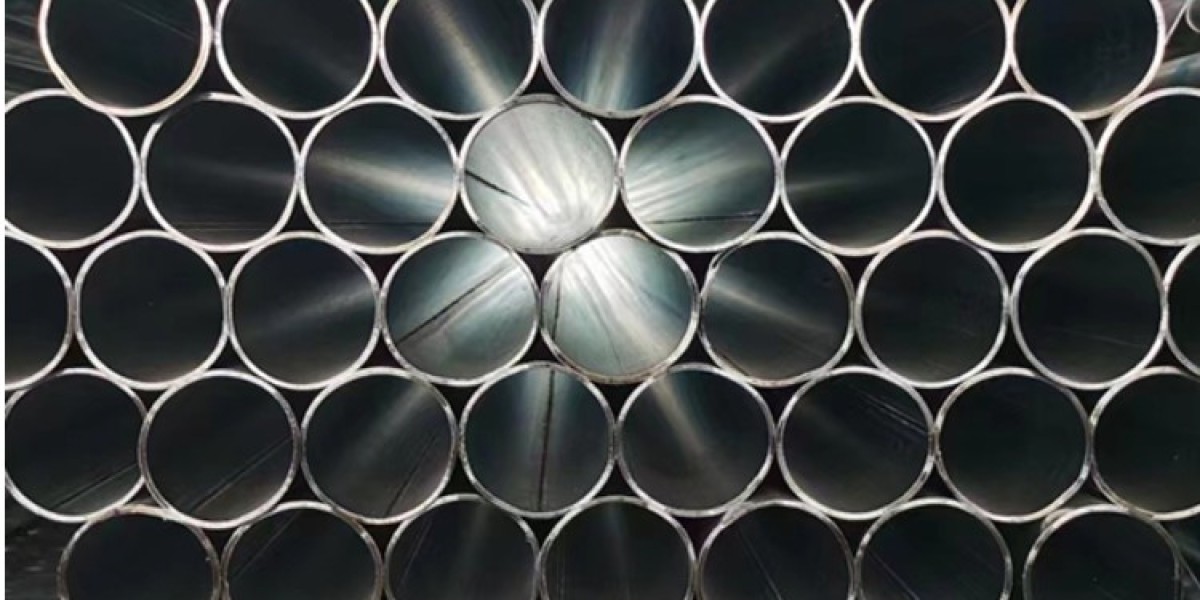

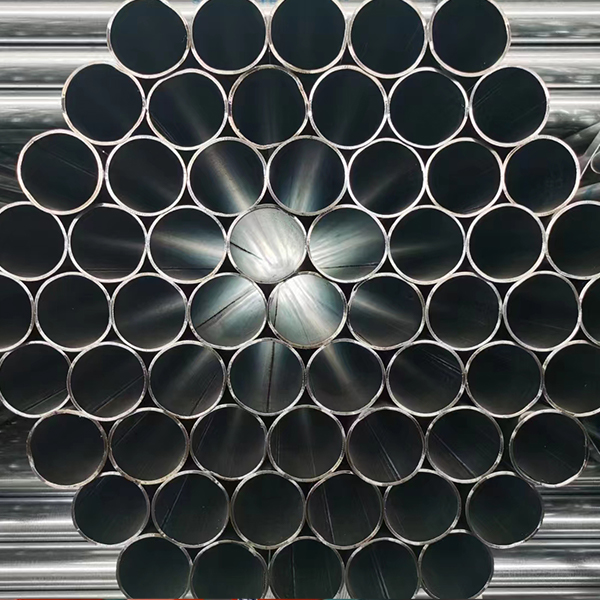

The aggressive environments of chemical processing and food production demand materials that withstand constant exposure to corrosive substances while maintaining structural integrity. Stainless steel pipes excel in these challenging conditions due to their alloy composition and surface properties, offering long-term reliability where lesser materials would rapidly degrade. This corrosion resistance stems from a self-repairing chromium oxide layer that forms naturally on the steel’s surface, providing continuous protection against chemical attacks.

In chemical plants, stainless steel piping systems handle everything from concentrated acids to alkaline solutions. Grade 316L stainless steel, with its molybdenum content, demonstrates exceptional resistance to chloride-induced pitting—a critical property for equipment exposed to seawater-cooled systems or chlorine-based compounds. Duplex stainless steels (e.g., 2205) are increasingly specified for high-stress corrosive environments, combining strength with resistance to stress corrosion cracking. These materials enable safe transport of hazardous chemicals at elevated temperatures and pressures, minimizing leakage risks and maintenance downtime.

Food processing facilities present a different corrosion challenge: organic acids and cleaning agents. Stainless steel pipes in citrus juice production lines resist citric acid erosion while preventing metallic contamination of products. Breweries utilize passivated stainless steel tubing to maintain pH stability during fermentation and prevent iron pickup that could alter beer flavor profiles. The material’s non-reactive nature ensures compliance with food contact regulations, even when processing highly acidic ingredients like tomatoes or vinegar-based products.

Surface treatments enhance stainless steel’s natural corrosion resistance for specialized applications. Electropolishing not only improves cleanability but also thickens the passive oxide layer, particularly beneficial for equipment exposed to dairy products or pharmaceutical solutions. Some processors apply proprietary coatings to handle extreme conditions, such as concentrated sulfuric acid transfer lines in petrochemical refineries.

The marine food processing sector exemplifies stainless steel’s dual corrosion resistance capabilities. Pipes in seafood plants withstand saltwater exposure during product rinsing while resisting decomposition byproducts from marine organisms. Grade 904L stainless steel has gained popularity in these applications due to its superior resistance to both chloride and sulfide corrosion, extending equipment lifespan in coastal facilities.

Maintenance considerations further underscore stainless steel’s value in corrosive environments. Unlike carbon steel pipes requiring frequent protective coatings, properly specified stainless systems maintain performance with minimal intervention. This reliability reduces lifecycle costs despite higher initial investment, making it the economical choice for mission-critical applications. As industries continue to push operational boundaries with stronger cleaning agents and complex chemical processes, advanced stainless steel alloys remain essential for safe, durable fluid handling solutions.