Metal on metal brakes are a type of brake system commonly used in vehicles. As the name suggests, these brakes use metal components to generate friction and slow down or stop a vehicle. The system consists of a brake pad and a rotor that press against each other to create the necessary friction.

Metal on metal brakes have several advantages over other types of brake systems. They are known for their durability and long lifespan, making them a popular choice for heavy-duty vehicles and high-performance cars. Additionally, metal on metal brakes are less likely to fade or lose effectiveness over time, which can be a safety concern with other brake systems. However, they can also be louder and produce more dust than other types of brakes, which can be a drawback for some drivers.

Fundamentals of Metal on Metal Brakes

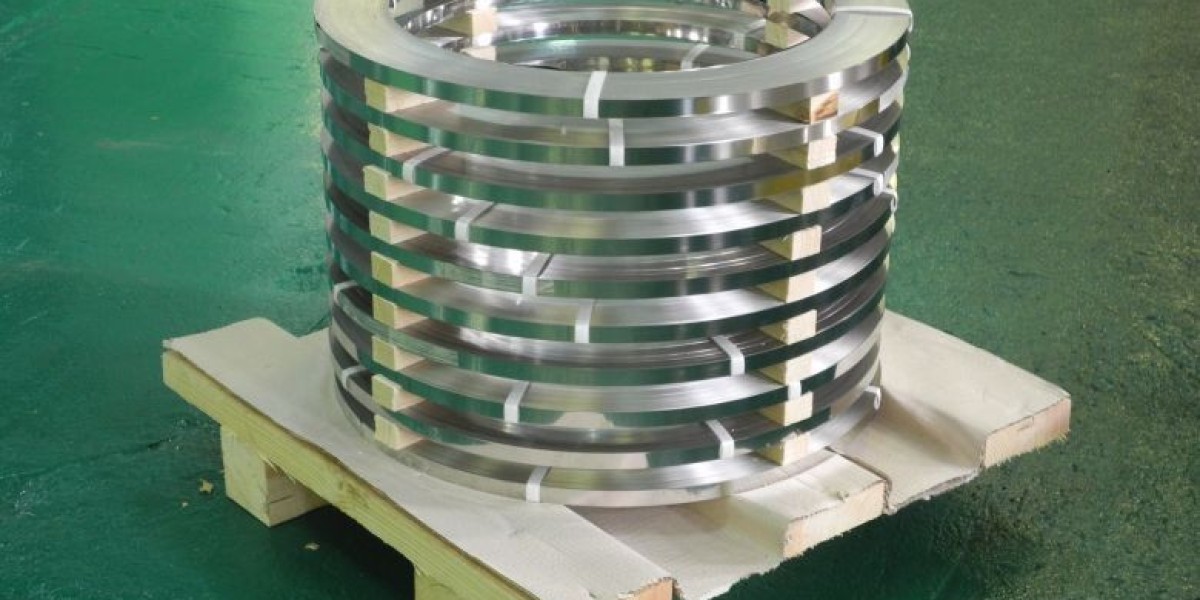

Composition and Materials

Metal on metal brakes are composed of two metal components that come into contact with each other during braking. The metal materials used in these brakes are typically a combination of iron, copper, and other metals such as titanium and cobalt. The metal components are often referred to as the rotor and the brake pad. The rotor is attached to the wheel and rotates with it, while the brake pad is stationary and presses against the rotor to create friction and slow down the vehicle.

Design and Mechanism

The design of metal on metal brakes is relatively simple compared to other types of brakes. The brake pad is designed to fit snugly against the rotor, creating a large surface area for friction to occur. When the driver presses the brake pedal, hydraulic pressure is applied to the brake caliper, which in turn squeezes the brake pads against the rotor. This creates the friction necessary to slow down the vehicle.

Advantages Over Other Types

Metal on metal brakes are known for their durability and long lifespan. They are less prone to wear and tear than other types of brakes, such as ceramic brakes, and are better suited for heavy-duty applications. Metal on metal brakes also perform better at high temperatures, making them ideal for high-performance vehicles that require frequent braking. Additionally, metal on metal brakes are generally more affordable than other types of brakes, making them a popular choice for budget-conscious drivers.

In summary, metal on metal brakes are a reliable and cost-effective option for drivers who prioritize durability and performance. With their simple design and high-temperature performance, they are well-suited for heavy-duty applications and high-performance vehicles.

Issues and Maintenance

Wear and Tear

Metal on metal brakes are known for their durability and long-lasting performance. However, they are not immune to wear and tear. Over time, the friction between the brake pads and rotors can cause the pads to wear down, reducing their effectiveness. This can lead to longer stopping distances and decreased safety on the road.

To prevent excessive wear and tear, it is important to regularly inspect the brake pads and rotors for signs of damage or wear. If the brake pads are worn down beyond their recommended thickness, they must be replaced immediately to ensure safe driving conditions.

Noise Concerns

One of the most common complaints about metal on metal brakes is the noise they produce. The high-pitched squealing sound can be a nuisance to drivers and passengers alike. However, not all noise is a cause for concern.

Some noise is normal for metal on metal brakes, especially during the break-in period. However, excessive noise can be a sign of worn or damaged brake pads or rotors. To reduce noise, it is recommended to use brake pads with noise-reducing features and to regularly inspect and replace worn brake components.

Maintenance Practices

Proper maintenance is key to ensuring the longevity and performance of metal on metal brakes. Regularly inspecting and replacing worn brake components is essential to maintaining safe driving conditions.

In addition, it is important to follow the manufacturer's recommended maintenance schedule and use high-quality brake components. This includes using the correct type of brake fluid and avoiding harsh driving conditions that can cause excessive wear and tear on the brakes.

By following these maintenance practices, drivers can ensure the safe and reliable performance of their metal on metal brakes for years to come.