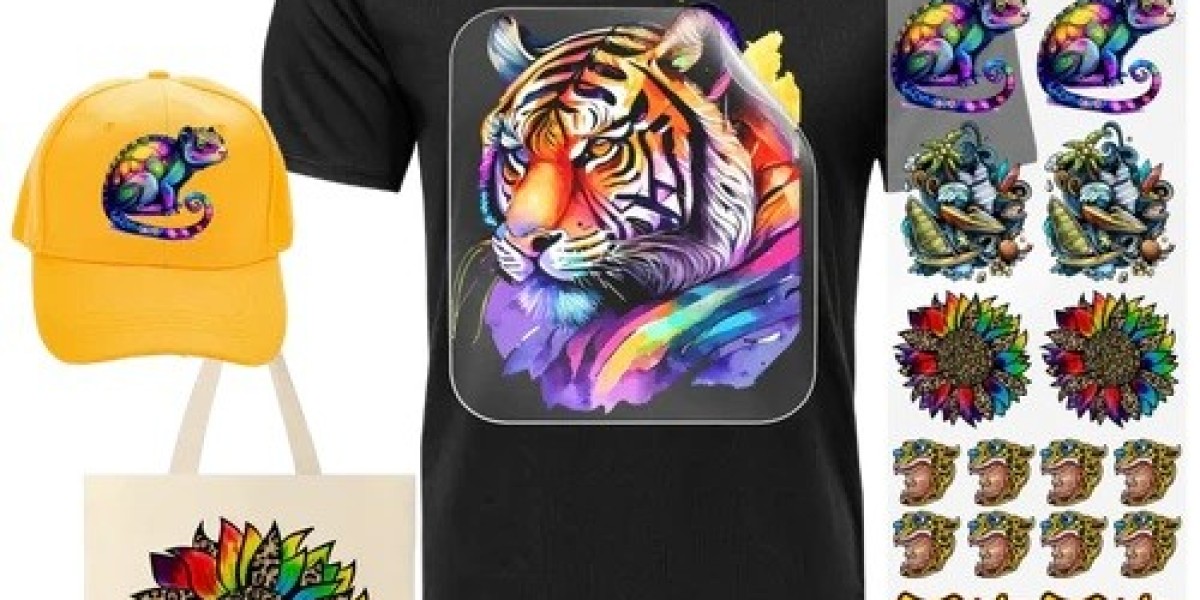

Due to their versatility, custom UV DTF transfers are widely used in various industries. Here are some of the most popular applications:

1. Custom Tumblers and Drinkware

Personalized tumblers, mugs, and bottles are in high demand. UV DTF transfers allow creators to apply detailed, full-color designs to drinkware without worrying about fading or peeling.

2. Signage and Branding

Businesses can use UV DTF transfers to create eye-catching signs, logos, and promotional materials for storefronts, displays, and office spaces.

3. Personal Gifts and Accessories

From keychains to phone cases, UV DTF transfers help customize gifts with intricate designs, names, and messages that last.

4. Home Decor

Glass panels, picture frames, and acrylic decorations can be easily customized using UV DTF printing, making them ideal for personalized interior design.

5. Industrial and Promotional Items

UV DTF transfers are also widely used in corporate giveaways, product branding, and merchandise production. Their durability ensures that brand logos remain intact, even with heavy usage.

How to Apply Custom UV DTF Transfers Like a Pro

Step 1: Clean the Surface

Ensure the target surface is clean and dry. Use alcohol wipes to remove dust, oil, and debris for optimal adhesion.

Step 2: Peel the Transfer

Carefully peel the backing film from the transfer. Be gentle to avoid damaging the design.

Step 3: Place and Press

Position the transfer on the surface and apply gentle pressure. Use a squeegee or your fingers to smooth out air bubbles.

Step 4: Remove the Clear Film

After securing the transfer, slowly peel away the top film, leaving behind a perfectly applied design.

Step 5: Let It Cure

Although UV DTF transfers don’t require heat, allowing them to sit for a few hours ensures maximum adhesion and longevity.

Where to Buy Custom UV DTF Transfers?

If you’re looking for high-quality custom UV DTF transfers, many online and local print shops offer customizable options. Some popular sources include:

- Etsy – Ideal for small businesses and DIY crafters.

- Amazon – Offers pre-made and customizable UV DTF transfer sheets.

- Specialized Print Shops – Many printing companies now offer custom UV DTF printing services tailored to business and personal needs.

Conclusion

Custom UV DTF transfers are revolutionizing the printing industry, providing a versatile, durable, and vibrant solution for customizing hard surfaces. Whether you're a small business owner, artist, or DIY enthusiast, UV DTF printing offers limitless possibilities for creating high-quality, long-lasting designs.

With no heat press required, easy application, and stunning color quality, custom UV DTF transfers are the perfect choice for modern printing needs. Start exploring this innovative printing technique today and elevate your customization projects to the next level!

FAQs

1. Are UV DTF transfers waterproof?

Yes! UV DTF transfers are waterproof, scratch-resistant, and highly durable, making them ideal for items exposed to moisture.

2. Can I use UV DTF transfers on fabric?

No, UV DTF transfers are specifically designed for hard surfaces like glass, metal, and plastic. For fabric applications, other methods like sublimation or HTV are better suited.

3. How long do UV DTF transfers last?

With proper application, UV DTF transfers can last for years, thanks to their UV-cured ink technology.

4. Can I create my own custom UV DTF transfers at home?

Yes! If you have a UV printer and DTF film, you can create your own custom UV DTF transfers. However, many print shops offer affordable custom printing services.

5. Do UV DTF transfers require any special equipment?

No, they are peel-and-stick transfers, requiring no heat press or additional tools—just a clean surface for application.

Would you like me to tweak the content further or add more details? ?