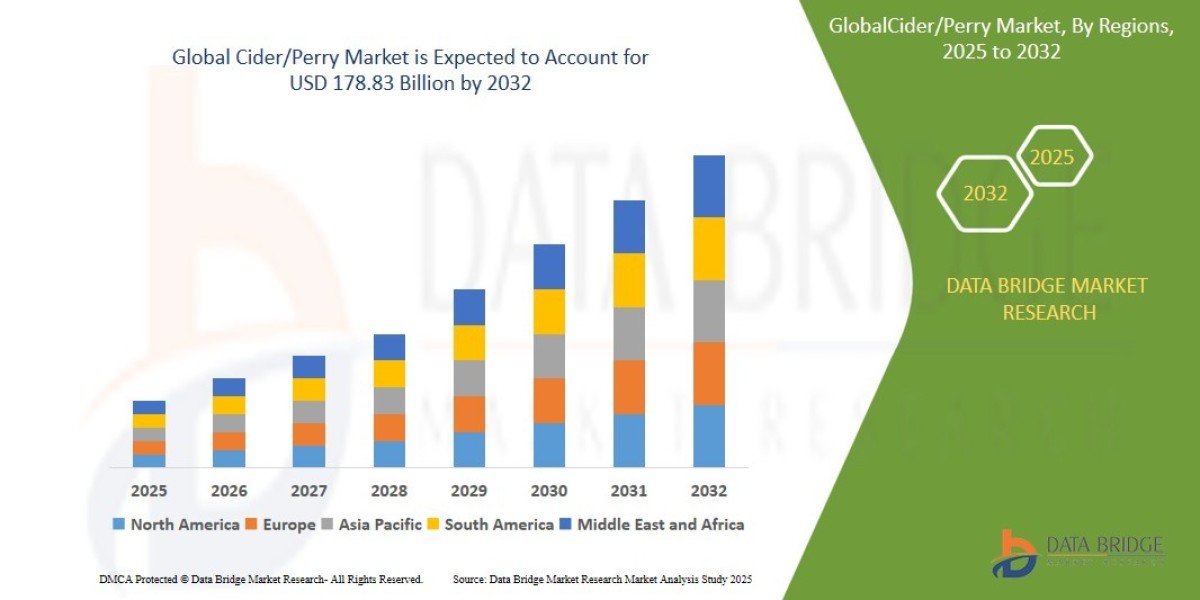

"Detailed Analysis of Executive Summary Cider/Perry Market Size and Share

CAGR Value

The Global Cider/Perry Market size was valued at USD 102.32 billion in 2024 and is expected to reach USD 178.83 billion by 2032, at a CAGR of 6.4% during the forecast period.

This Cider/Perry Market report serves you with the bigger picture of the marketplace as it studies market and the industry by considering several aspects. This market report gives an absolute background analysis of the industry along with an assessment of the parental market. To achieve sustainable growth in the market, businesses must be well-versed with the specific and most relevant product and market information in the Cider/Perry Market The resources used for collecting the data and information that is included in this report are very trustworthy and range from journals, company websites, and white papers etc.

Being professional and comprehensive, this Cider/Perry Market report focuses on primary and secondary drivers, market share, leading segments, possible sales volume, and geographical analysis. This market report also analyzes the market status, market share, current trends, growth rate, future trends, market drivers, opportunities and challenges, risks and entry barriers, sales channels, and distributors. The Cider/Perry Market report clearly explains what market definition, classifications, applications, engagements and market trends are for the Cider/Perry Market industry. This market report provides explanation about the detailed market analysis with inputs from industry experts. The Cider/Perry Market report presents data on patterns and improvements, and target business sectors and materials, limits and advancements.

Take a deep dive into the current and future state of the Cider/Perry Market. Access the report:

https://www.databridgemarketresearch.com/reports/global-cider-perry-market

Cider/Perry Market Data Summary

**Segments**

- **Type**: The cider/perry market can be segmented based on type into cider and perry. Cider is a beverage made from fermented apple juice, while perry is a similar drink made from fermented pear juice. Both products offer a variety of flavors and styles to cater to different consumer preferences.

- **Distribution Channel**: Another important segment of the global cider/perry market is based on the distribution channel. This includes on-trade channels such as bars, restaurants, and cafes, as well as off-trade channels which cover retail stores, supermarkets, and online platforms. The choice of distribution channel plays a crucial role in reaching target consumers effectively.

- **Packaging Type**: Packaging type is also a significant segment in the cider/perry market. Products are available in various packaging formats such as bottles, cans, and kegs. The convenience, sustainability, and visual appeal of the packaging play a key role in consumer purchase decisions.

**Market Players**

- **Heineken N.V.**: Heineken is a major player in the global cider/perry market, offering a range of popular cider brands such as Strongbow and Bulmers. The company's strong distribution network and marketing strategies have helped establish its presence in key markets worldwide.

- **The Boston Beer Company**: The Boston Beer Company is another key player in the cider/perry market with its Angry Orchard brand. The company focuses on innovation and quality to appeal to a diverse consumer base, driving growth and market share.

- **Aspall Cyder Ltd.**: Aspall Cyder is known for its premium cider products made from locally sourced ingredients. The company's commitment to traditional craftsmanship and unique flavors has garnered a loyal customer following and positioned it as a competitive player in the market.

- **C&C Group plc**: C&C Group is a leading producer of cider and other alcoholic beverages, with brands such as Magners and Hornsby's. The company's strong distribution capabilities and product innovation have contributed to its success in the global cider/perry market.

- **SABMiller plc**: SABMiller, before being acquired by Anheuser-Busch InBev, was a significant player in the cider/perry market with brands like Kopparberg and Miller's Harvest. The company's diversified product portfolio and global reach helped it maintain a strong market position.

The global cider/perry market is a dynamic industry characterized by innovation, changing consumer preferences, and evolving market trends. Key players continue to invest in product development, marketing strategies, and expansion into new markets to stay competitive and drive growth. With a focus on quality, diversity, and sustainability, the market is expected to witness further expansion and consolidation in the coming years.

The global cider/perry market is experiencing a shift towards premiumization, with consumers becoming increasingly interested in craft ciders and products with unique and innovative flavors. This trend is driven by a growing demand for high-quality beverages that offer a more artisanal and authentic taste experience. Market players are responding to this trend by focusing on product innovation and differentiation to stand out in a competitive landscape. As consumers seek out new and exciting flavor profiles, producers are experimenting with a variety of ingredients and methods to create distinctive offerings that appeal to a diverse range of tastes.

Furthermore, sustainability is emerging as a key factor influencing consumer preferences in the cider/perry market. With a rising awareness of environmental issues and a growing emphasis on eco-friendly practices, consumers are showing a preference for products that are produced using sustainable methods and packaging. Market players are increasingly incorporating sustainability practices into their production processes, from sourcing ingredients locally to reducing carbon footprints in manufacturing and distribution. Brands that align with consumer values around sustainability are likely to gain a competitive edge and attract a loyal customer base.

The market is also witnessing a trend towards experiential consumption, with consumers looking for immersive and engaging experiences beyond just the product itself. This shift is driving the rise of cider tourism, with cider mills and breweries offering tours, tastings, and events to educate consumers about the production process and create memorable experiences. By connecting with consumers on a deeper level and building a sense of community around their brands, market players can forge stronger relationships and foster brand loyalty.

In terms of distribution channels, e-commerce is playing an increasingly important role in the cider/perry market. The convenience and accessibility of online platforms have made it easier for consumers to discover and purchase a wide range of cider products from across the globe. Market players are leveraging e-commerce channels to reach a broader audience and engage with consumers directly, bypassing traditional retail channels. This shift towards online sales is expected to continue growing, offering new opportunities for market players to expand their reach and increase sales.

Overall, the global cider/perry market is a dynamic and evolving industry driven by changing consumer trends and preferences. Market players that prioritize innovation, sustainability, and consumer engagement are well-positioned to succeed in a competitive market environment. By staying attuned to market dynamics and adapting to shifting consumer demands, brands can carve out a niche for themselves and thrive in a rapidly evolving market landscape.The cider/perry market continues to experience a shift towards premiumization as consumers display a growing interest in craft ciders and unique flavor profiles. This trend towards premiumization is driven by a desire for high-quality beverages that offer a more artisanal and authentic taste experience, reflecting evolving consumer preferences for sophisticated and innovative products. Market players are responding to this trend by focusing on product innovation and differentiation to set themselves apart in a competitive market landscape. The emphasis on unique and diverse flavor offerings has become a key strategy for companies looking to capture the attention of consumers seeking novel taste experiences.

Additionally, sustainability has emerged as a crucial factor influencing consumer choices within the cider/perry market. With an increasing awareness of environmental issues and a significant focus on eco-friendly practices, consumers are actively seeking out products that are produced using sustainable methods and packaging. Market players are incorporating sustainability practices into their production processes, from sourcing locally grown ingredients to reducing carbon footprints in manufacturing and distribution. Brands that align with consumer values around sustainability have the potential to gain a competitive advantage and attract a loyal customer base.

Moreover, there is a noticeable trend towards experiential consumption within the cider/perry market, with consumers seeking immersive and engaging experiences beyond just the product itself. This shift has led to the rise of cider tourism, where cider mills and breweries offer tours, tastings, and events to educate consumers about the production process and create memorable experiences. By establishing deeper connections with consumers and fostering a sense of community around their brands, market players can strengthen relationships and build brand loyalty in a competitive market environment.

Furthermore, e-commerce is playing a significant role in shaping the distribution channels within the cider/perry market. The accessibility and convenience of online platforms have made it easier for consumers to explore and purchase a wide variety of cider products from around the world. Market players are leveraging e-commerce channels to broaden their audience reach and directly engage with consumers, circumventing traditional retail channels. The increasing shift towards online sales presents new growth opportunities for market players to expand their market reach and drive sales by capitalizing on the digital marketplace.

In conclusion, the global cider/perry market is characterized by dynamic consumer trends, with a focus on premiumization, sustainability, experiential consumption, and e-commerce. Market players that prioritize innovation, sustainability, and consumer engagement are strategically positioned to thrive in a competitive market landscape. By staying adaptable to evolving consumer preferences and market dynamics, brands can differentiate themselves and carve out a unique position in the ever-changing cider/perry market.

Investigate the company’s industry share in depth

https://www.databridgemarketresearch.com/reports/global-cider-perry-market/companies

Cider/Perry Market Overview: Strategic Questions for Analysis

- What is the size of the global Cider/Perry Market industry this year?

- What rate of growth is forecasted for the next decade for Cider/Perry Market?

- What are the key divisions of the Cider/Perry Market?

- Which organizations have the strongest presence in Cider/Perry Market?

- Which markets are the focus of the geographic analysis for Cider/Perry Market ?

- What companies are featured in the competitive landscape for Cider/Perry Market?

Browse More Reports:

Europe Optical Wavelength Services Market

Asia-Pacific Antimicrobial Coating for Medical Devices Market

Global Hydrocarbon Solvents Market

Global Plant-Based Textile Yarn Market

North America Hernia Mesh Repair Devices Market

North America Blood Culture Test Market

Global Stroke Diagnostics Market

North America Structural Health Monitoring Market

Global Optical Lens Edger Market

Global Paprika Powder Market

Asia-Pacific Hernia Mesh Repair Devices Market

Global Docosahexaenoic Acid Market

Global Presbyopia Market

Global Vertebroplasty and Kyphoplasty Market

Global Optical Wavelength Services Market

Europe Antimicrobial Coating for Medical Devices Market

Global Liquid On Silicon (Lcos) Front Projection Market

Global Depyrogenated Sterile Empty Vials Market

Global Cold Agglutinin Disease Market

Global Sericulture Market

Asia-Pacific Stroke Diagnostics Market

Global Environmental Test Chambers Market

Global Vacuum Evaporators Market

Global Automotive Tie Rod Assembly Market

Global Processed Meat Speciation Testing Market

Middle East and Africa Attitude and Heading Reference Systems (AHRS) Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com

"