Traditional concrete coatings and treatment are often less when it comes to providing long -lasting, impenetrable protection against these countless dangers. This is the place where high-density polyethylene (HDPE) T-rib lining appears as a game switch, and offers a better and remarkably durable concrete safety solution.

The Genesis of Superior Protection

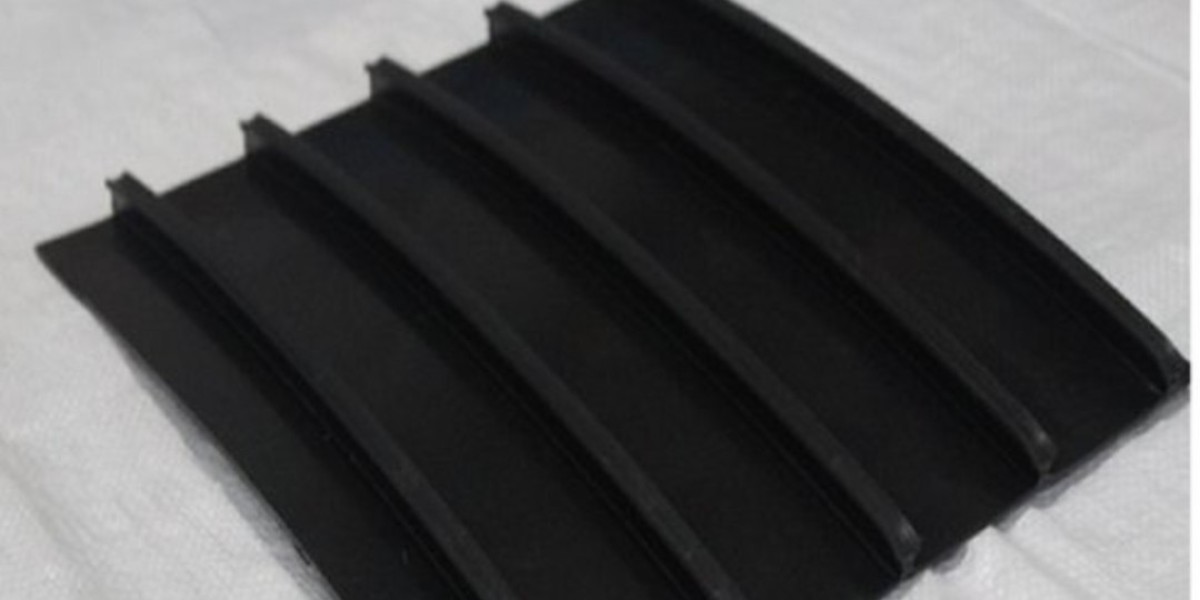

The concept of HDPE R-rib liner sheets is elegant, but still incredibly effective. These sheets are built by the virgin HDPE resin, and have extraordinary chemical resistance, friction resistance and imperfection. The peculiar feature, "T-ribs" (or "R-rib", as they are sometimes known, leads the interchangeable words to HDPE R-R-rib-lining tabs), strategically designed the appearance built into wet concrete during the casting process.

Unrivaled Durability and Chemical Resistance

HDPE is known for its passivity, from which it is very resistant to a spacious selection of anestheal chemicals, including acids, alkalis, salts and various hydrocarbons. This makes an ideal choice for applications where concrete is exposed to aggressive industrial waste, agricultural waste or even acidic groundwater. Unlike concrete, which can degrade and split back when exposed to such substances, the HDPE liner remains unaffected, retaining the structural integrity of the underlying concrete for decades. This extended life is translated into significant long -term cost savings by reducing the needs of maintenance and expensive repair.

Abrasion Resistance and Impact Strength

Out exempt slices, high road currents and even pedestrians or vehicle traffic can cause gradual erosion of solid surfaces. HDPE t rib liner manufacturer feeding sheets shows excellent friction resistance, which is better than concrete. This makes them suitable for applications such as sewage lines, culverts and ducts where grinding materials are carried. In addition, the underlying flexibility and cruelty of HDPE provides a degree of effect resistance, providing an extra layer of protection against accidental damage.

Addressing the Impermeability Challenge

Concrete is by nature a porous material. It seems solid, it contains microscopic capillaries that can allow water penetration and dissolve pollution contamination. This permeability can cause ribbar corrosion, freezing milk damage and eventually, structural decline. The HDPE T-RB liner sheet, which is completely non-disciplinary, creates a completely impenetrable barrier. This not only prevents the introduction of harmful substances, but also ensures control in applications where it is important to prevent leakage, for example in secondary control systems for hazardous materials or in drinking water reservoirs where it is important to maintain water quality.

Installation and Versatility

The MAHIRA POLYGLOBAL LLP preparation is usually installed by experienced professionals, and the process is relatively right. The sheets are distributed in the shape work before inserting the concrete. When the concrete is placed and vibrated, the ribs are built in. For pre -designated concrete elements, the lining can be inserted directly into sections of the production plant. The versatility of these sheets is another important advantage. They can be coined in different thickness and shape to fit specific project requirements. In addition, welding techniques can be used to create constant, spontaneous lining in large areas, which eliminate potentially weak points that may be present with traditional joint systems. This allows complex geometric and connection to be fully preserved.

A Sustainable Choice

In a time of increasing environmental awareness, the stability aspects of building materials are prominent. HDPE is a thermoplastic material, which means it can be recycled. The long life of HDPE T-rib lining plates also contributes to stability by continuously repairing and reducing the need for compensation, which reduces consumption and waste production of materials in the life of a structure. This obligation for long life and resource efficiency makes them a responsible alternative for modern infrastructure projects. The strong nature of the HDPT RIB liner means less often interventions, contributing to low -carbon footprints over time.

Conclusion

HDPE T-rib Lining sheets represent an important leap in specific conservation technology. Combining their unique anchoring systems, underlying durability, chemical resistance and imperfection of HDPE t rib liner provides a better and long -lasting solution for a wide range of requirements that require applications. From the protection of significant infrastructure to extending the life of industrial plants, these lines provide an uncontrolled shield against properly solid security, and declining forces. The idea of HDPE R-R-rib Lining sheets, which requires solid integrity and long life for any project, is not just an alternative, but a sound and further thinking is necessary.

Frequently Asked Questions

Question: What are the primary benefits of using HDPE T-rib lining on traditional concrete coatings?

A: The main advantage is better mechanical bonds achieved through built-in T-ribs, which do not ensure any deletion, are combined with excellent chemical resistance, friction resistance and complete imperviousness of HDPE. Traditional coatings often fail due to chemical attacks, friction or exfoliation over time.

Question: How is the integrity of HDPE T-rib feeding sheets on joints and penetration?

A: Integrity of joints and entrance is maintained through special welding techniques. Thermal welding creates a constant, homogeneous binding between welding sheets, while tailor -made fittings and shoes are used for pipe penetration, ensuring a comfortable and fully protected lining system.

Question: Who is the largest manufacturer of HDPE T-Rib Liner Sheets?

A: While identifying a single "largest" manufacturer globally is difficult without specific market share data, Mahira Polyglobal LLP is a prominent manufacturer and exporter of HDPE T-Rib Liner Sheets, known for its quality products.