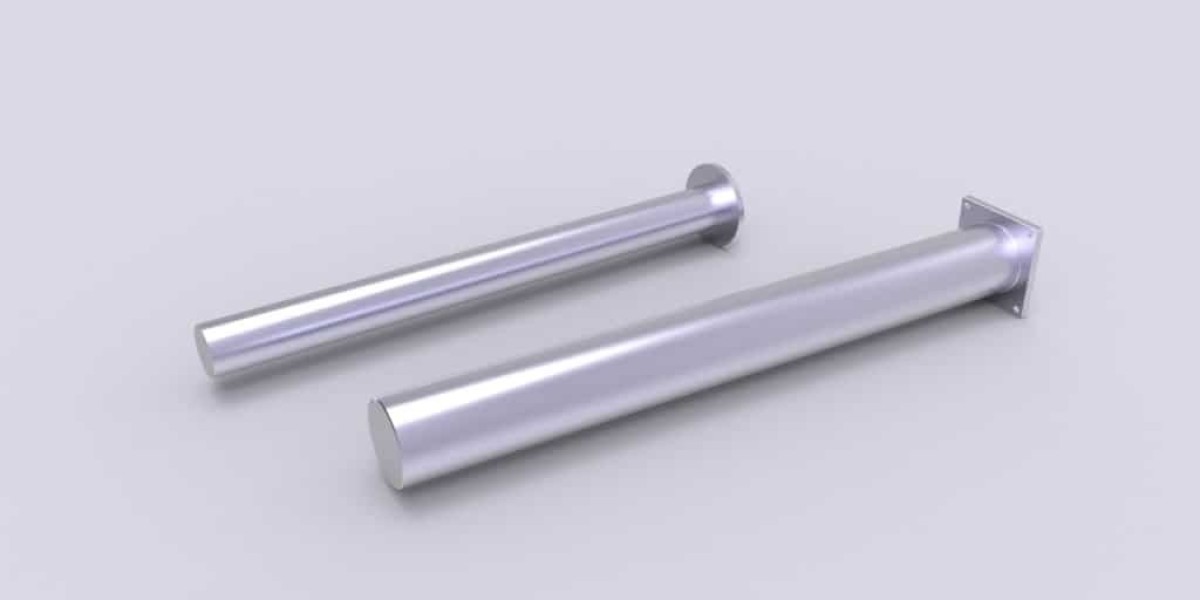

Efficiency comes first in industrial heat procedures with an aim to raise the productivity level, save on energy usage, and be safe. One of the greatest ways through which one could obtain such a demand is by using Heat radiation tubes. Radiant tubes, made from high-temperature alloys like iron-chromium-aluminium and nickel-based alloys, offer a number of benefits that make them essential in many industries. Let us learn why Heat radiation tubes enhance the efficiency of heating systems and how they are also an option for extreme environments.

1. Increased Heat Distribution

Direct heat transfer tubes provide for even heat transfer, which is crucial for those applications that require even and uniform heating. Heat-emitting tubes are designed to release heat directly onto the target surface, thus ensuring heat is applied where it is most needed.

Correct Heating: The radiant tubes radiate heat directly to the workpiece rather than waste in the surrounding area. This targeted heating saves wastage and avoids wastage of energy in dead space.

Enhanced Control: The temperature regulation of a heating or furnace system using Heat radiation tubes is easier to obtain to enable processes such as heat treatment, melting, or curing to be performed under conditions of maximum advantage.

2. High-Temperature Capability

Heat radiation tubes are specially manufactured to withstand high temperatures and thus are more suitable for use in industries that have high heat requirements. They can be used up to temperatures of 1100°C, and when combined with bundle rod heaters, they can go up to 1400°C.

Long-Term Alloys: The alloys that are used for the production of Heat-emitting tubes, i.e., heat-resistant casting alloys and nickel-based alloys, are made such that they can remain in good working condition even under high-temperature exposure. This means less part replacement and maintenance costs.

Longer Lifespan: Since they can resist high temperatures and demanding conditions, radiant tubes can live longer than other heating units, eliminating the need for frequent repairs or replacements.

3. Enhanced Energy Efficiency

One of the most attractive aspects of Heat-emitting tubes is how they can enhance energy efficiency in industrial heating processes. Because Heat radiation tubes emit heat directly to the target, less heat is lost in the process, i.e., energy consumption is optimized.

Lower Energy Bills: Since radiant tubes focus heat where it will be utilized, they reduce the amount of energy needed to produce high temperatures, leading to significant energy savings.

Decreased Operational Cost: With less wasted energy, companies will have their heating bill lowered, thus reducing operational costs in the long run.

4. Versatility in Industrial Applications

Radiant tubes find applications in a vast array of industries and uses due to their flexibility and capacity to operate under harsh conditions. Whether heat treatment, metal processing, or laboratory furnaces, Heat radiation tubes are a critical element in the process of efficient, high-performance heating.

Heat Treatment Furnaces: Heat-emitting tubes are used extensively in carburizing and galvanizing furnaces, where even heating is necessary for the effective treatment of metals.

Melting and Dosing Furnaces: Tubes are also used in melting, dosing, and holding furnaces to provide a consistent supply of high temperatures efficiently for critical operations.

Conclusion

The inclusion of Heat-emitting tubes in industrial heating devices enhances the transfer of heat, raises the level of energy efficiency, and ensures longevity at high temperatures. The flexibility and resilience of Heat radiation tubes ensure their applicability across numerous applications ranging from heat treatment to melting furnaces. Marathon offers superior radiant tubes for high-quality, high-performance heating systems.