In precision winding applications, achieving accurate material tracking and tension control is often a challenge that can be resolved by incorporating Banana Rollers into the production line.

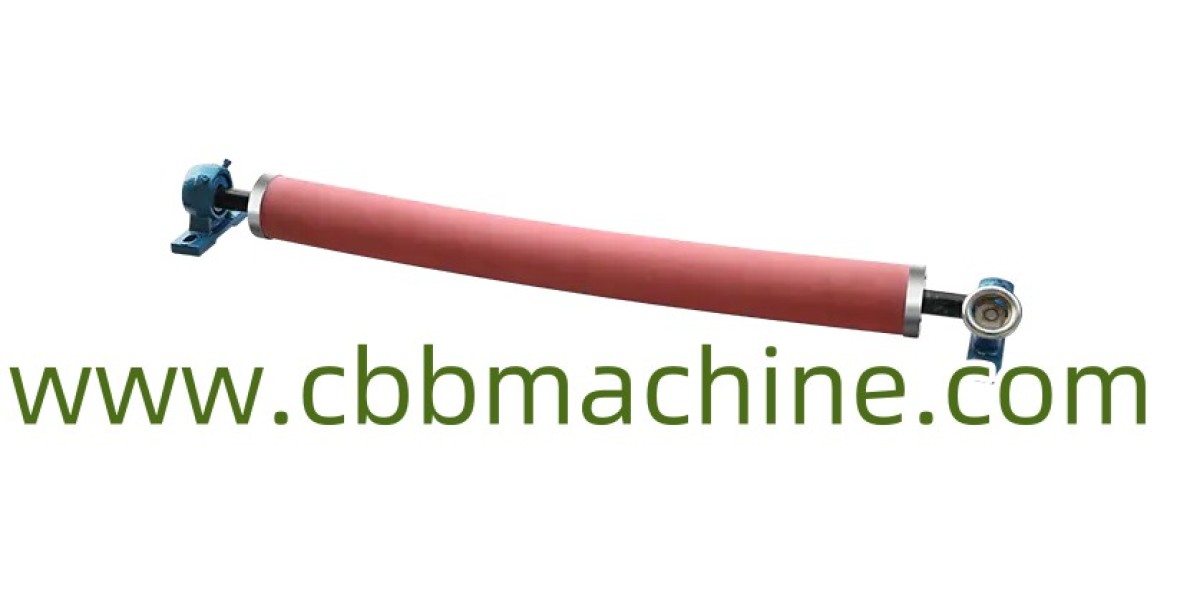

These specially designed rollers are slightly curved, allowing them to create a gentle spreading force across the web of materials like film, paper, textiles, or foil. The primary purpose of this structure is to eliminate wrinkles and maintain material flatness, which is critical in high-speed converting operations. Unlike flat rollers, the curved surface of banana rollers distributes pressure uniformly, preventing edge curling or folding.

Industries such as flexible packaging, printing, and coating heavily depend on smooth web handling to ensure that downstream processes function efficiently. Any imperfection introduced during unwinding or rewinding can cause issues with lamination, coating quality, or print alignment. By installing banana rollers at strategic points, manufacturers can guarantee uniform web tension and material distribution, ensuring better product consistency and minimal scrap.

One of the key benefits of these rollers lies in their adjustability. The curve angle, shaft length, and material can be customized based on the application. Some may require anti-static coatings, while others demand lightweight construction to reduce inertia. This flexibility means that banana rollers can be tailored to meet specific process demands, from delicate film to heavy-duty paper rolls.

When integrated into systems with tension sensors or servo-driven motors, banana rollers enhance overall automation performance. Their use supports stable web alignment during acceleration or deceleration, making them indispensable in modern production lines that prioritize speed and precision.

Durability is another advantage. High-quality banana rollers are manufactured using corrosion-resistant metals or anodized aluminum, offering long service life even in challenging industrial environments. Proper bearings and precision machining ensure smooth rotation and minimal maintenance over time.

Moreover, these rollers contribute to energy efficiency. By ensuring that the web runs flat without extra tension correction, they reduce wear on motors and drive systems. This not only extends equipment life but also lowers operational costs.

To ensure optimal results, it’s essential to choose banana rollers that match the exact needs of your process. Custom-engineered solutions provide better alignment and less downtime, improving overall equipment effectiveness (OEE).

To explore detailed specifications or request tailored configurations, please visit https://www.cbbmachine.com/product/banana-roller/customizable-banana-roller.html