When Woolpad Makes Sense

After non-woven and fine abrasive discs: Once defects are minimized, woolpads help bring out luster and clarity on metals and finished woods.

For compounds and fine polishing stages: With hook-and-loop systems like Velcro Disc interfaces common in Supra’s lineup, swapping to a woolpad is quick and repeatable in production.

Benefits of Woolpad Discs

High cut-to-finish ratio in polishing: Wool’s fiber structure increases effective surface contact, enhancing polishing efficiency on metal and woodwork after non-woven blending.

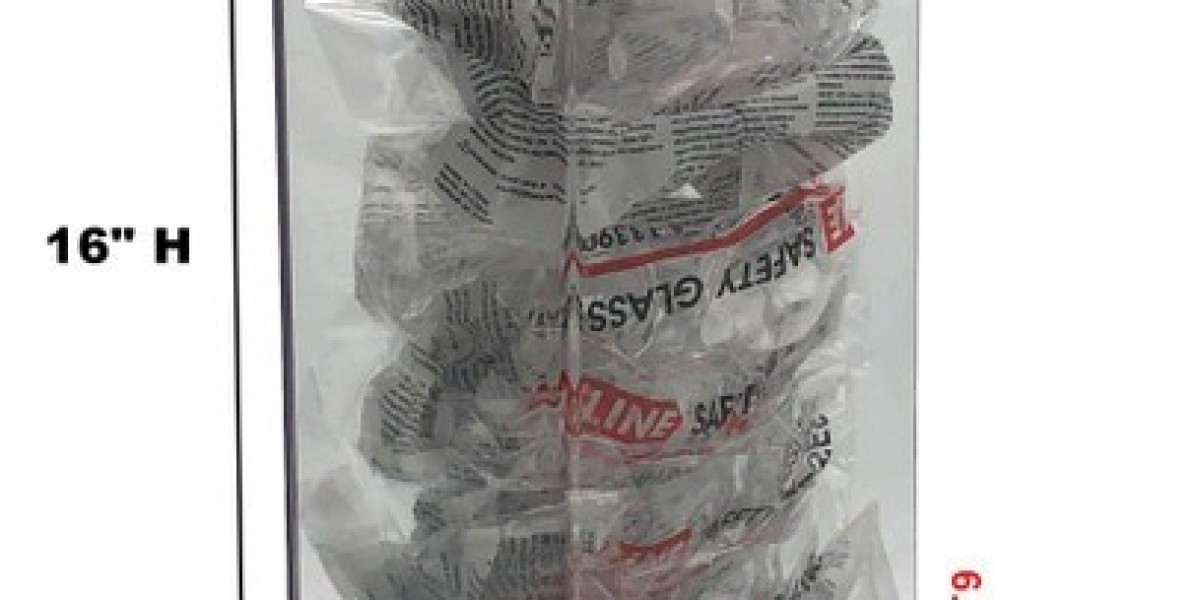

Compatible with Velcro-backed systems: Supra’s listing of Velcro Disc and EAZYCUT MAKE VELCRO BUFFING DISC GOLD underlines a workflow where quick-change backing simplifies pad transitions.

Metal vs Wood Considerations

On metals, ensure the pre-polish finish from Flap Disc and Abrasive Paper Disc is uniform to avoid highlighting scratches during woolpad polishing. On wood, prior sanding with PSA Sanding Disc or Abrasive Paper Disc sets the base; the woolpad then boosts sheen for clear coats or natural finishes.

Process Tips

Keep speeds and pressure moderate to maintain control and avoid swirl buildup, using quick-change Velcro interfaces to cycle pads efficiently.

Maintain pad cleanliness to prevent embedded debris from marring finishes, a best practice applicable across Velcro Disc and polishing accessories.

How It Fits Supra’s System

A coherent chain is: initial shaping with Fiber Disc or Flap Disc, refinement via Non Woven Wheel, pre-polish leveling with Abrasive Paper Disc or Velcro Disc, and final gloss with a woolpad polishing disc. This keeps the workflow within the product families Supra Industries makes available to industrial and workshop users.

Bottom Line

Woolpad polishing discs are ideal when finishing stages demand gloss and clarity, pairing naturally with Supra’s Velcro Disc and related abrasive families for streamlined, hook-and-loop polishing transitions in both metal and wood applications. They enhance productivity and finish quality once prior abrasive steps have prepared a uniform surface