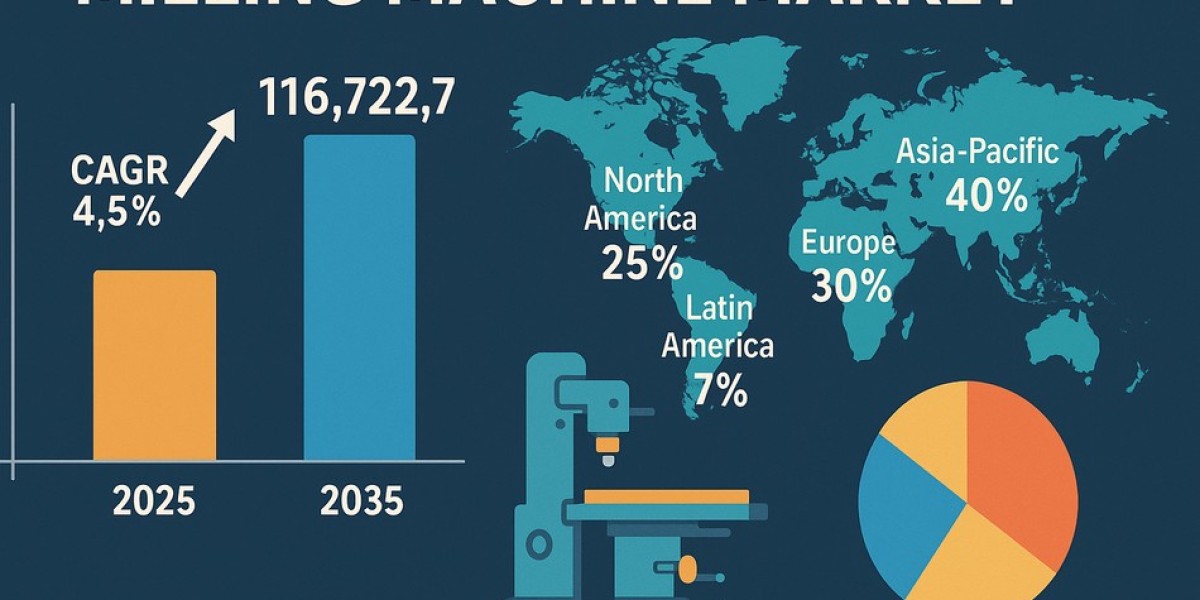

The global milling machine market is set to experience a significant transformation between 2025 and 2035, growing from USD 75,161 million in 2025 to USD 116,722.7 million by 2035, expanding at a CAGR of 4.5%. As manufacturing industries undergo digital evolution, the demand for precision machining solutions continues to surge.

Milling machines are indispensable across sectors such as automotive, aerospace, electronics, medical devices, and general manufacturing. These machines are used to shape materials like metal, wood, and plastic with high accuracy. As the market continues to embrace innovation, newer technologies like Computer Numerical Control (CNC), 5-axis machining, and IoT-enabled systems are reshaping operational standards.

North America is expected to hold a significant share of the global milling machine market. The region, especially the United States, is witnessing widespread adoption of automated milling technologies in industries such as aerospace, automotive, and healthcare. The growing integration of Industry 4.0 principles and smart factory solutions in the region further fuels this demand.

With technological enhancements improving performance and efficiency, milling machines are evolving from traditional standalone units into fully integrated, data-driven assets of smart manufacturing floors.

Gain Valuable Insights from Industry Experts to Shape Your Growth Strategies. Access our Sample Report Now: https://www.futuremarketinsights.com/reports/sample/rep-gb-16589

Report Coverage & Deliverables

The report delivers an in-depth analysis of the global milling machine market, covering key trends, growth drivers, market restraints, competitive landscape, and future opportunities. It provides a regional breakdown, market sizing for the period 2025–2035, CAGR analysis, and company profiles. Additionally, the study includes technological innovation insights, policy impacts, and demand forecasts segmented by end-user industries.

Key Factors Shaping Market Dynamics

The rising demand for high-precision machining, automation in production processes, and technological upgrades in milling systems such as multi-axis CNC and smart milling solutions are the major factors propelling market growth.

High Initial Cost and Skill Gap

One of the notable challenges hindering market expansion is the high initial cost associated with advanced milling machines. Small and medium enterprises (SMEs), in particular, face budget constraints when it comes to upgrading or investing in smart CNC systems.

In parallel, the market is impacted by a skill gap in handling complex, automated systems. While newer machines offer precision and speed, they also demand trained operators familiar with CAD/CAM software and IoT analytics. This lack of expertise can limit the full potential of the technology.

Automation, IoT Integration, and Customization

Modern milling machines are increasingly equipped with sensors, real-time monitoring capabilities, and remote diagnostics, which help streamline operations and reduce downtime. Integration with IoT networks enhances operational efficiency and predictive maintenance.

Moreover, manufacturers are focusing on customizable milling machines tailored for specific industry needs. From dental component manufacturing to heavy-duty aerospace machining, end-users are demanding machines that offer both precision and adaptability.

Precision at its Core – Milling Machines that Shape Industries

Precision is the defining trait of modern milling machines. Whether crafting a lightweight automotive part or a complex aerospace component, these machines deliver accurate results with minimal errors.

Their ability to consistently meet strict tolerance levels has positioned them as the backbone of high-performance manufacturing operations across the globe.

Key Takeaways

From automation to digitization, the milling machine market is undergoing rapid transformation. With strong regional demand, especially in North America and East Asia, the sector is set to benefit from increased investments in smart manufacturing. Continued R&D, the emergence of compact yet powerful machines, and emphasis on customization are expected to shape the future of milling technologies.

Elevate Metalworking with High-Performance Milling Solutions

New-generation milling machines are equipped to deliver high-speed cutting, superior surface finishes, and enhanced durability. These high-performance solutions are becoming the go-to choice for industries requiring dependable and repeatable machining.

Industrial automation, energy efficiency, and multi-material compatibility make today’s machines essential tools for manufacturers aiming to stay competitive in a globalized market.

Where Accuracy Meets Durability – The Milling Machine Advantage

Modern milling machines combine structural rigidity with high-speed capabilities, ensuring accuracy over long production cycles. This results in minimized material wastage and maximized throughput.

Their capacity to handle varying workloads and materials—ranging from soft plastics to hardened metals—positions them as versatile assets in modern production lines.

Designed for Heavy-Duty Machining and Flawless Finish

Robust frame construction, advanced spindle technology, and high-torque drives enable machines to perform heavy-duty tasks while maintaining a flawless finish.

Applications in aerospace and automotive manufacturing especially benefit from these machines, which can mill complex geometries while ensuring surface uniformity and dimensional accuracy.

Milling Machine Market Key Players and Their Information

- DMG Mori Co., Ltd. – A global leader in advanced manufacturing solutions, offering innovative CNC milling machines with IoT integration.

- Haas Automation, Inc. – Renowned for affordable and user-friendly CNC milling machines widely used in educational and industrial sectors.

- Mazak Corporation – Known for high-performance vertical and horizontal milling centers, specializing in multi-tasking machines.

- Hurco Companies, Inc. – Offers intelligent CNC systems that improve job shop efficiency with intuitive controls and real-time feedback.

- Fadal Engineering, Inc. – Focuses on durable vertical machining centers designed for high-volume metalworking applications.

Cut Downtime, Not Corners – Invest in Efficient Milling Technology

Reducing machine downtime is critical in today’s competitive production landscape. Advanced milling machines now come with self-diagnostic capabilities and predictive maintenance features.

By minimizing operational interruptions and increasing machine uptime, manufacturers can improve overall productivity while maintaining quality standards.

Milling Machine Industry Analysis by Type, Automation Level, and End Use Industry

By Product:

- Vertical Mills

- Horizontal Mills

By Application:

- Automotive

- General Machinery

- Precision Engineering

- Transport Machinery

- Others

By Distribution Channel:

- Online

- Offline