The wind turbine gear oil market is rapidly evolving in response to the growing demand for reliable, efficient, and sustainable wind energy solutions. As turbine technologies become more advanced and environmental challenges intensify, the role of gear oils in maintaining turbine performance has never been more critical. New market trends are not only driving innovation in lubrication technology but are also reshaping the way operators approach turbine maintenance and energy efficiency.

Increasing Turbine Size Demands Better Lubrication

Modern wind turbines are being built larger and more powerful than ever before. These new-generation turbines are designed to operate at higher loads and under more stressful environmental conditions. As a result, traditional gear oils often fall short in meeting the rigorous demands of these machines. The market is responding with advanced synthetic and semi-synthetic oils that deliver superior thermal stability, wear protection, and resistance to oxidation—ensuring turbines run efficiently even under extreme pressures.

Longer Service Intervals and Operational Reliability

One of the most prominent trends shaping the market is the push for extended oil drain intervals. Wind farm operators aim to reduce maintenance downtime and increase operational uptime, especially for offshore installations where access is difficult and costly. Advanced gear oil formulations now enable longer intervals between oil changes without compromising on performance, thanks to improved oxidative resistance, enhanced anti-foam properties, and better water separation.

Emphasis on Energy Efficiency and Reduced Friction

In the quest to maximize energy output, every percentage of efficiency matters. Lubrication plays a significant role in reducing mechanical friction, which in turn decreases energy loss. New gear oil technologies are being engineered with low-viscosity, high-efficiency base stocks and additive systems that significantly reduce internal gearbox friction. This leads to smoother turbine operations, reduced wear and tear, and ultimately greater energy production.

Real-Time Monitoring and Condition-Based Maintenance

The integration of digital technologies and smart sensors in wind turbines is enabling condition-based maintenance (CBM) and real-time oil monitoring. Operators can now track key indicators such as viscosity, water contamination, and wear particles, enabling them to make informed decisions about oil changes and component replacements. As a result, demand is rising for gear oils that are compatible with monitoring technologies and that perform consistently under variable conditions.

Eco-Friendly and Biodegradable Lubricants

Environmental sustainability is a top priority in the renewable energy industry. In line with global emissions reduction goals and ecological safety regulations, there is increasing demand for biodegradable and environmentally acceptable lubricants (EALs). These lubricants reduce the environmental impact of oil leaks and spills, especially in offshore and coastal wind farms. Manufacturers are innovating with plant-based or synthetic ester formulations that offer both high performance and low environmental risk.

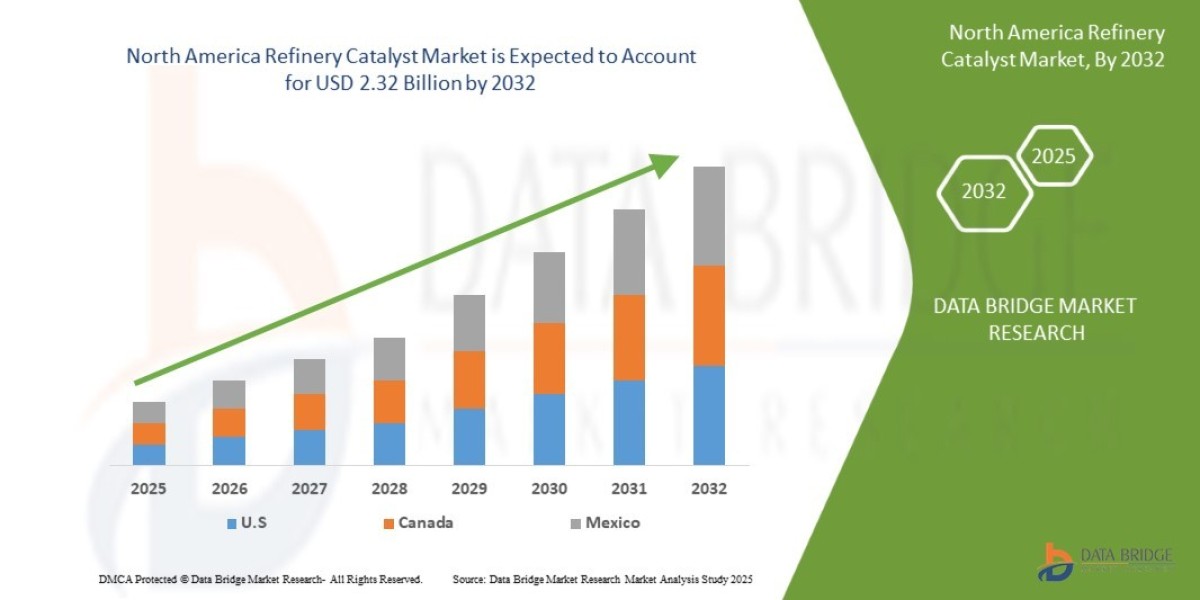

Regional Growth Trends and Market Dynamics

Asia-Pacific, led by China and India, is emerging as a key growth region due to the large-scale development of onshore wind farms and growing investments in clean energy infrastructure. Europe remains strong in offshore wind installations, especially in the North Sea region, pushing demand for high-durability gear oils that can withstand salty, humid conditions. Meanwhile, North America continues to see an uptick in wind energy investment, contributing to steady market expansion for lubrication solutions.

OEM and Regulatory Collaboration

Collaboration between wind turbine manufacturers (OEMs), gear oil producers, and regulatory agencies is becoming more common as the market matures. Lubricant suppliers are working closely with OEMs to develop gear oils that meet specific performance requirements for new turbine models. Additionally, gear oils must comply with increasingly stringent international standards related to environmental safety, toxicity, and biodegradability.

Competitive Innovation and Product Differentiation

Market competition is fueling innovation in gear oil chemistry. Companies are differentiating themselves with products that offer proprietary anti-wear additives, improved thermal and oxidative resistance, and extended service lifetimes. Others are investing in R&D to create smart lubricants—oils that adapt to changing operating conditions and deliver real-time feedback. The future of gear oil will likely involve a blend of chemical innovation and digital intelligence.

Future Outlook: Innovation Driving Sustainability

As the global energy transition accelerates, the wind turbine gear oil market will continue to be influenced by emerging technologies, stricter regulations, and the increasing complexity of wind turbines. The ability to deliver advanced lubrication solutions that enhance turbine efficiency, extend service life, and align with environmental priorities will define success in this space.

Manufacturers that stay ahead of these trends—by investing in R&D, prioritizing eco-friendly formulations, and aligning with turbine OEMs—will not only gain competitive advantage but also contribute significantly to the sustainability goals of the global energy sector.